Preparation method of nanometer lutecium oxide with large specific surface area

A technology with large specific surface area and lutetium oxide, applied in chemical instruments and methods, rare earth metal oxides/hydroxides, inorganic chemistry, etc. The effect of high brightness, uniform particle size and large specific surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

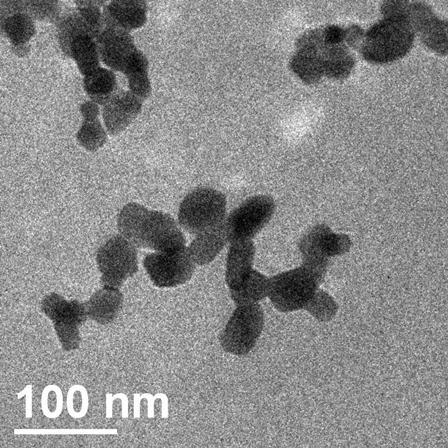

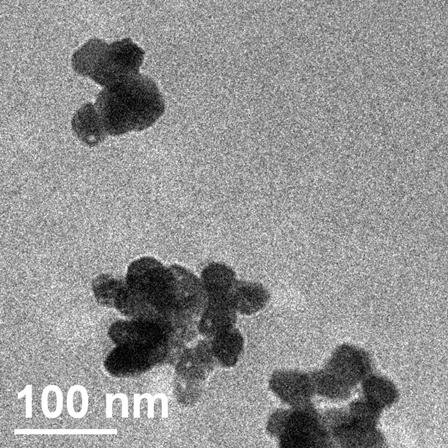

Image

Examples

Embodiment 1

[0010] Example 1: Precipitate 5KG of lutetium oxide. After calculation, add lutetium nitrate with a concentration of 0.4mol / L and a volume of 62.85L with pure water in the reaction kettle. The measured temperature is 17 degrees, and then the analytically pure carbonic acid is weighed. Sodium 4.26KG is prepared with pure water so that the concentration is 0.4mol / L, the volume is 100.56L, and the temperature is 15 degrees. Weigh 250 grams of PEG-20000 surfactant with a mass ratio of oxide of 5%, add 2.5L pure water , heated to dissolve it into a liquid, put PEG-20000 into lutetium nitrate, mix and stir for 15 minutes, then add sodium carbonate evenly, and the dropping time is 45 minutes, from which the dropping speed can be calculated as 2.23L / min. After the dropwise addition, add 100 grams of 2% sodium lauryl sulfate, heat and dissolve in 1L of pure water, add it to the above slurry, stir rapidly for 0.5 hours, and age for 2 hours , soak and wash in a suction filter barrel with...

Embodiment 2

[0011] Example 2: Precipitate 10KG of lutetium oxide. After calculation, add lutetium nitrate with a concentration of 0.5mol / L and a volume of 100.55L in the reaction kettle. The measured temperature is 25 degrees, and then the analytically pure carbonic acid is weighed. Sodium hydrogen 13.51KG is prepared with pure water so that the concentration is 0.6mol / L, the volume is 268.14L, and the temperature is 22 degrees. Weigh 1500 grams of PEG-20000 surfactant with a mass ratio of oxides of 15%, and add 15L of pure water , heated to dissolve it into a liquid, put PEG-20000 into lutetium nitrate and mix and stir for 30 minutes, then evenly add sodium bicarbonate dropwise, and the dropping time is 65 minutes, so it can be calculated that the dropping rate is 4.13L / min, by adjusting The speed device is used to control the flow rate and the rate of addition. After the dropwise addition, add 500 grams of 5% sodium dodecylbenzenesulfonate, put into 5L pure water and heat to dissolve, ad...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com