Preparation method of polypropylene containing homoallylic end group

A technology of allyl end group and polypropylene, which is applied in the field of polypropylene preparation with high allyl end group, and can solve the problems of reducing polymer tacticity, low vinyl end group content, polymer stickiness, etc. problems, to achieve the effect of favorable reaction temperature control, high end group content, and reduced stickiness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-9

[0040] Treatment of methylalumoxane: Add 100mL of commercially available methylalumoxane solution into the reaction bottle, stir and vacuumize, at the same time slowly heat to 50°C, and continue vacuuming when all the liquid in the reaction bottle disappears After 8 hours, 5.8 g of a white powdery substance was obtained, and then 60 mL of toluene was added to form a colorless transparent solution for later use. 1 H NMR analysis had failed to detect the presence of trimethylaluminum.

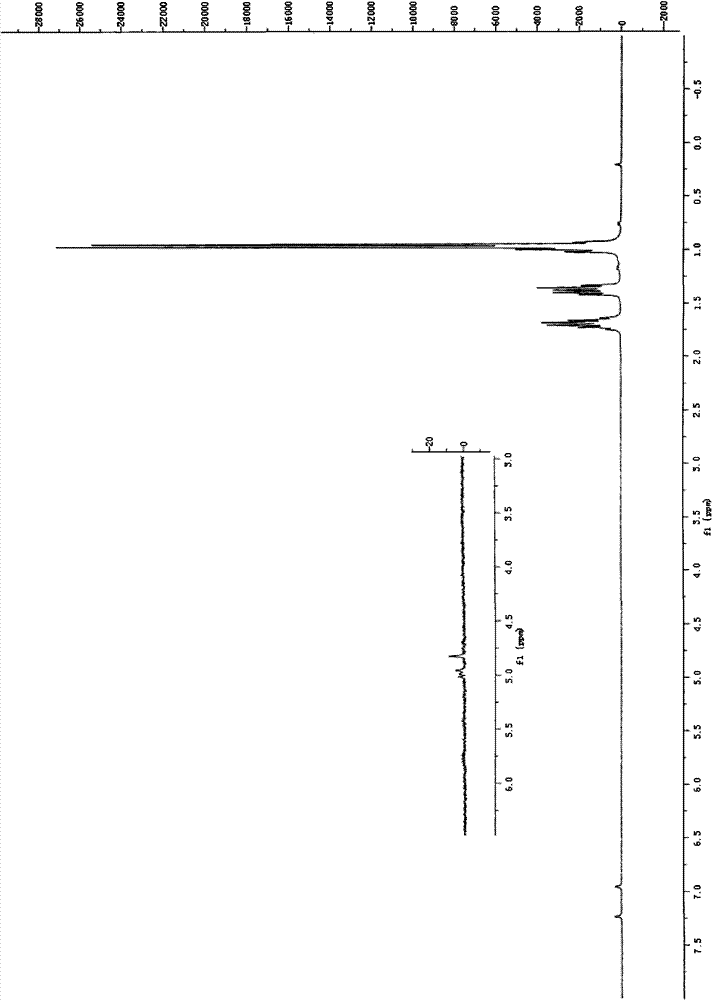

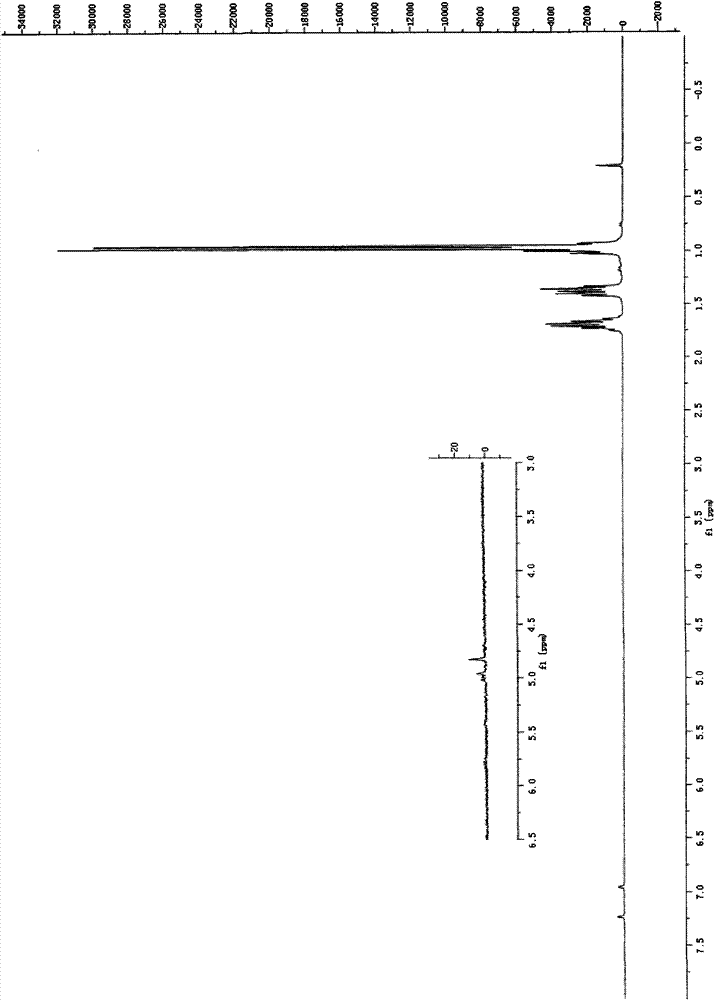

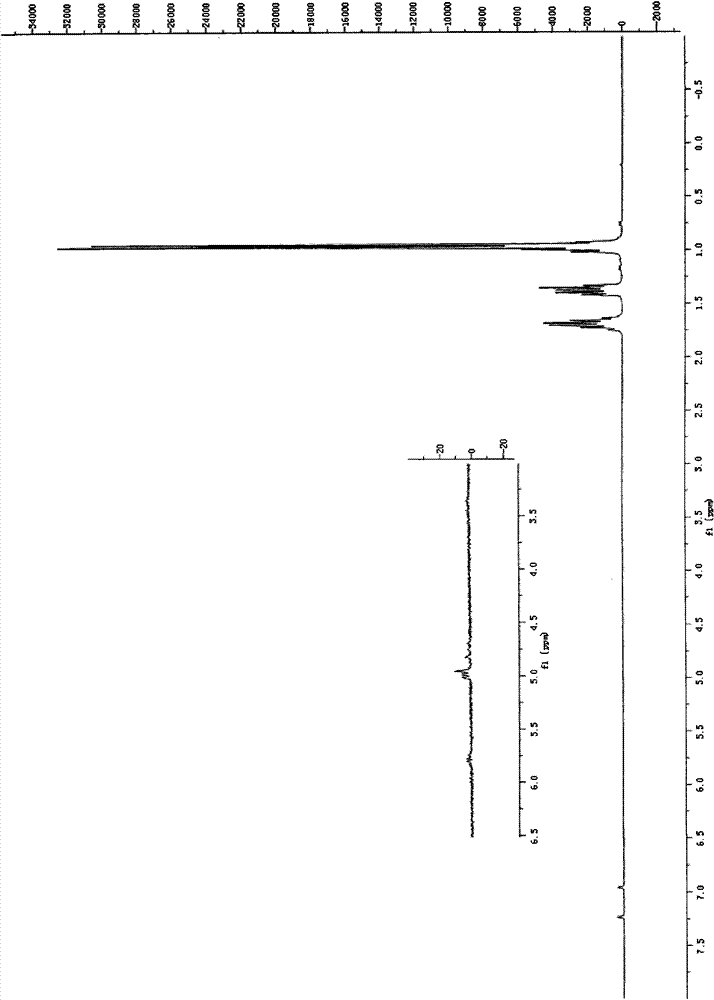

[0041] First purging the polymerization reactor with nitrogen, then replacing the nitrogen with propylene, setting to the desired polymerization temperature, adding 50 mL of toluene and metered methylaluminoxane cocatalyst to the polymerization reactor; stirring at the set temperature for 10 Minutes, keep the propylene pressure at 0.1MPa, add the required amount of metallocene catalyst, stir at the set temperature for 30 minutes, keep the propylene pressure constant during the polymerization proc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com