A kind of high temperature resistant vacuum electroplating uv coating and its preparation method and application

A technology of vacuum electroplating and high temperature resistance, which is applied in the field of coatings, and can solve problems such as softening of the coating film, reduction of chemical properties of the coating film, and influence of light energy coating film quality, and achieve excellent moisture resistance and excellent cold and heat resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

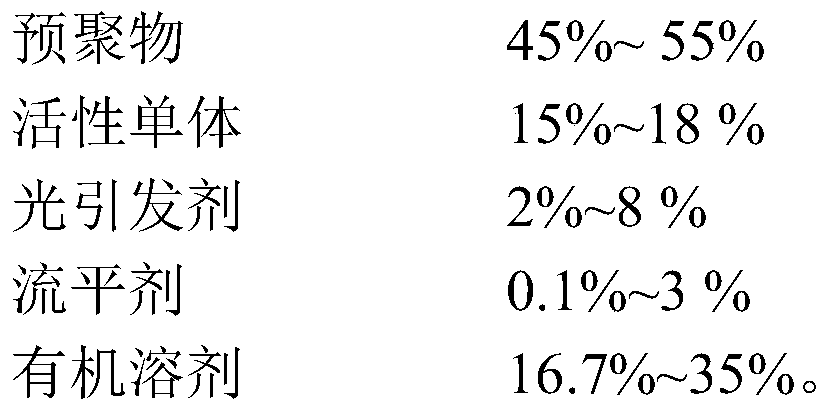

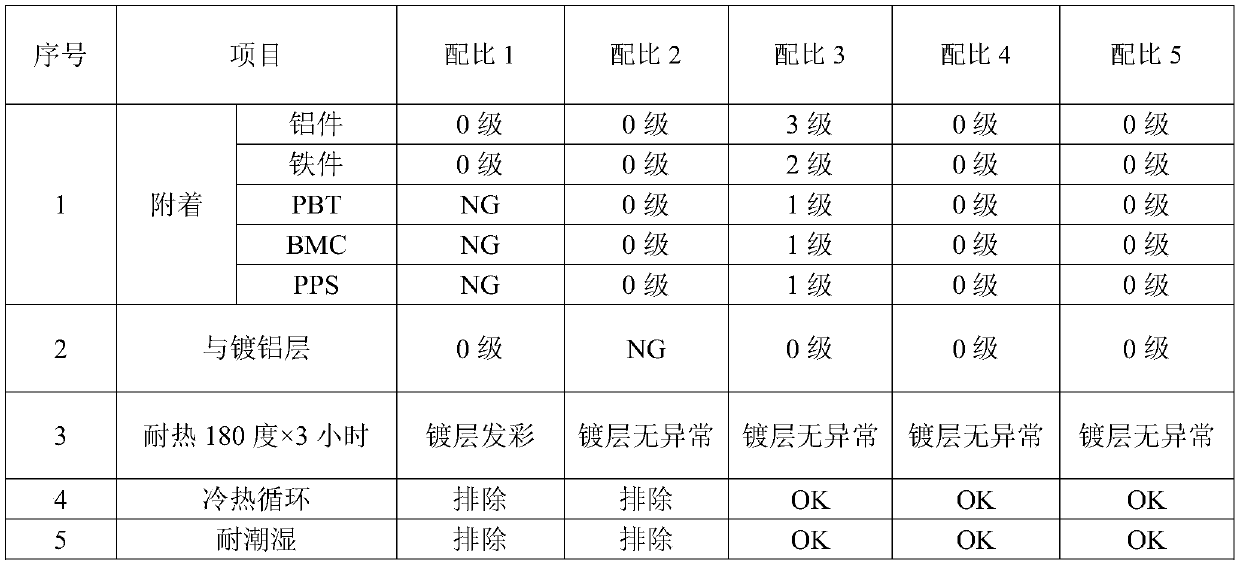

[0024] a) block ultraviolet rays, and use yellow light for illumination; b) add 2% 2,4,6-trimethylbenzoyl-diphenylphosphine oxide to 9.9% ethyl acetate, 10% n-butyl acetate, 5% of methyl isobutyl ketone and 5% of the mixed organic solvent composed of butyl ester fully dissolved, stirring evenly; c) in the case of keeping stirring, sequentially add 10% of trimethylolpropane three Methacrylate (TMPTA) and 8% pentaerythritol tetraacrylate; 50% ER-5468H; 0.1% polydimethylsiloxane, and then stir evenly to complete the production of UV coating.

Embodiment 2

[0026] a) block ultraviolet rays, and use yellow light for illumination; b) add 8% of 2-hydroxyl-2-methyl-1-phenylacetone to 2% of ethyl acetate, 2% of n-butyl acetate, 5% of formazan Fully dissolved in a mixed organic solvent composed of isobutyl ketone and 1% sec-butyl ester, and stirred evenly; c) While keeping stirring, add 10% trimethylolpropane trimethacrylate in sequence (TMPTA), 3% of 1,6-hexanediol diacrylate, 4% of dipentaerythritol hexaacrylate and 8% of pentaerythritol tetraacrylate; 30% of ER-5468H, 20% of KG-991 and 5 % of RA-3091; 2% of polyether polyester modified organosiloxane, and then stir evenly to complete the production of UV coatings.

Embodiment 3

[0028] a) block ultraviolet rays, and use yellow light for illumination; b) mix 3% of 2,4,6-trimethylbenzoyl-diphenylphosphine oxide, 1% of diphenylethanone and 2% of 2-hydroxy- 2-Methyl-1-phenylacetone is added to 7.7% of ethyl acetate, 6% of methyl isobutyl ketone and 3% of the mixed organic solvent composed of butyl ester fully dissolved, stirred evenly; c) in While keeping stirring, add 5% trimethylolpropane trimethacrylate (TMPTA) and 5% bornyl acrylate; 20% ER-5468H, 30% KG-991 and 15% RA-3091; 1% polyether polyester modified organosiloxane and 1.3% alkyl modified organosiloxane, and then stir evenly to complete the production of UV coating.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com