Oil well pump and manufacturing method thereof

A technology for oil well pumps and pump barrels, which is applied to pumps, pump components, variable capacity pump components, etc., which can solve the problems of low service life and loss of oil well pumps, and achieve extended service life, high friction and wear resistance, and high temperature resistance strong corrosion effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

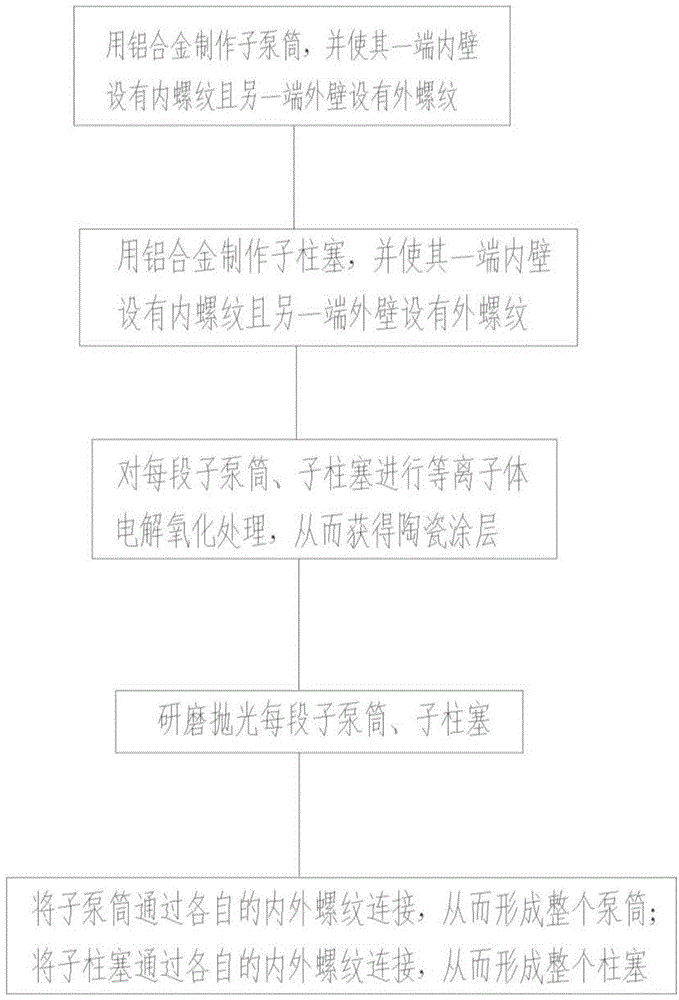

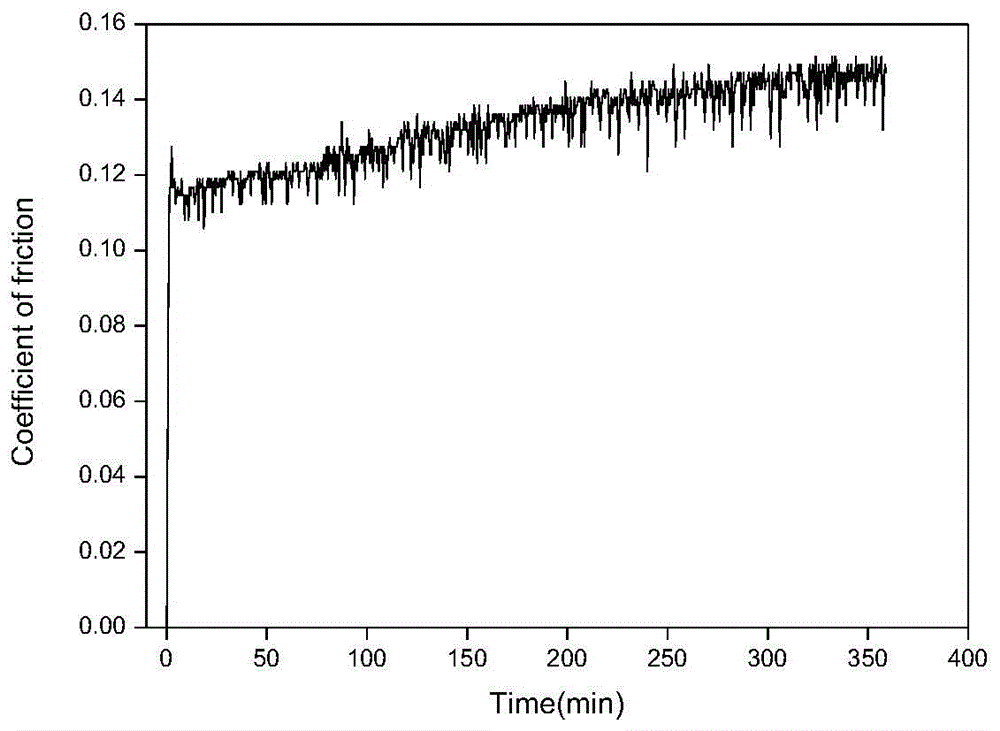

[0015] The oil well pump includes a pump cylinder and a plunger, ceramic coatings are respectively provided on the inner and outer walls of the pump cylinder, and ceramic coatings are respectively provided on the inner and outer walls of the plunger.

[0016] Since the inner and outer walls of the pump barrel are respectively provided with ceramic coatings, and the inner and outer walls of the plunger are respectively provided with ceramic coatings, and the ceramic coating is a very dense structure, so the high temperature corrosion resistance of the oil well pump is guaranteed. Strong, high friction and wear resistance, greatly extended service life.

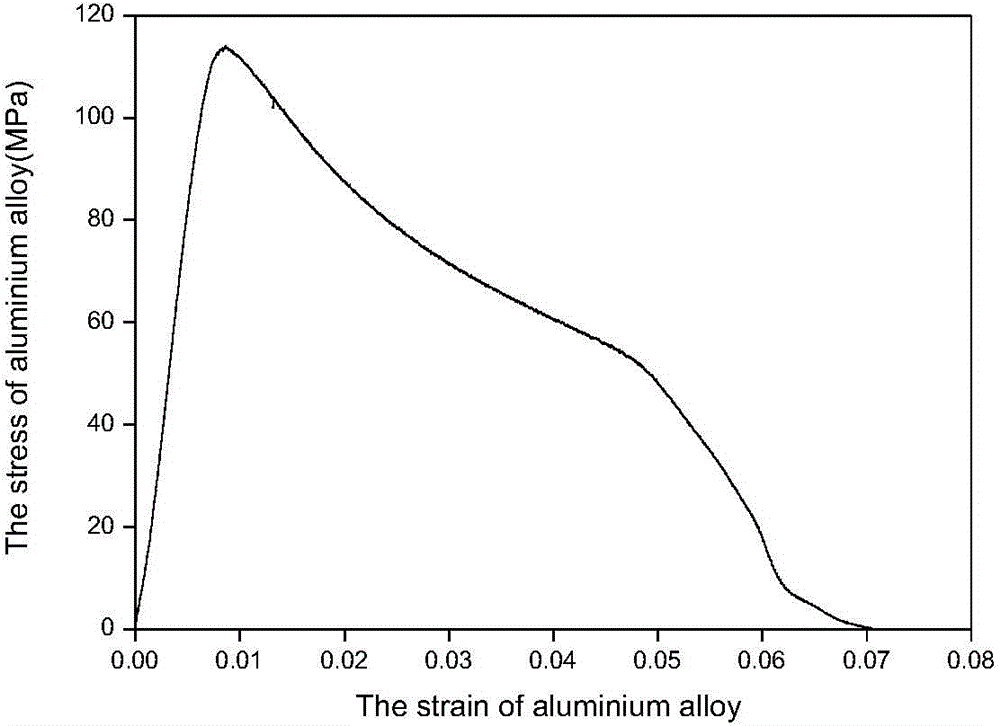

[0017] In addition, the pump barrel and the plunger are all aluminum alloys (the reasons for choosing high-strength aluminum alloys are: 1. Aluminum alloys can be subjected to plasma electrolytic oxidation treatment, which is the best way to prepare dense Al alloys. 2 o 3 One of the necessary conditions for ceramic coating; 2....

PUM

| Property | Measurement | Unit |

|---|---|---|

| yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com