A hafnium-tantalum-silicon ternary composite ceramic precursor, carbon/hafnium-tantalum-carbon solid solution-silicon carbide ceramic matrix composite material and preparation method thereof

A technology of composite ceramics and precursors, applied in the field of composite materials, can solve the problems of difficult hafnium-tantalum-carbon solid solution dispersion of silicon carbide, unsolved hafnium-tantalum-carbon solid solution dispersion, impregnated fiber prefabrication, etc., to achieve easy industrial implementation , Excellent oxidation resistance, excellent ablation resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

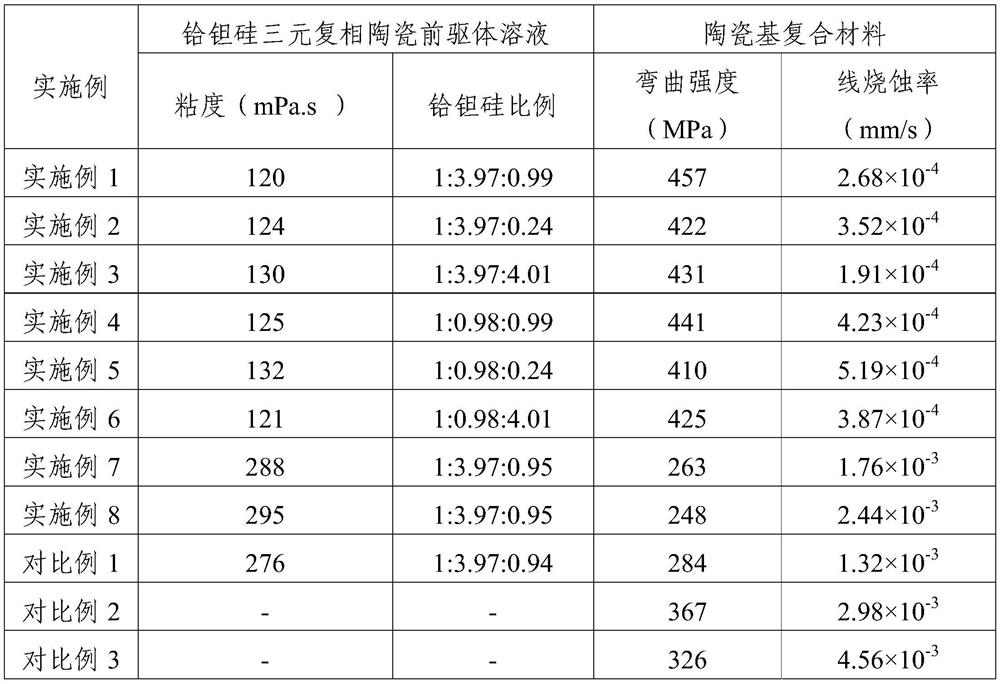

Examples

preparation example Construction

[0031] In a second aspect, the present invention provides a method for preparing the hafnium-tantalum-silicon ternary composite ceramic precursor described in the first aspect of the present invention, the method comprising the following steps:

[0032] (1) Mix pentavalent tantalum salt, tetravalent hafnium salt and small molecule alcohol evenly to obtain a mixture, then place the mixture in an ice bath at 0°C and add a catalyst for co-hydrolysis reaction to obtain hafnium tantalum alkoxide Solution; in the present invention, the addition of the catalyst can accelerate the reaction speed of the pentavalent tantalum salt, tetravalent hafnium salt and small molecule alcohol;

[0033] (2) adding the ligand to the hafnium-tantalum alkoxide solution obtained in step (1) to carry out a polymerization reaction to obtain a hafnium-tantalum coordination copolymer resin; and

[0034] (3) Mix the hafnium-tantalum coordination copolymer resin, the polycarbosilane, and the carbon source pr...

Embodiment 1

[0055] A method for preparing a hafnium-tantalum-silicon ternary composite ceramic precursor, the specific steps of which are:

[0056] ① In molar parts, mix 1 part of hafnium tetrachloride, 4 parts of tantalum pentachloride and 5 parts of n-propanol, place in an ice-water bath at 0°C, and drop an appropriate amount of diethylamine (the dosage of diethylamine is 0.3% of the mass sum of the pentavalent tantalum salt and the tetravalent hafnium salt), reacted for 3 hours, then added 5 parts of acetylacetone, polymerized at 80°C for 4 hours, and distilled at atmospheric pressure for 5 hours to remove excess n-propanol to obtain hafnium-tantalum coordination copolymer resin.

[0057] ② In terms of molar parts, mix 1 part of the hafnium-tantalum coordination copolymer resin obtained in step ①, 1 part of polycarbosilane, 2 parts of allyl phenolic resin and 4 parts of xylene, stir mechanically for 6 hours, and let stand for 8 hours. hours, and filtered to obtain a uniform hafnium-ta...

Embodiment 2

[0061] A method for preparing a hafnium-tantalum-silicon ternary composite ceramic precursor, the specific steps of which are:

[0062] ① In molar parts, mix 1 part of hafnium tetrachloride, 4 parts of tantalum pentachloride and 5 parts of n-propanol, place in an ice-water bath at 0°C, and drop an appropriate amount of diethylamine (the dosage of diethylamine is 0.3% of the mass sum of the pentavalent tantalum salt and the tetravalent hafnium salt), reacted for 3 hours, then added 5 parts of acetylacetone, polymerized at 80°C for 4 hours, and distilled at atmospheric pressure for 5 hours to remove excess n-propanol to obtain hafnium-tantalum coordination copolymer resin.

[0063] ② In terms of molar parts, mix 4 parts of the hafnium-tantalum coordination copolymer resin obtained in step ①, 1 part of polycarbosilane, 5 parts of allyl phenolic resin and 7 parts of xylene, stir mechanically for 6 hours, and let stand for 8 hours. hours, and filtered to obtain a uniform hafnium-t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com