Preparation method of nanometer single ion conductor

A single-ion and conductor technology, applied in the field of preparation of nano-single-ion conductors, can solve the problems of difficulty in dispersion, easy agglomeration, and unsatisfactory product performance, and achieve the effect of convenient enhancement and modification.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

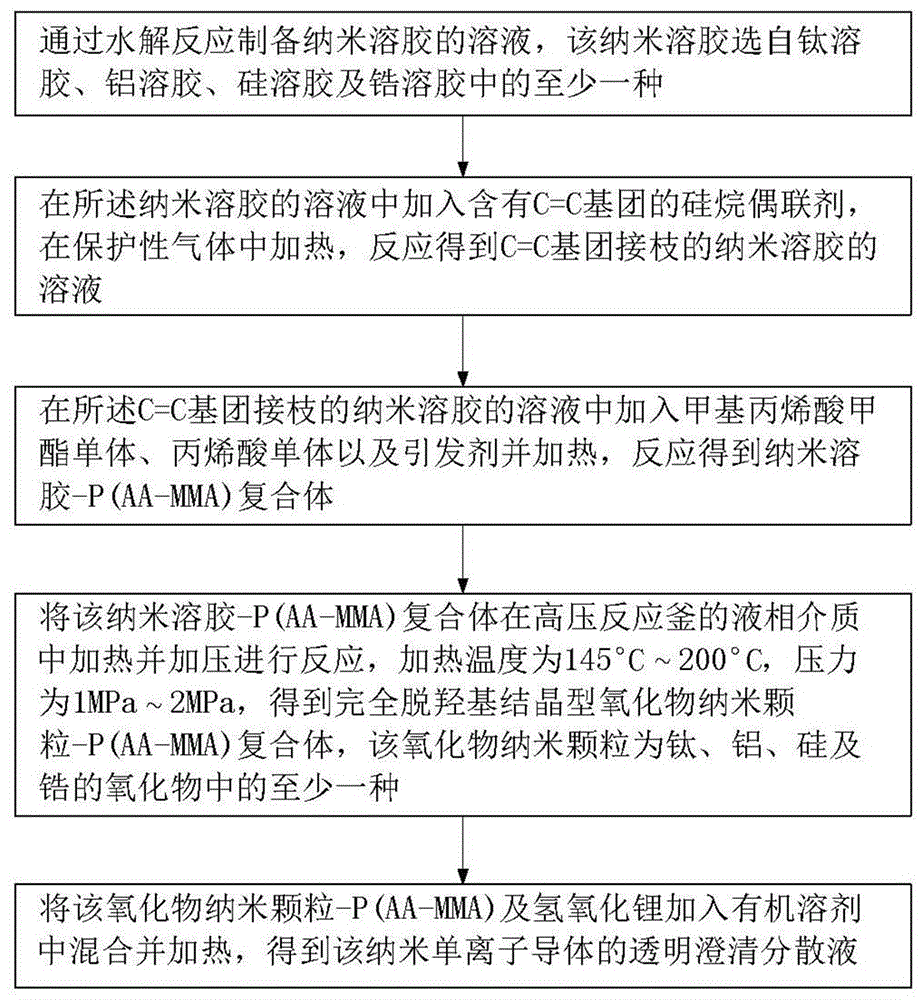

[0013] see figure 1 and figure 2 , an embodiment of the present invention provides a method for preparing a nanometer single ion conductor, which includes the following steps:

[0014] S1, preparing a solution of nano sol by hydrolysis reaction, the nano sol is selected from at least one of titanium sol, aluminum sol, silica sol and zirconium sol, specifically comprising the following steps:

[0015] S11, dissolving at least one of the compounds of titanium, aluminum, silicon and zirconium that can undergo hydrolysis reactions in an organic solvent to form a first solution;

[0016] S12, mixing water and an organic solvent to form a second solution; and

[0017] S13, mixing and heating the first solution and the second solution to form the nano-sol solution, and the step S12 or S13 further includes adjusting the pH value to 3-4 or 9-10 by adding acid or base;

[0018] S2, adding a silane coupling agent containing a C=C group to the solution of the nano-sol, heating in a pr...

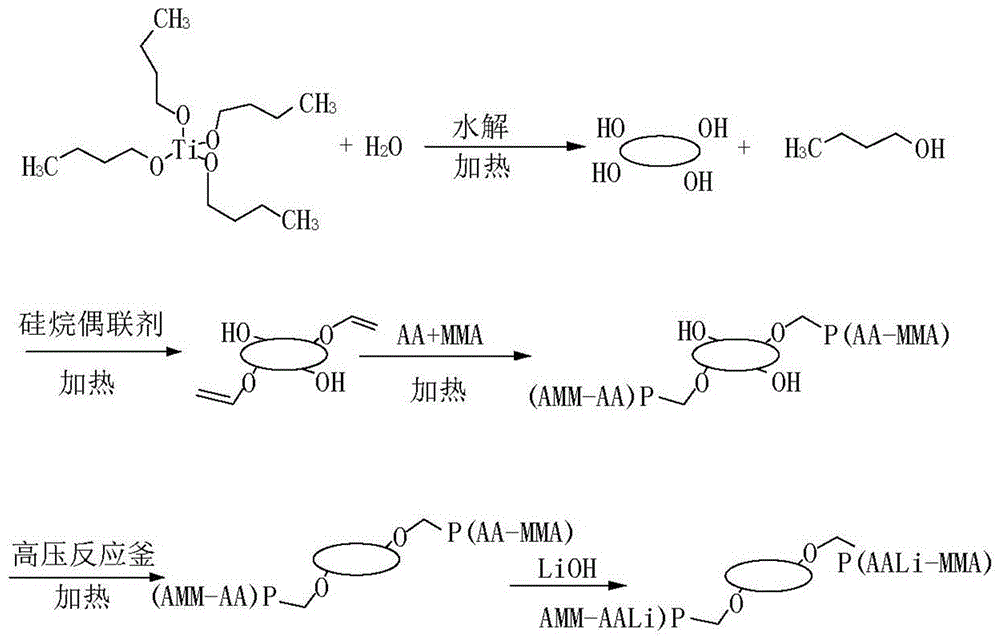

Embodiment 1

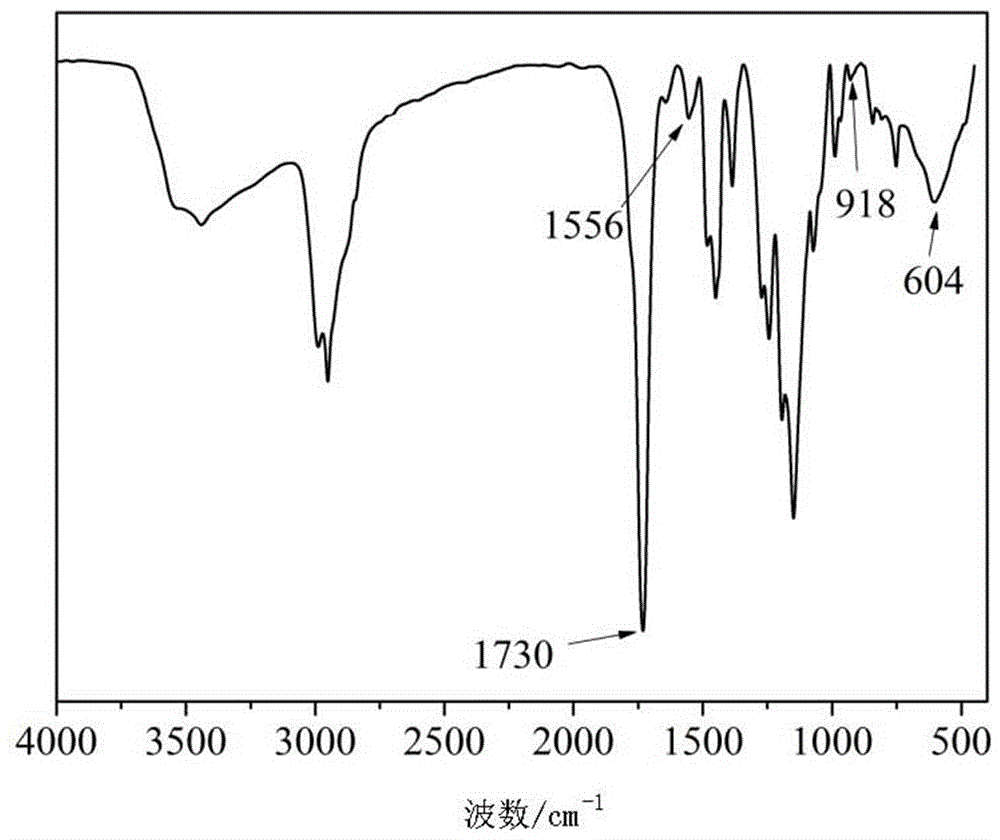

[0041] Mix 10 mL of tetrabutyl titanate with 50 mL of ethanol to form a first solution. Deionized water was mixed with 50 mL of ethanol to form a second solution. The molar ratio of deionized water to tetrabutyl titanate is 4:1. Slowly drop the second solution into the first solution for mixing, add concentrated nitric acid to adjust the pH to 3-4, stir and heat at 65°C for half an hour to obtain a titanium sol solution. Vinyltriethoxysilane was added to the titanium sol solution, and the temperature was raised to 80° C. for 1 hour under nitrogen protection to obtain a titanium sol solution grafted with C=C groups, adding MMA monomer and AA monomer, and Add the initiator benzoyl peroxide, and react at 80°C for 12 hours to obtain a solution of titanium dioxide nanosol-P(AA-MMA) complex. The solution of this titanium dioxide nano sol-P(AA-MMA) complex is placed in an autoclave, and heat-treated at 145° C. for 24 hours to obtain a complete dehydroxylation crystalline nano-TiO ...

Embodiment 2

[0043] The difference from Example 1 is only that tetrabutyl titanate is replaced by aluminum isopropoxide.

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com