Graphene oxide-based redox system initiator and preparation and use method thereof

A technology of graphene and initiator, applied in the field of redox system initiator and preparation, which can solve the problems of poor performance, low product conversion rate, high strength without combining graphene oxide, high elastic modulus and high toughness, etc., and achieve reduction Polymerization reaction temperature, increase product conversion rate, and solve the effects of dispersion problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

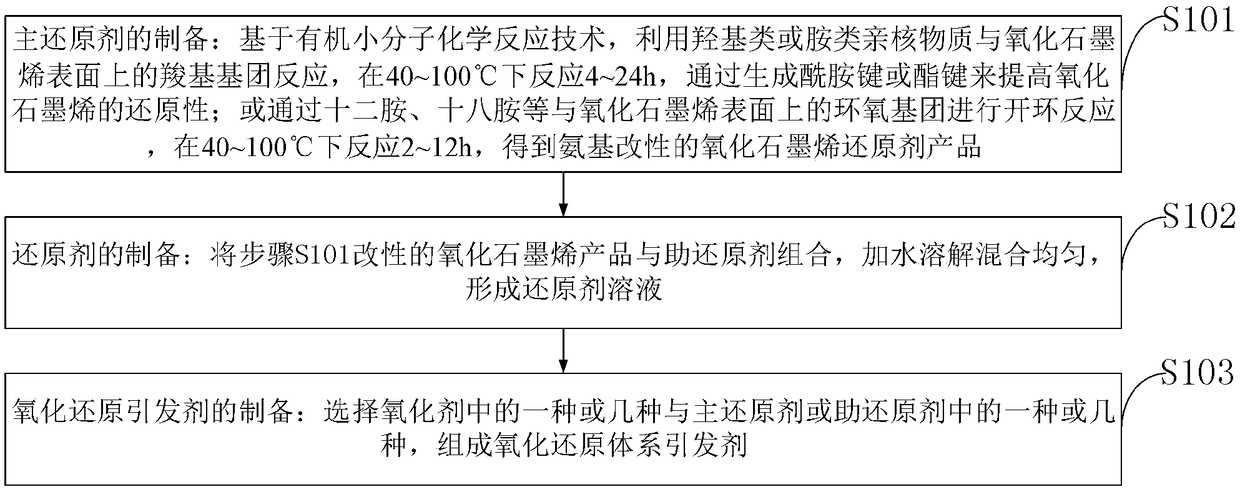

[0041] figure 1 The preparation method of the redox system initiator based on graphene oxide provided by the embodiments of the present invention comprises:

[0042] S101: Preparation of the main reducing agent: Based on organic small molecule chemical reaction technology, use hydroxyl or amine nucleophiles to react with carboxyl groups on the surface of graphene oxide, react at 40-100°C for 4-24h, and generate amide bond or ester bond to improve the reducibility of graphene oxide; or carry out ring-opening reaction with epoxy groups on the surface of graphene oxide through dodecylamine, octadecylamine, etc., and react at 40-100°C for 2-12h , to obtain an amino-modified graphene oxide reducing agent product.

[0043] S102: Preparation of reducing agent: combine the graphene oxide product modified in step S101 with a co-reducing agent, add water to dissolve and mix uniformly, and form a reducing agent solution.

[0044] S103: Preparation of a redox initiator: select one or mo...

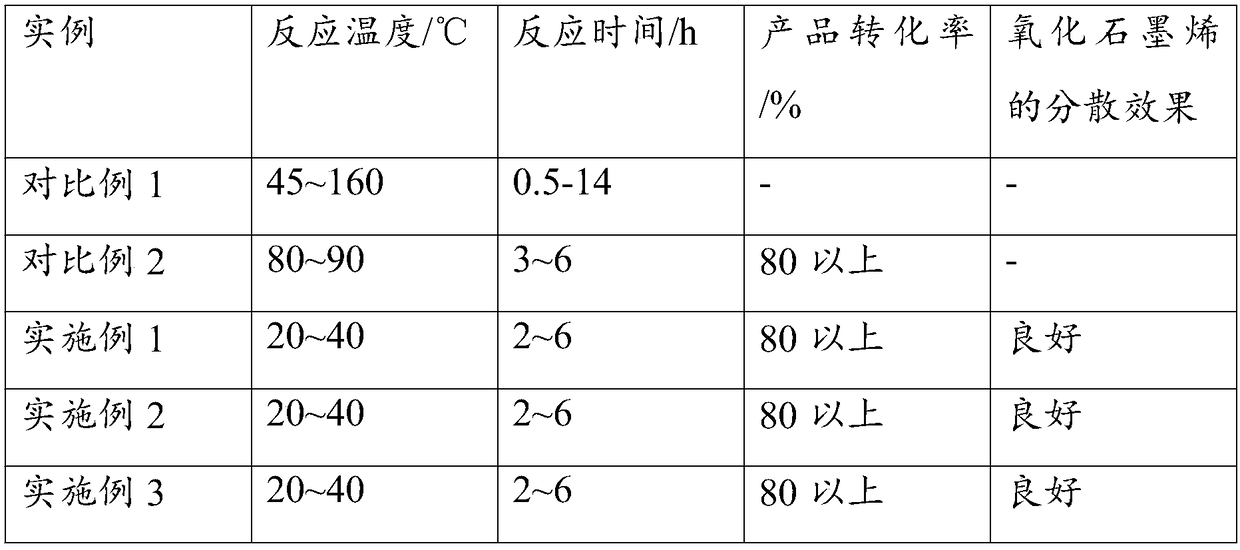

Embodiment 1

[0047]The graphene oxide-based redox initiator provided in the embodiment of the present invention is mainly composed of 50 parts of oxidizing agent, 40 parts of main reducing agent and 50-100 parts of water in terms of mass fraction.

Embodiment 2

[0049] The graphene oxide-based redox initiator provided in the embodiment of the present invention mainly consists of 60 parts of oxidizing agent, 50 parts of main reducing agent, 10 parts of co-reducing agent and 100 parts of water in terms of mass fraction.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com