A method for preparing sponge titanium by molten salt electrolysis in a resistance furnace

A molten salt electrolysis and resistance furnace technology, applied in the field of smelting, can solve the problems of poor corrosion resistance of high temperature molten salt, poor vacuum sealing, etc., and achieve the effects of low equipment loss and consumption, high sealing, and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

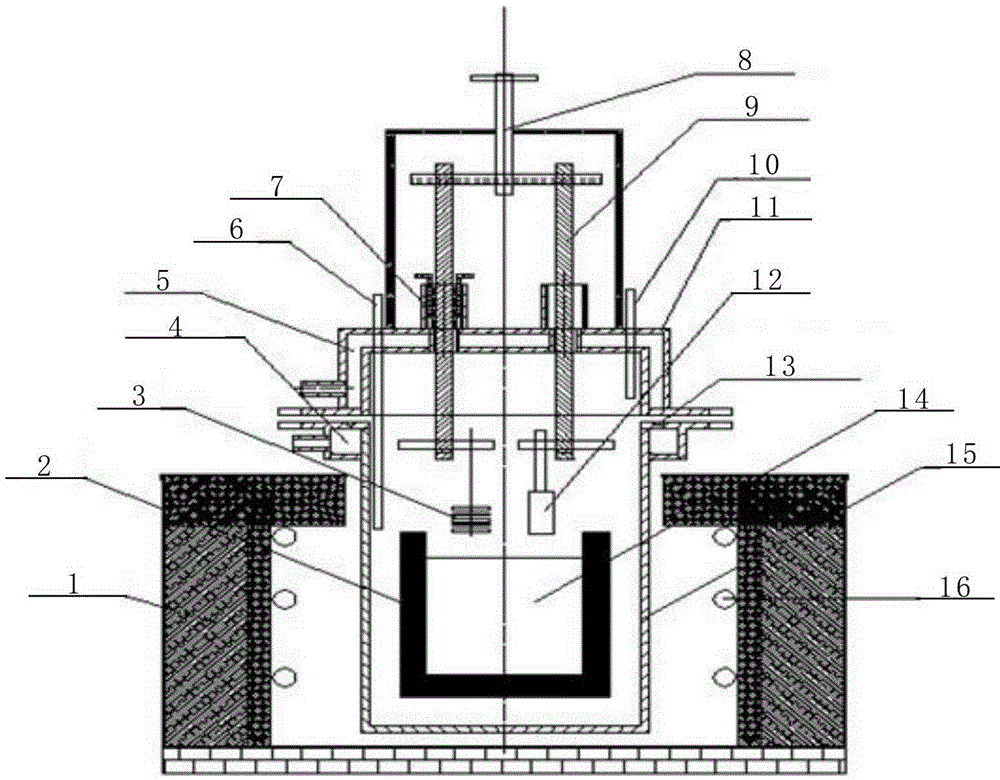

[0019] The present invention is a method for preparing sponge titanium by molten salt electrolysis in a resistance furnace, and is also one of the expansion methods of molten salt electrolysis in molten salt electrolysis. This method can prepare a small amount of sponge titanium. This is because the graphite crucible Limited by the capacity of the graphite crucible, if the capacity of the graphite crucible is increased, the preparation amount of the sponge titanium can also be increased, which is obvious to the art.

[0020] The resistance furnace 1 is equipped with a silicon carbide rod 16 as a heating element. The maximum temperature of the resistance furnace 1 is not lower than 950°C. The molten salt electrolysis method involves the graphite crucible 2, and the graphite crucible 2 stores calcium chloride molten salt 14, chlorine It is advisable that the storage capacity of calcium oxide molten salt 14 accounts for 2 / 3 of the capacity of graphite crucible 2, titanium dioxide ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com