Preparation method of spinel type lithium manganate

A type of lithium manganate and spinel technology, applied in the field of preparation of spinel type lithium manganate, can solve the problems of long reaction time and unfavorable industrial promotion and application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

[0035] The embodiment of the preparation method of a spinel lithium manganate of the present invention comprises:

[0036] Load lithium salt and manganese salt on the surface of carbon particles;

[0037] The carbon particles loaded with lithium salt and manganese salt are calcined.

[0038] According to the present invention, the manganese salt may refer to any manganese salt known to those skilled in the art, preferably one or more of manganese nitrate, manganese chloride, manganese acetate, manganese sulfate or manganese carbonate, but not limited thereto. The lithium salt may refer to any lithium salt known to those skilled in the art, preferably one or more of lithium nitrate, lithium chloride, lithium acetate, lithium sulfate or lithium carbonate, but is not limited thereto. The carbon particles refer to simple carbon particles well known to those skilled in the art, and specific examples are preferably one or more of carbon black, activated carbon powder, coke powder, ...

Embodiment 1

[0052] Weigh 0.850g LiCl solid and put it into a 100ml beaker, then add about 3.616g of mass fraction of 50% Mn(NO 3 ) 2 solution, shake well to dissolve the LiCl solid to obtain a mixed solution;

[0053] Add 0.25g of acetylene black (provided by Tianjin Lihuajin Chemical Co., Ltd., with a particle size of 35nm to 40nm and quality standards in line with GB / T3782-2006) into the mixed solution, and stir evenly;

[0054] The beaker was placed in an electric constant temperature blast drying oven at 70°C for 4 hours;

[0055] After drying, the loaded LiCl and Mn(NO 3 ) 2 The acetylene black was transferred to a corundum crucible, and then the corundum crucible was put into an electric heating furnace, and fired under normal pressure in an air atmosphere, the firing temperature was 600° C., and the firing time was 1 h.

[0056] After roasting, cool the crucible to 50° C. in an electric heating furnace to take out the roasted product, add deionized water to dissolve, wash and f...

Embodiment 2

[0060] with LiNO 3 and MnCl 2 As a raw material, use water as a solvent to prepare 50ml of LiNO with a concentration of 0.02mol / L 3 and 0.01mol / L MnCl 2 mixed solution;

[0061] Add the acetylene carbon black of 0.5g to the mixed solution and then stir evenly, and the source of acetylene carbon black is the same as in Example 1;

[0062] Dry the solution at 65° C. for 4 hours in a blast drying oven to remove water;

[0063] After drying, the loaded LiNO 3 and MnCl 2 The acetylene black was transferred to the crucible, and then roasted under normal pressure in an electric heating furnace, the roasting temperature was 700°C, and the roasting time was 2h;

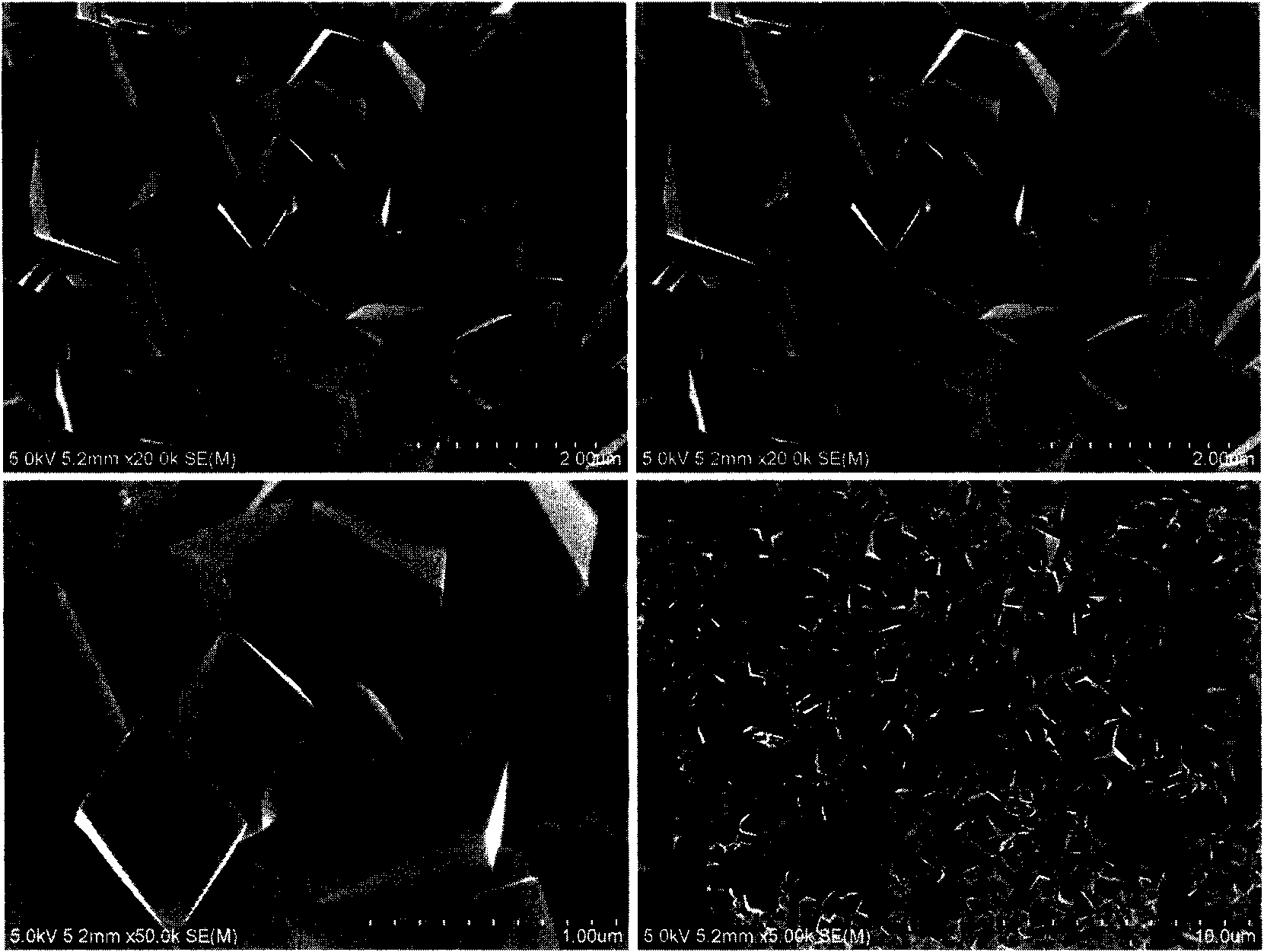

[0064] Cool the roasted product in the electric heating furnace to 50°C, take it out, add deionized water to dissolve, wash, filter, and dry at 70°C for 2 hours to obtain a black solid powder with a powder particle size of about 400nm;

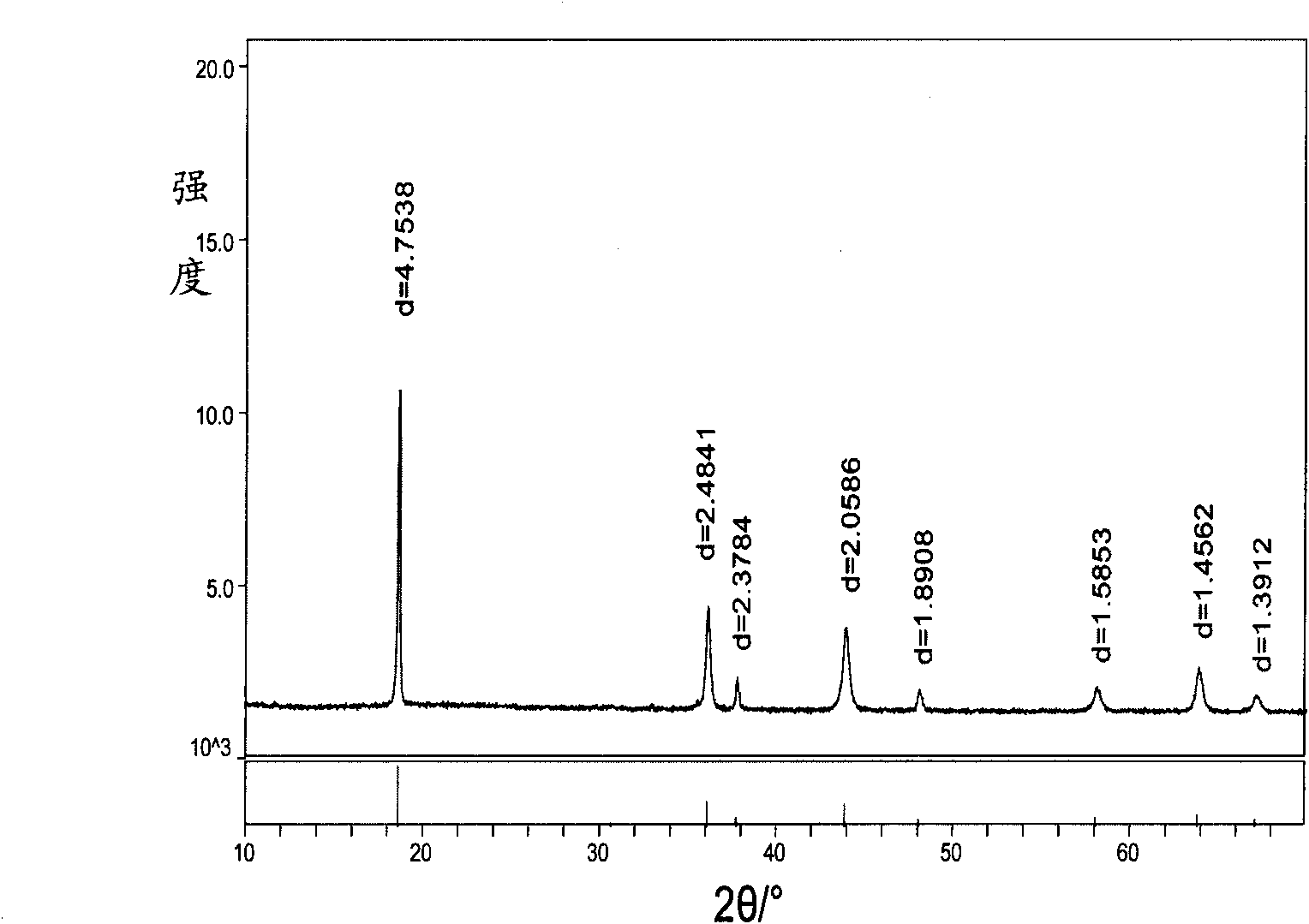

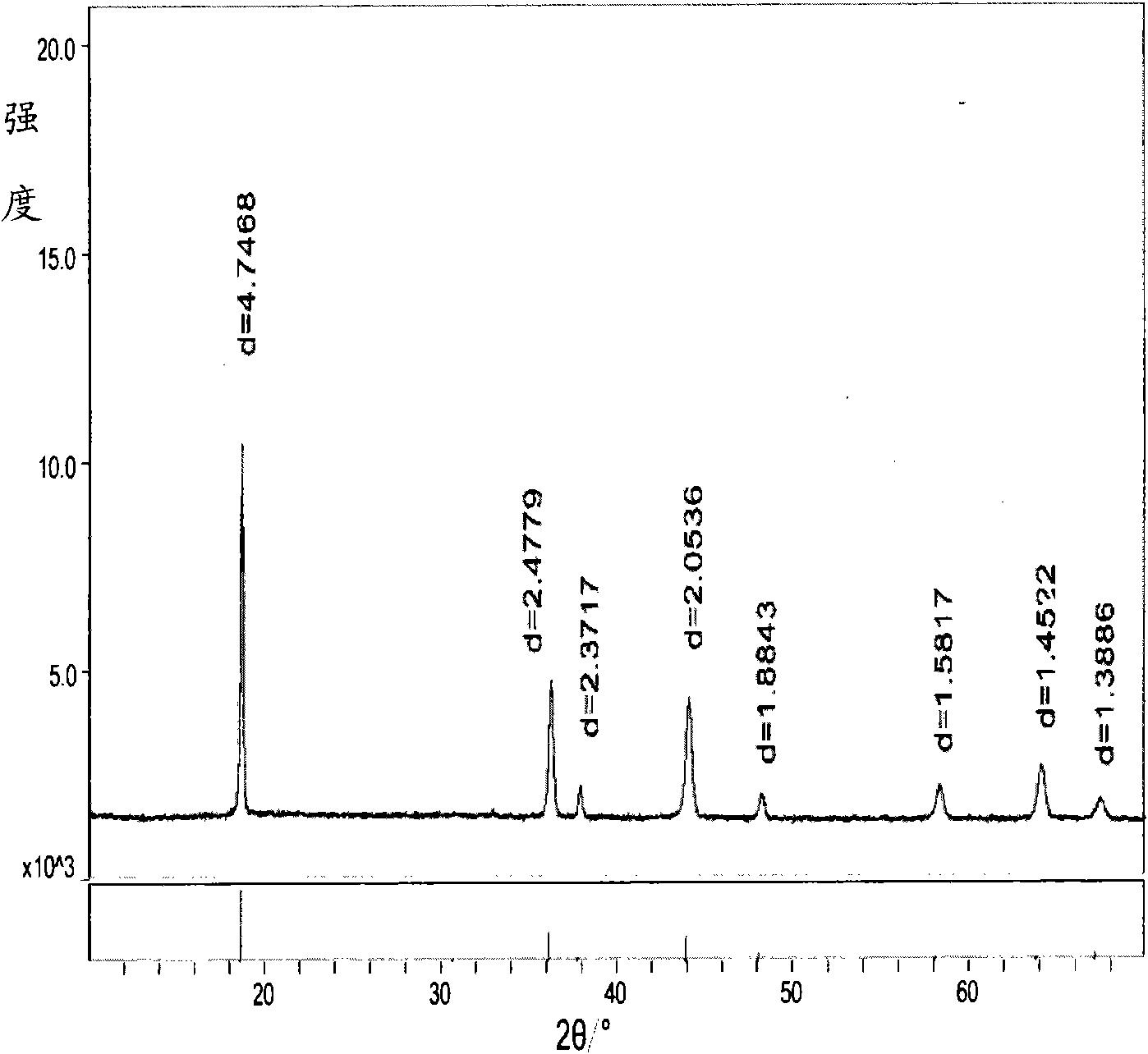

[0065] Get described black solid powder and measure with Phillips X'Pert Pro MPD X-...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Granularity | aaaaa | aaaaa |

| Powder size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com