Minitype double-diaphragm electromagnetic valve

A solenoid valve and double-diaphragm technology, applied in the field of miniature double-diaphragm solenoid valves, can solve the problems of chemical corrosion resistance, difficulty in realizing three-way valves, and increased costs, and achieve low cost, simple structure, and long service life.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The present invention will be described in further detail below in conjunction with accompanying drawing:

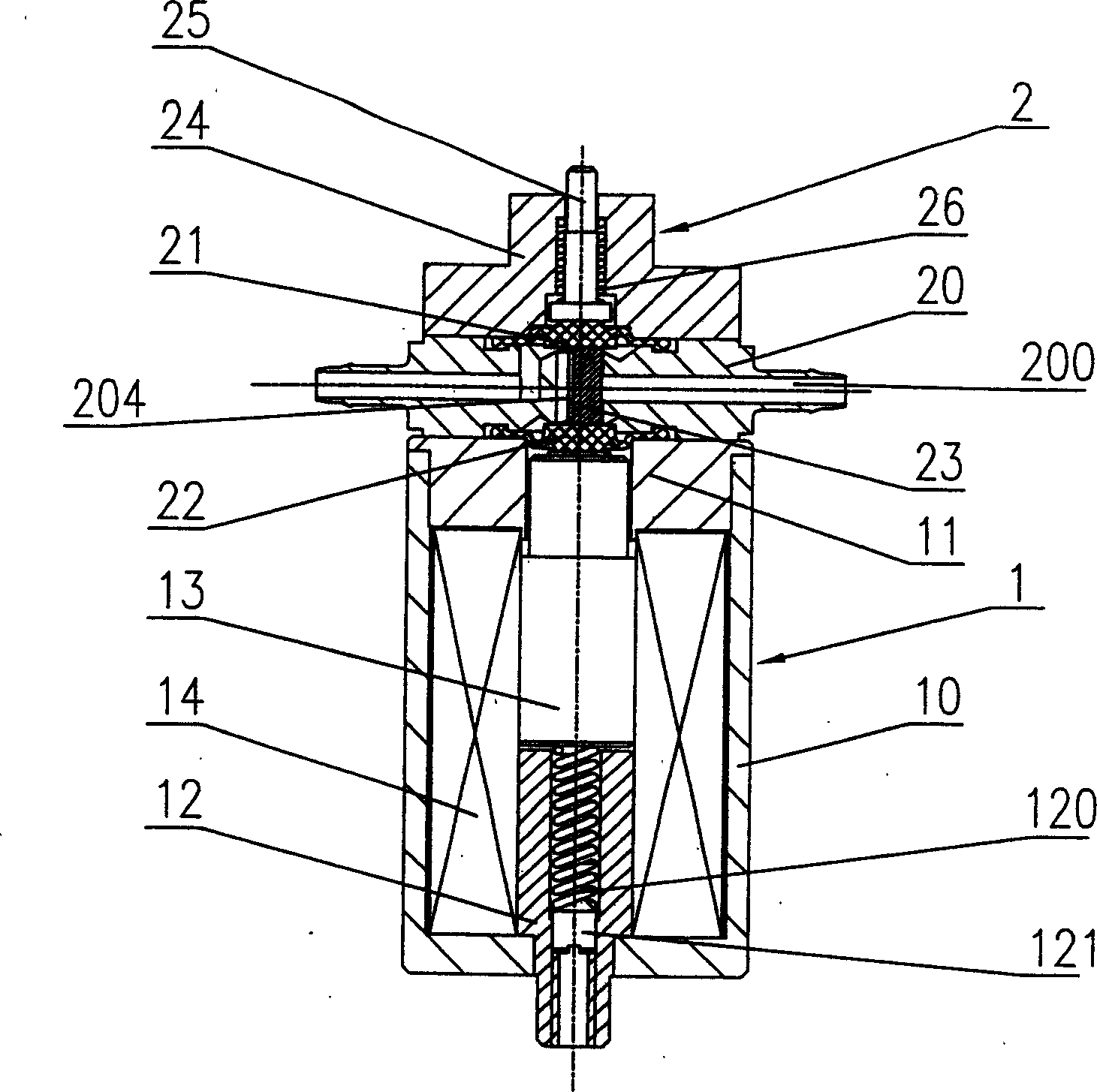

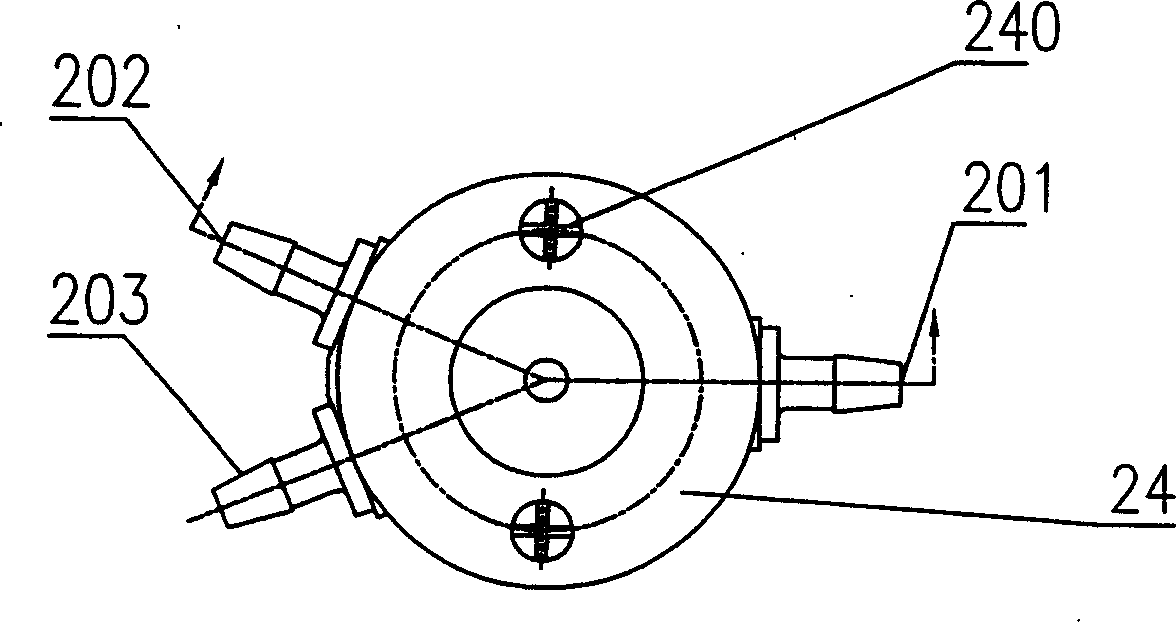

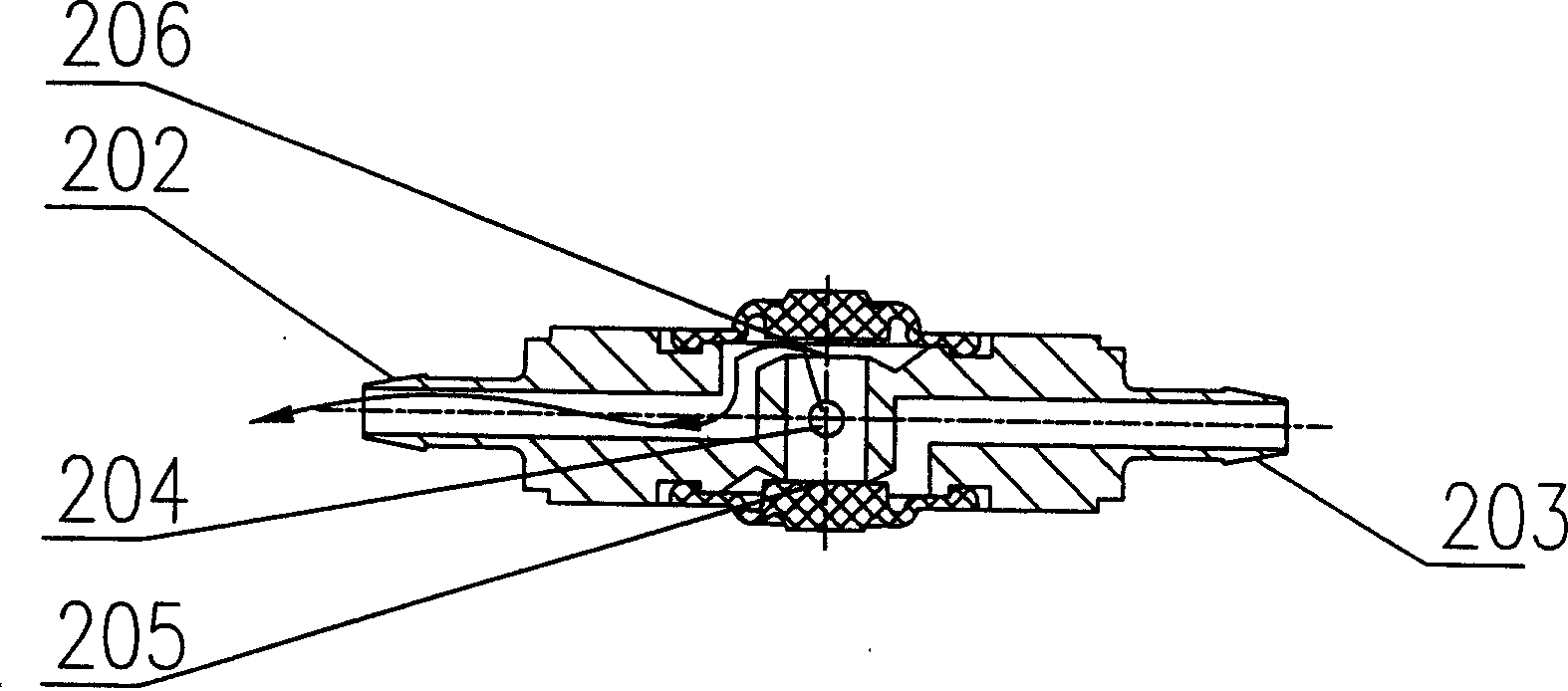

[0038] figure 1 , figure 2 , image 3 , Figure 4 , Figure 9 , Figure 10 The first embodiment of the present invention (utility model) is shown.

[0039] This miniature double-diaphragm solenoid valve with fluid medium self-control equipment is assembled by an electromagnetic assembly 1 and a valve body assembly 2 . The electromagnetic assembly 1 consists of the valve sleeve 10, the through hole 101 provided at the bottom of the valve sleeve 10, the hollow iron stopper 12 extending out of the through hole 101, the lower spring 120 of the inner hole of the hollow iron stopper 12, and the lower spring 120 for adjusting the lower spring. The hexagonal countersunk head screw 121 of the deformation amount, the valve core 13 at the upper end of the hollow iron stopper 12, the electromagnetic coil 14 sleeved between the valve sleeve 10, the valve core 13 and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com