Preparation method for lithium ion secondary battery positive pole active substance lithium iron phosphate

A positive electrode active material, lithium iron phosphate technology, applied in battery electrodes, chemical instruments and methods, circuits, etc., can solve the problems of low battery capacity and poor cycle performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

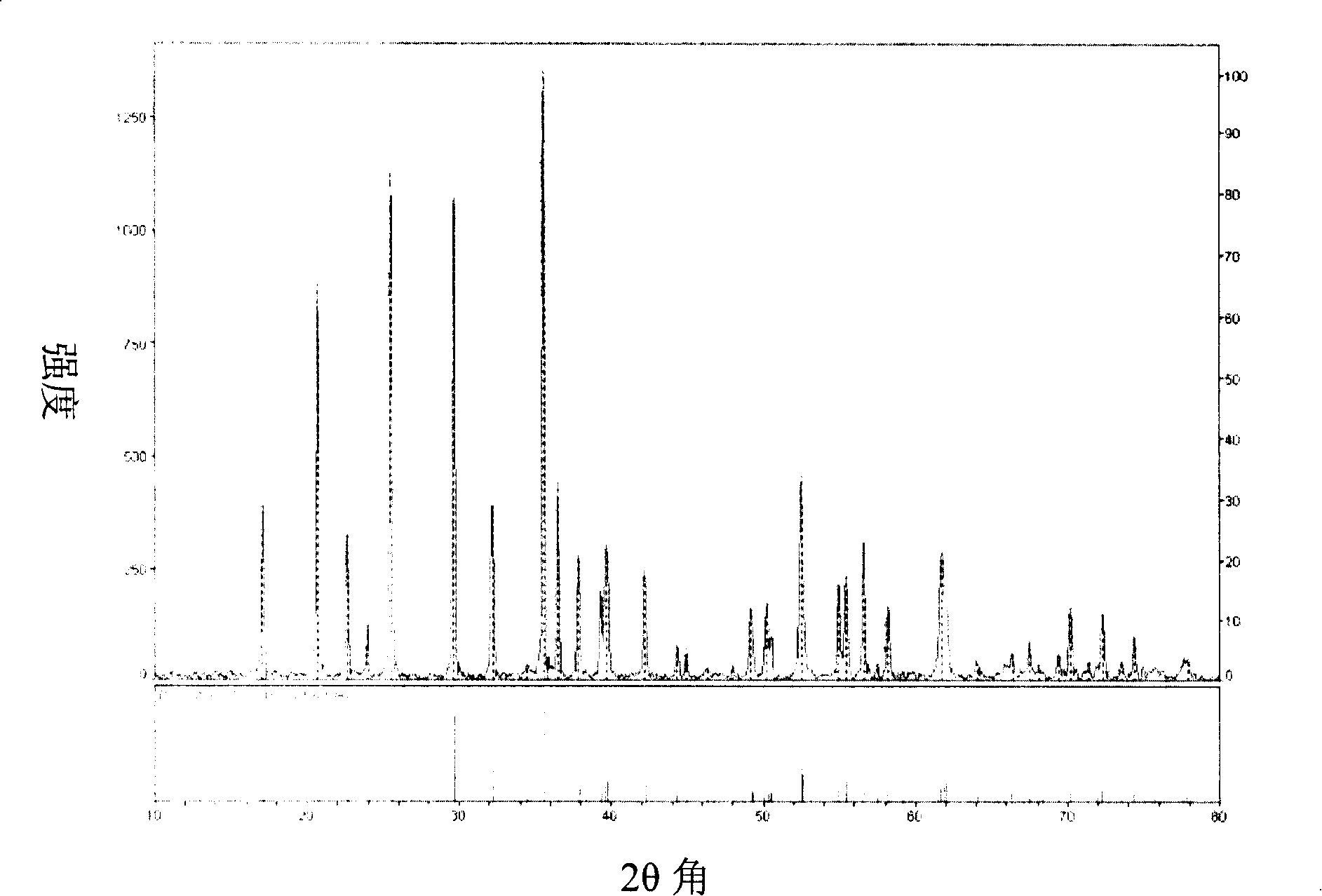

Image

Examples

Embodiment 1

[0029] This embodiment illustrates the preparation of the positive electrode active material lithium iron phosphate provided by the invention

[0030] (1) 46.92 grams of Li 2 CO 3 , 45.69 grams of FeC 2 o 4 2H 2 O, 152.93 g FePO 4 , 29.22 g NH 4 h 2 PO 4 Mix with glucose and 350 ml of absolute ethanol (Li:Fe:P molar ratio is 1:1:1), ball mill at 300 rpm for 20 hours, take it out, and dry at 70°C;

[0031] (2) Under the protection of argon gas with a flow rate of 10 liters / minute, the mixture in step (1) was heated to 700° C. for sintering at a constant temperature at a rate of 2° C. / minute for 18 hours, cooled to room temperature naturally, and then jet crushed. Obtain lithium iron phosphate lithium ion secondary battery cathode active material; the amount of glucose so that the carbon content in the generated lithium iron phosphate is 5% by weight. The tap density of the lithium ferrous phosphate is 1.28 g / ml, and the median particle diameter D 50 is 4.3 microns.

...

Embodiment 2

[0034] This embodiment illustrates the preparation of the positive electrode active material lithium iron phosphate provided by the invention

[0035] (1) 46.92 grams of Li 2 CO 3 , 18.29 g FeC 2 o 4 2H 2 O, 172.09 g FePO 4 , 14.61 g NH 4 h 2 PO 4 and glucose 3.81 g SnO 2 Mix it with 350 ml of absolute ethanol (the molar ratio of Li:Fe:Sn:P is 1:0.98:0.02:1), ball mill at 300 rpm for 20 hours, take it out, and dry it at 70°C;

[0036] (2) Under the protection of argon gas with a flow rate of 10 liters / min, the mixture in step (1) was heated to 750° C. for sintering at a constant temperature of 1° C. / min at a rate of 1° C. / min, and was sintered at a constant temperature for 15 hours, naturally cooled to room temperature, and then airflow pulverized, Obtain lithium iron phosphate lithium ion secondary battery cathode active material; the amount of glucose so that the carbon content in the generated lithium iron phosphate is 4% by weight. The tap density of the lithium ...

Embodiment 3

[0038] This embodiment illustrates the preparation of the positive electrode active material lithium iron phosphate provided by the invention

[0039] (1) 46.92 grams of Li 2 CO 3 , 21.24 g Fe 3 (PO 4 ) 2 ·8H 2 O, 172.09 g FePO 4 , 4.87 g NH 4 h 2 PO 4 Mix it with sucrose and 250 ml of absolute ethanol (Li:Fe:P molar ratio is 1:1:1), ball mill at 300 rpm for 20 hours, take it out, and dry it at 70°C;

[0040] (2) Under the protection of argon gas with a flow rate of 10 liters / min, the mixture in step (1) was heated to 800° C. for sintering at a constant temperature of 3° C. / min for 15 hours, cooled to room temperature naturally, and then jet crushed. Obtain lithium iron phosphate lithium ion secondary battery cathode active material; the amount of the sucrose so that the carbon content in the generated lithium iron phosphate is 3% by weight. The tap density of the lithium ferrous phosphate is 1.22 g / ml, and the median particle diameter D 50 is 4.2 microns.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com