A graphene microchip masterbatch for road asphalt modification and preparation method thereof

A kind of technology of graphene micro-sheet and master batch

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

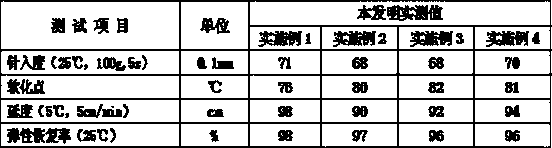

Examples

Embodiment 1

[0036] (1) Mix 500 parts by weight of expanded graphite powder and 40 parts by weight of asphalt emulsion evenly, and send them into the first stage of the double-stage co-rotating twin-screw extruder, set the screw temperature to 60-80°C, and the first stage of the screw machine The shearing section, the gel section, and the devolatilization section are set in sequence from the feed end to the discharge end; in the shear section, the asphalt emulsion peels the expanded graphite powder into graphene micro-sheets under the shearing action of the screw; in the gel section By introducing citric acid to control the pH value at 4-5, the asphalt emulsion is gelled, and the graphene microsheets are connected to form a network structure through the asphalt gelation; in the devolatilization section, the volatile matter is discharged and collected through the vacuum port; The asphalt emulsion described therein is obtained by grinding and dispersing isopropanol, petroleum asphalt, and imi...

Embodiment 2

[0040] (1) Mix 55 parts by weight of expanded graphite powder and 50 parts by weight of asphalt emulsion evenly, and send them into the first stage of the double-stage co-rotating three-screw machine, set the screw temperature to 60-80°C, and the first stage of the screw machine is composed of From the feed end to the discharge end, a shear section, a gel section, and a devolatilization section are arranged in sequence; in the shear section, the asphalt emulsion is exfoliated into graphene micro-sheets under the shearing action of the screw; in the gel section, by introducing The acid-base regulator controls the pH value at 5 to make the asphalt emulsion gel, forming a network structure connected by graphene microsheets; in the volatilization section, the volatile matter is discharged and collected through the vacuum port provided; the asphalt emulsion is made of It is obtained by grinding and dispersing isopropanol, synthetic asphalt, and imidazoline at a mass ratio of 10:3:0....

Embodiment 3

[0044] (1) Mix 60 parts by weight of expanded graphite powder and 50 parts by weight of asphalt emulsion evenly, and send them into the first stage of the two-stage screw machine, set the screw temperature at 60-80°C, and the first stage of the screw machine is from the feed end to the The discharge end is provided with a shear section, a gel section, and a devolatilization section in turn; in the shear section, the asphalt emulsion is exfoliated into graphene micro-sheets under the shearing action of the screw; in the gel section, the acid-base regulator is introduced Control the pH value at 4 to gel the asphalt emulsion, forming a network structure connected by graphene microsheets; in the devolatilization section, the volatile matter is discharged and collected through the vacuum port;

[0045] (2) The material obtained in step (1) is continuously sent to the second stage of the two-stage screw machine, and the screw temperature is set to 120°C. The second stage of the screw...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com