A kind of method of photocatalytic maleic anhydride grafted linen

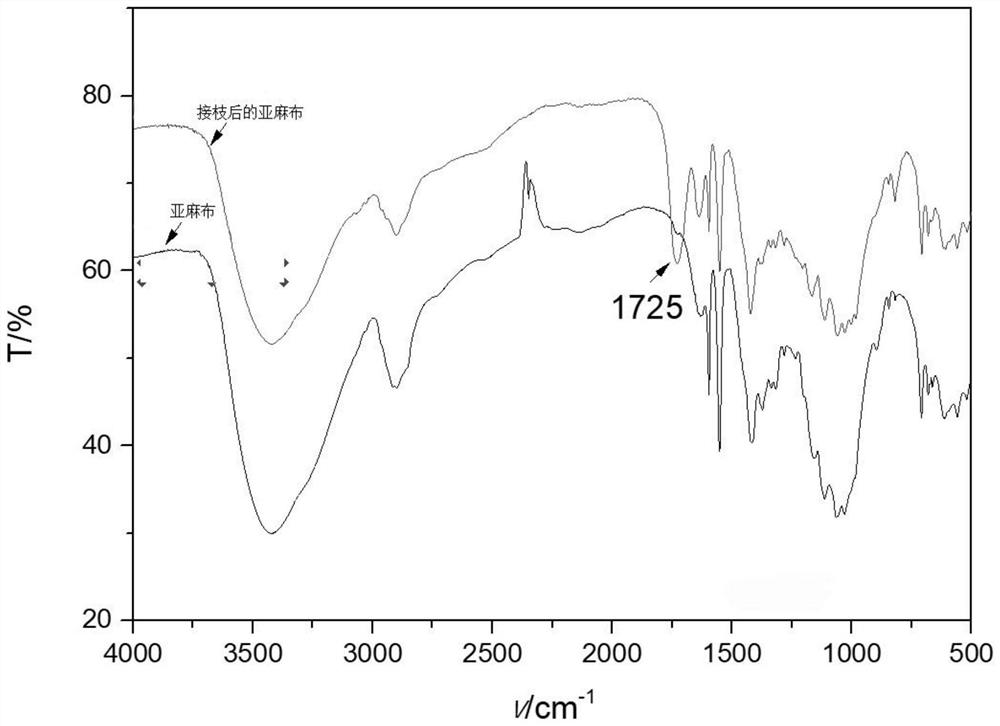

A technology of maleic anhydride and linen, which is used in fiber processing, textiles and papermaking, etc., to achieve high production efficiency, high grafting rate, and low environmental pollution.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

[0034] A method for photocatalyzed maleic anhydride grafted linen, is characterized in that: comprises the steps:

[0035] Step 1. Put the linen cloth in 16% sodium hydroxide aqueous solution for 30 seconds, swell it, take it out immediately, wash it with distilled water until neutral, put it in a vacuum drying oven, and dry it at 60°C for 90 minutes. Take out spare;

[0036] Step 2, prepare maleic anhydride (MAH) N,N-dimethylformamide solution (DMF), wherein, the mass concentration of maleic anhydride (MAH) is 40%, add photoinitiator 2,4,6-tri Tolyl-diphenylphosphine oxide (TPO), the quality of TPO is 2% of the MAH quality taken by weighing; the linen cloth is placed in the prepared DMF solution of MAH and soaked for 15min, then put into the ultraviolet light instrument , the power is 280w, the wavelength is 395nm, and the front and back sides of the linen are irradiated for 4 minutes;

[0037] Step 3: After the irradiation is completed, take out the linen cloth, wash it wi...

specific Embodiment approach 2

[0038] A method for photocatalyzed maleic anhydride grafted linen, is characterized in that: comprises the steps:

[0039] Step 1. Put the linen cloth in 16% sodium hydroxide aqueous solution for 30 seconds, swell it, take it out immediately, wash it with distilled water until neutral, put it in a vacuum drying oven, and dry it at 60°C for 90 minutes. Take out spare;

[0040] Step 2, prepare maleic anhydride (MAH) N,N-dimethylformamide solution (DMF), wherein, the mass concentration of maleic anhydride (MAH) is 50%, add photoinitiator 2,4,6-tri Tolyl-diphenylphosphine oxide (TPO), the quality of TPO is 2% of the MAH quality taken by weighing; the linen cloth is placed in the prepared DMF solution of MAH and soaked for 15min, then put into the ultraviolet light instrument Among them, the power is 80% of the maximum power (the maximum power is 280w, the wavelength is 395nm), and the front and back sides of the linen are irradiated for 2 minutes;

[0041] Step 3: After the irra...

specific Embodiment approach 3

[0042] A method for photocatalyzed maleic anhydride grafted linen, is characterized in that: comprises the steps:

[0043] Step 1. Put the linen cloth in 16% sodium hydroxide aqueous solution for 30 seconds, swell it, take it out immediately, wash it with distilled water until neutral, put it in a vacuum drying oven, and dry it at 60°C for 90 minutes. Take out spare;

[0044] Step 2, prepare maleic anhydride (MAH) N,N-dimethylformamide solution (DMF), wherein, the mass concentration of maleic anhydride (MAH) is 10%, add photoinitiator 2,4,6-tri Tolyl-diphenylphosphine oxide (TPO), the quality of TPO is 2% of the MAH quality taken by weighing; the linen cloth is placed in the prepared DMF solution of MAH and soaked for 15min, then put into the ultraviolet light instrument Among them, the power is selected as 40% of the maximum power (the maximum power is 280w, the wavelength is 395nm), and the front and back sides of the linen are irradiated for 3 minutes;

[0045] Step 3: Af...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com