Concrete laitance enhancer and preparation method and application thereof

A technology of reinforcement and concrete, applied in the direction of coating, etc., can solve the problems of low heat resistance and low adhesion between layers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

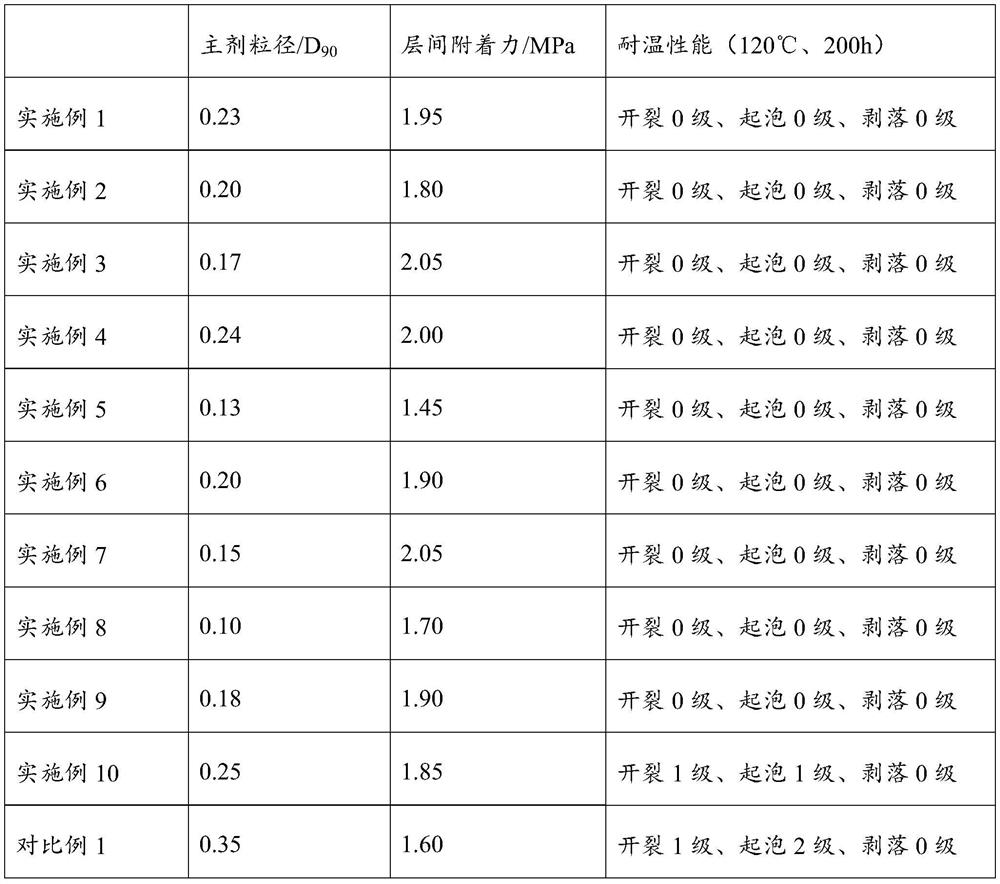

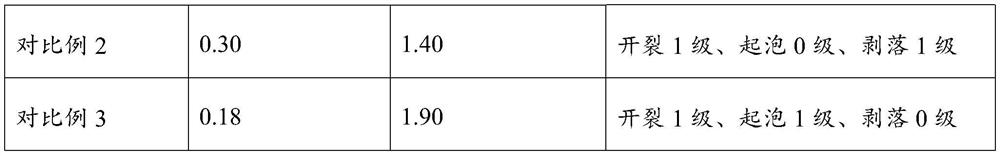

Examples

Embodiment 1

[0039] This embodiment provides a preparation method of concrete reinforcement, the specific preparation method is as follows:

[0040] Preparation of silanol monomers: add 100g of ethanol / water / ammonia (mass ratio 30 / 70 / 0.1) to a reactor equipped with stirring, thermocouple and dripping device, raise the temperature to 55°C, and start to drop 30g of vinyl Trimethoxysilane. Control the material addition rate to complete the addition within 3 hours, and control the temperature to 60°C. After the dropwise addition, continue to keep warm at 60°C for 3.5 hours to obtain the silanol sol, which is the silanol monomer.

[0041] Mix 100g of silicone acrylic graft copolymer (RS-996KD, MFT22°C), 10g of silanol monomer, 20g of epoxy silane monomer γ-(2,3-glycidoxy)propyltrimethoxysilane with Mix with 65g of water, and condense at 62°C for 1.5h to obtain the main ingredient;

[0042] 77g of main ingredient and 23g of curing agent (Beckocure EH623W) were packaged separately in proportio...

Embodiment 2

[0044] This embodiment provides a preparation method of concrete reinforcement, the specific preparation method is as follows:

[0045]Preparation of silanol monomers: Add 100g of ethanol / water / ammonia (mass ratio 30 / 70 / 0.1) to a reactor equipped with a stirring, thermocouple and dripping device, raise the temperature to 60°C, and start to drop 25 vinyl Trimethoxysilane. Control the material addition rate in 3.5 hours, and control the temperature at 65°C. After the dropwise addition, continue to keep warm at 65°C for 3.5h to obtain silanol sol.

[0046] Mix 100g of silicone acrylic graft copolymer (RS-996KD, MFT22°C), 15g of silanol monomer, 25g of epoxysilane monomer γ-(2,3-glycidyloxy)propyltrimethoxysilane with Mix 55g of water, and condense at 60°C for 2 hours to obtain the main ingredient;

[0047] 78g of main ingredient and 22g of curing agent (Beckocure EH623W) were packaged separately in proportion to obtain the concrete laitance reinforcement.

Embodiment 3

[0049] This embodiment provides a preparation method of concrete reinforcement, the specific preparation method is as follows:

[0050] Preparation of silanol monomers: add 100g of ethanol / water / ammonia (mass ratio 30 / 70 / 0.1) to a reactor equipped with stirring, thermocouple and dripping device, raise the temperature to 55°C, and start to drop 30g of vinyl Trimethoxysilane. Control the material addition rate to complete the addition within 3 hours, and control the temperature to 60°C. After the dropwise addition, continue to keep warm at 60°C for 4 hours to obtain silanol sol.

[0051] 100g of silicone acrylic graft copolymer (RS-996KD, MFT22°C), 5g of silanol monomer, 30g of epoxy silane monomer γ-(2,3-glycidoxy)propyltrimethoxysilane and Mix with 70g of water, and condense at 50°C for 2 hours to obtain the main ingredient;

[0052] 75g of main ingredient and 25g of curing agent (Beckocure EH623W) were packaged separately in proportion to obtain the concrete laitance reinf...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| adhesivity | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com