Novel polycarboxylate based superplasticizer and preparation method thereof

A technology of polycarboxylate and water reducer, applied in the field of concrete admixture, can solve the problems of enlargement, uneven dispersion, unfavorable engineering application, etc., and achieve the effect of simple process, low cost, and solution to dispersion problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

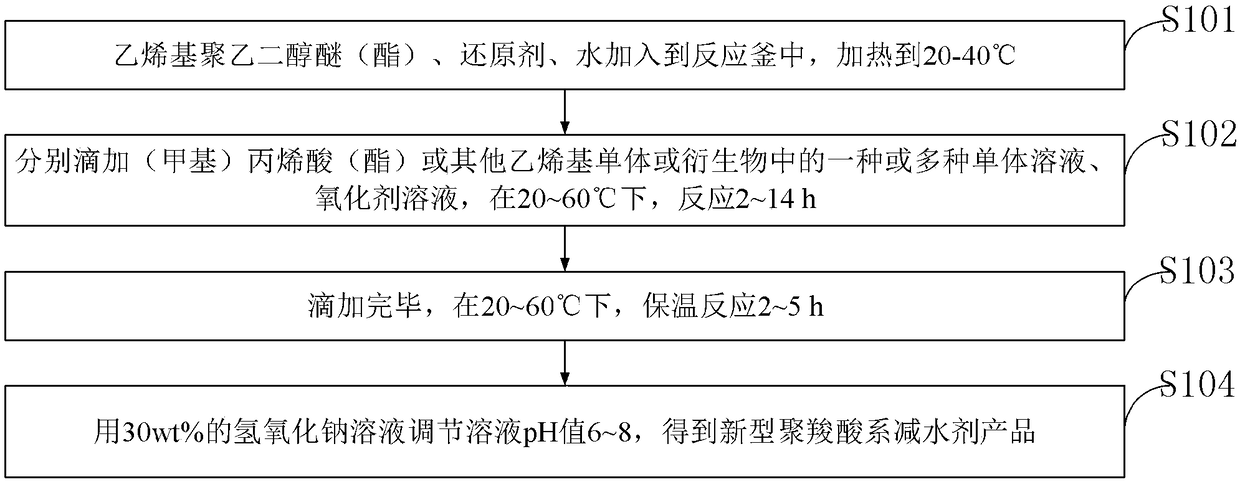

[0028] like figure 1 As shown, the preparation method of the polycarboxylate water reducer provided by the embodiment of the present invention includes:

[0029] S101: Add vinyl polyglycol ether (ester), reducing agent, and water into the reaction kettle, and heat to 20-40°C;

[0030] S102: Add (meth)acrylic acid (ester) or one or more monomer solutions and oxidant solutions in other vinyl monomers or derivatives dropwise, and react at 20-60°C for 2-14 hours;

[0031] S103: After the dropwise addition is completed, keep the reaction at 20-60°C for 2-5 hours;

[0032] S104: Use 30wt% sodium hydroxide solution to adjust the pH value of the solution to 6-8 to obtain a new polycarboxylate water reducer product.

[0033] The vinyl monomers provided by the embodiments of the present invention are mainly two or more of (meth)acrylic acid (ester), vinyl polyglycol ether (ester), other vinyl monomers and derivatives;

[0034] The initiator provided in the embodiment of the present i...

Embodiment 1

[0038] The components and mass ratios of the polycarboxylate water reducer provided in the embodiment of the present invention are: vinyl polyglycol ether (ester) 30, (meth)acrylic acid (ester) or other vinyl monomers and derivatives 5 parts of substance, 0.1 part of oxidant, 0.05 part of reducing agent and 40 parts of water.

Embodiment 2

[0040] The components and mass ratios of the polycarboxylate water reducer provided in the embodiment of the present invention are: 40 parts of vinyl polyglycol ether (ester), (meth)acrylic acid (ester) or other vinyl monomers and 15 parts of derivatives, 2 parts of oxidizing agent, 2 parts of reducing agent and 60 parts of water.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com