Preparation method of high temperature CMAS and rain corrosion-resistant composite thermal barrier coating

A technology of thermal barrier coating and high temperature resistance, applied in coating, metal material coating process, fusion spraying, etc., can solve problems such as film cracking, shortening the service life of thermal barrier coating, and large difference in thermal expansion coefficient. Achieve cost reduction, improve CMAS corrosion resistance, and improve corrosion resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

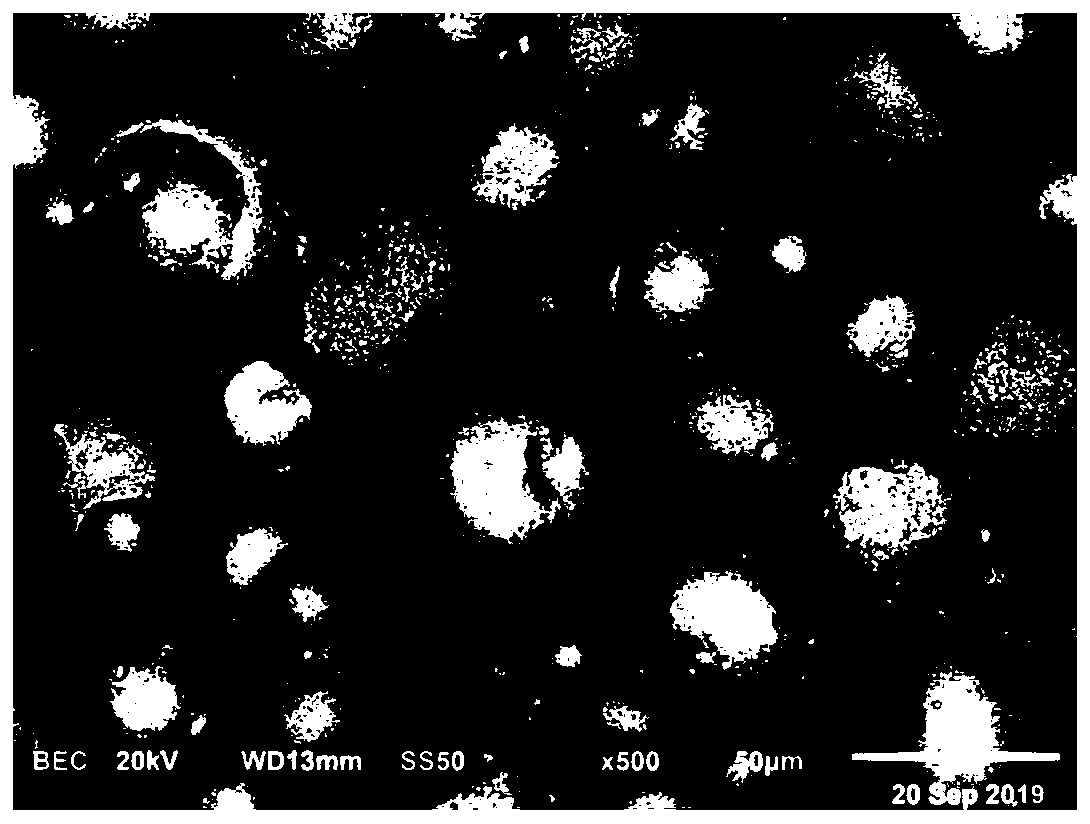

[0037] Step 1: Formulating Gd for Plasma Spraying 2 Zr 2 o 7 / Al 2 o 3 compound powder;

[0038] Gd with a particle size ranging from 15 to 30 microns 2 Zr 2 o 7 Powder, Al with particle size ranging from 0.06 to 1 micron 2 o 3 The powder is evenly mixed into a mixed powder. Among them, Al 2 o 3 Powder accounted for 10% by mass of the total mass of raw material powder, Gd 2 Zr 2 o 7 Powder accounted for 90% by mass of the total mass of raw material powder, Gd 2 Zr 2 o 7 and Al 2 o 3 The mass ratio between them is 90:10, and then uniformly mixed into the mass percentage is mixed powder: polyvinyl alcohol = 99:1 binder, mechanically mixed and stirred for 100 minutes, and then ultrasonically oscillated for 20 minutes. This is formulated as Gd for plasma spraying 2 Zr 2 o 7 / Al 2 o 3 compound powder;

[0039] The second step: pretreatment of metal matrix materials:

[0040] Sandblasting is performed on the surface of the GH3044 nickel-based superalloy to ...

Embodiment 2

[0051] Step 1: Formulating Gd for Plasma Spraying 2 Zr 2 o 7 / Al 2 o 3 compound powder;

[0052] Gd with a particle size ranging from 15 to 30 microns 2 Zr 2 o 7 Powder, Al with particle size ranging from 0.06 to 1 micron 2 o 3 The powder is evenly mixed into a mixed powder. Among them, Al 2 o 3 Powder accounted for 15% by mass of the total mass of raw material powder, Gd 2 Zr 2 o 7 Powder accounted for 85% by mass of the total mass of raw material powder, Gd 2 Zr 2 o 7 and Al 2 o 3 The mass ratio between them is 85:15, and then uniformly mixed into the mass percentage of powder: polyvinyl alcohol = 99:1 binder, mechanically mixed and stirred for 100 minutes, and then ultrasonically oscillated for 20 minutes, thus Formulated as Gd for plasma spraying 2 Zr 2 o 7 / Al 2 o 3 compound powder;

[0053] The second step: pretreatment of metal matrix materials:

[0054] The surface of the GH3044 nickel-based superalloy to be coated is sandblasted, and then the...

Embodiment 3

[0060] Step 1: Formulating Gd for Plasma Spraying 2 Zr 2 o 7 / Al 2 o 3 compound powder;

[0061] Gd with a particle size ranging from 15 to 30 microns 2 Zr 2 o 7 Powder, Al with particle size ranging from 0.06 to 1 micron 2 o 3 The powder is evenly mixed into a mixed powder. Among them, Al 2 o 3 Powder accounted for 20% by mass of the total mass of raw material powder, Gd 2 Zr 2 o 7 Powder accounted for 80% by mass of the total mass of raw material powder, Gd 2 Zr 2 o 7 and Al 2 o 3 The mass ratio between them is 80:20, and then uniformly mixed into the mass percentage of powder: polyvinyl alcohol = 99:1 binder, mechanically mixed and stirred for 100 minutes, and then ultrasonically oscillated for 20 minutes, thus Formulated as Gd for plasma spraying 2 Zr 2 o 7 / Al 2 o 3 compound powder;

[0062] The second step: pretreatment of metal matrix materials:

[0063] The surface of the GH3044 nickel-based superalloy to be coated is sandblasted, and then the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com