Test method of glass fiber reservation length of glass fiber reinforced hot-moulding composite

A test method and composite material technology are applied in the field of testing the glass fiber retention length in glass fiber reinforced thermoplastic composite materials to achieve the effect of high accuracy, high accuracy and avoiding the influence of human subjective factors.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

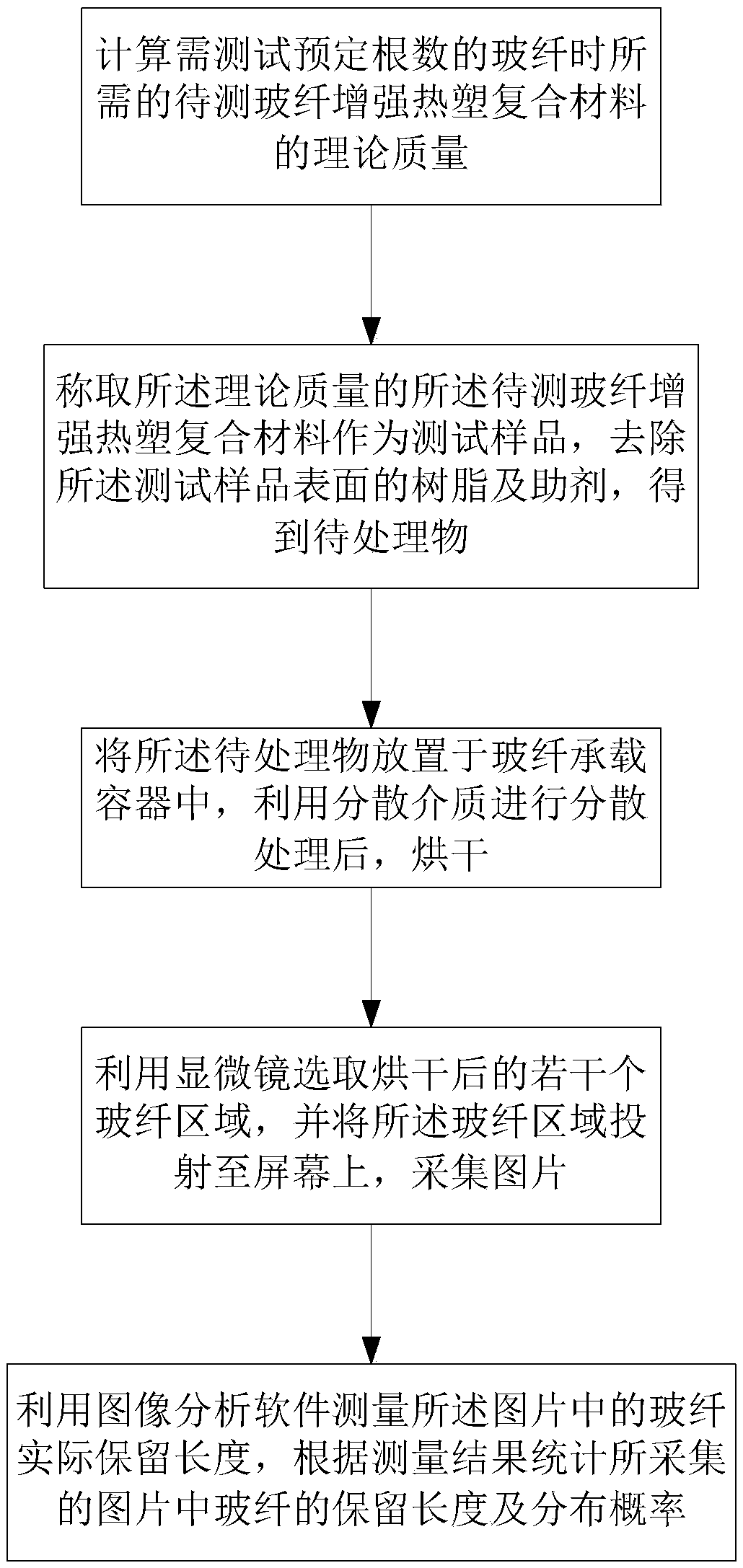

Method used

Image

Examples

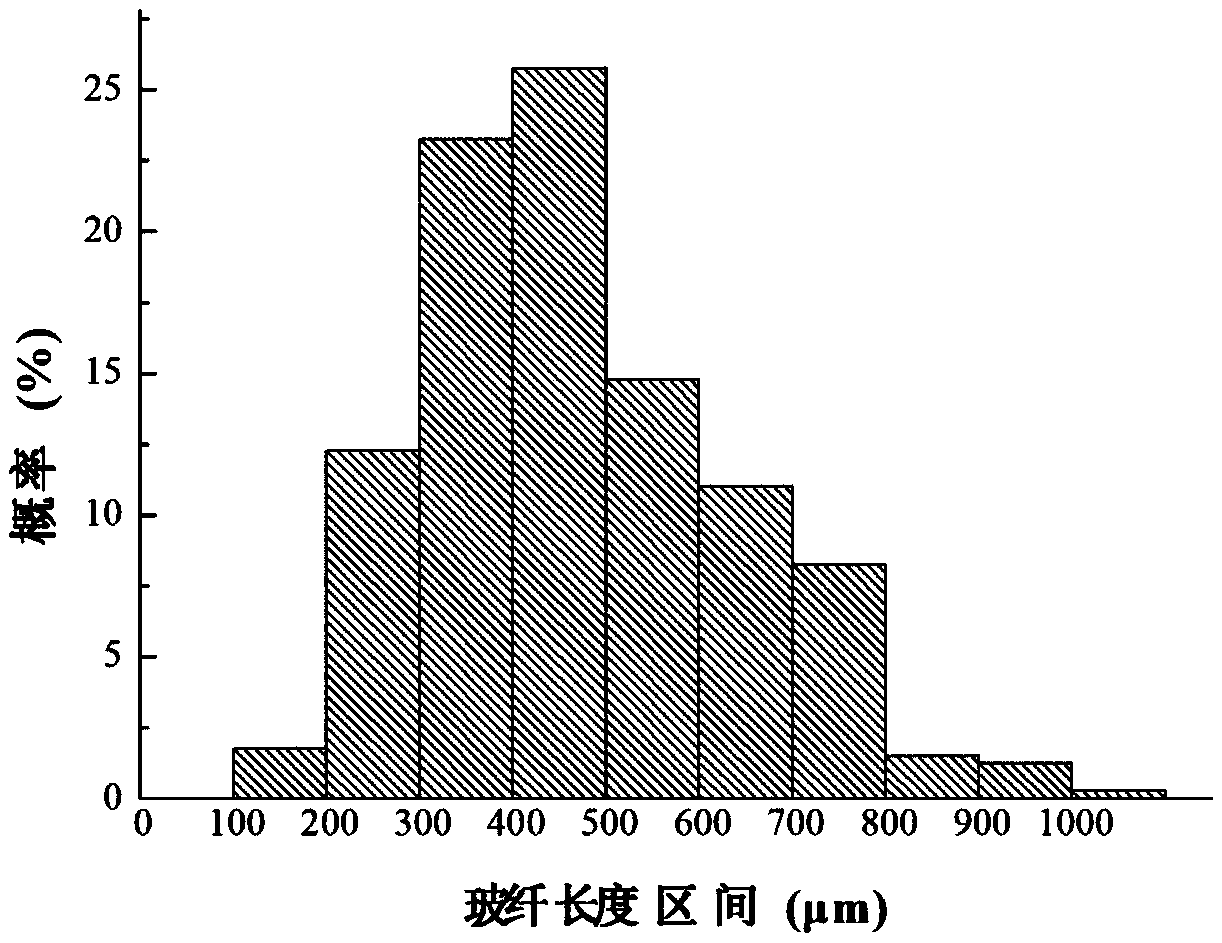

Embodiment 1

[0064] For glass fiber weight percentage content of 20%, glass fiber density of 2.60g / cm 3 1. For a chopped glass fiber reinforced thermoplastic resin composite material with a single fiber diameter of 10 μm (that is, its theoretical glass fiber length is 1 mm), test its glass fiber retention length:

[0065] Preparation before the test: Prepare the glass fiber reinforced thermoplastic resin composite material to be tested, a polarizing microscope with a projection system, a muffle furnace and a crucible for burning the glass fiber composite material, and a 60mm transparent glass fiber that can disperse and carry the glass fiber Petri dish, ethanol reagent for dispersion;

[0066] Calculation: Calculate the theoretical mass of the above-mentioned glass fiber reinforced thermoplastic composite material required to test 10,000 pieces of the above-mentioned chopped glass fiber composite material as 10mg;

[0067] Resin and additive removal: Weigh 10 mg of the glass fiber reinfor...

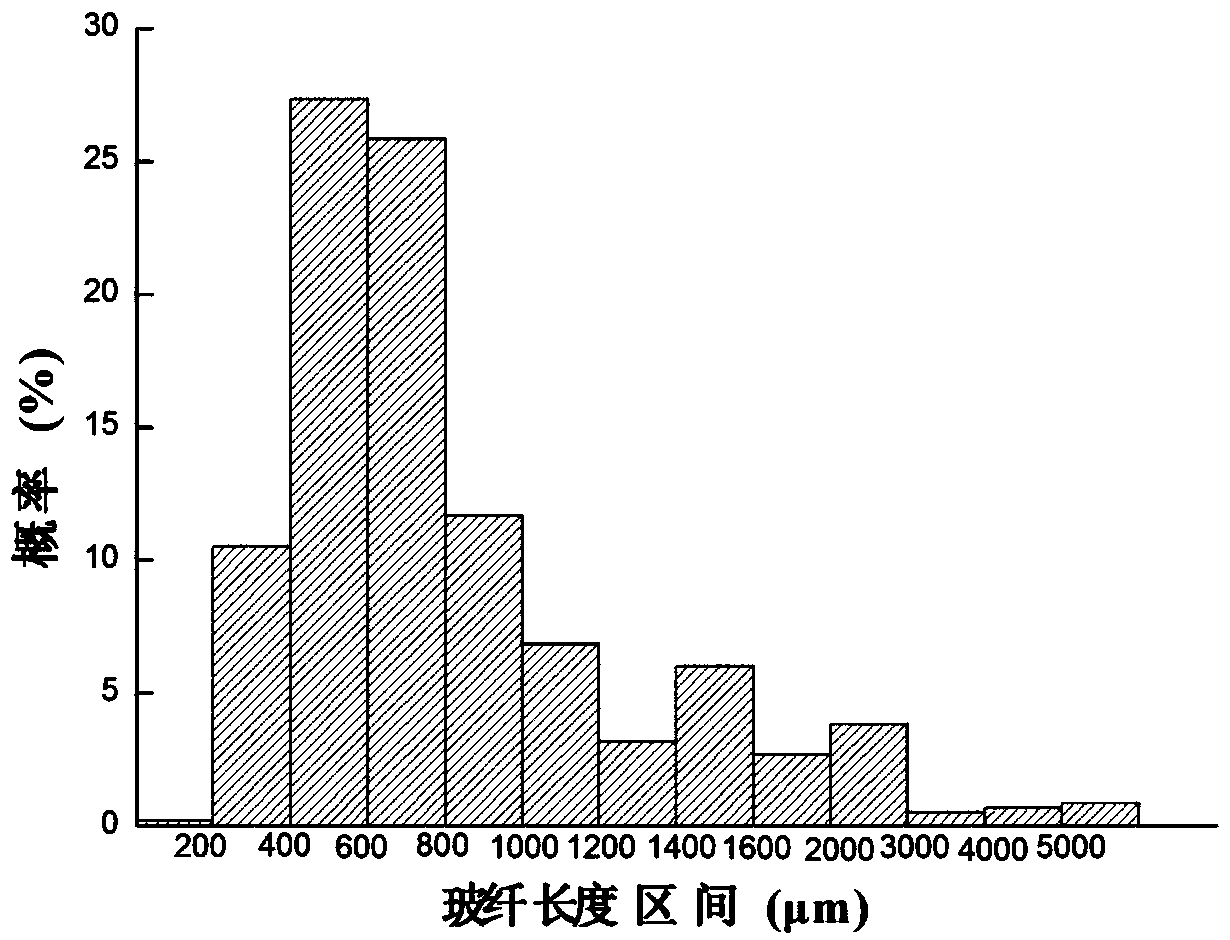

Embodiment 2

[0078] For glass fiber weight percentage content of 20%, glass fiber density of 2.60g / cm 3 1. For a long glass fiber reinforced thermoplastic resin composite material with a single fiber diameter of 17 μm (that is, the theoretical length of the glass fiber is 2 mm), test its glass fiber retention length:

[0079]Preparation before the test: Prepare the glass fiber reinforced thermoplastic resin composite material to be tested, a polarizing microscope with a projection system, a muffle furnace and a crucible for burning the glass fiber composite material, and a 60mm transparent glass fiber that can disperse and carry the glass fiber Petri dishes, ethanol reagents for dispersion;

[0080] Calculation: Calculate the theoretical mass of the above-mentioned glass fiber reinforced thermoplastic composite material required to test 10,000 pieces of the above-mentioned chopped glass fiber composite material to be 40 mg;

[0081] Resin and additive removal: Weigh 40 mg of the glass fib...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Single fiber diameter | aaaaa | aaaaa |

| Single fiber diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com