Method for preparing high-softening point asphalt for coating natural graphite cathode material of lithium-ion battery

A high softening point asphalt and lithium-ion battery technology, which is applied in the chemical processing of tar pitch/petroleum pitch/natural pitch, battery electrodes, circuits, etc., can solve problems such as unmentioned uses, and achieve high discharge capacity, coulomb long-lasting effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

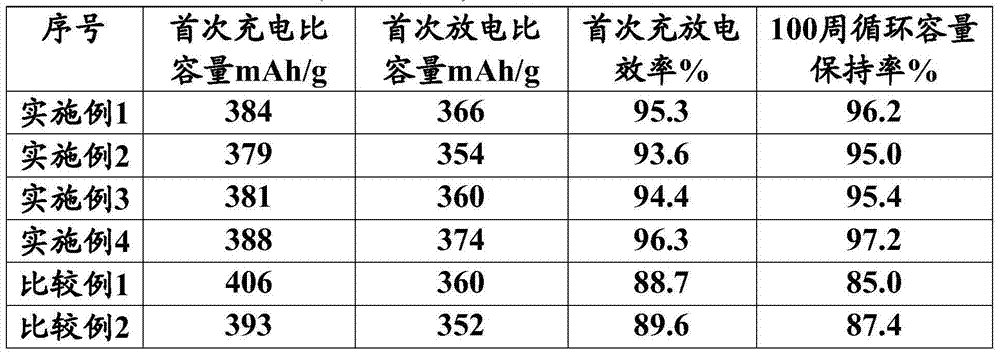

Examples

Embodiment 1

[0065] Send the medium-temperature bitumen raw material preheated to 100°C into the melting tank, and heat it to 200°C under the condition of vacuum negative pressure of 0.06MPa. The molten asphalt raw material is sent to the primary oxidation tank, and the air oxidant is continuously fed in from the bottom of the oxidation tank by an air compressor. The feed rate of asphalt raw material is 35Kg / h, and the feed rate of air oxidant is 10m 3 / h. Stir and oxidize at 280°C for 8 hours under a negative vacuum pressure of 0.08MPa. The oxidized product of the primary oxidation tank is sent to the secondary oxidation tank, and an air compressor is used to continuously feed the air oxidant from the bottom of the oxidation tank. The feed rate of asphalt raw material is 30Kg / h, and the feed rate of air oxidant is 15m 3 / h. Stir and oxidize at 300°C for 6 hours under a vacuum negative pressure of 0.08MPa. The oxidized product of the secondary oxidation tank is sent to the third oxida...

Embodiment 2

[0067] Send the medium-temperature bitumen raw material preheated to 120°C into the melting tank, and heat it to 220°C under a vacuum negative pressure of 0.06MPa. The molten asphalt raw material is sent to the primary oxidation tank, and the air oxidant is continuously fed in from the bottom of the oxidation tank by an air compressor. The feed rate of asphalt raw material is 55Kg / h, and the feed rate of air oxidant is 40m 3 / h. Stir and oxidize at 300°C for 5 hours under a negative vacuum pressure of 0.07MPa. The oxidized product of the primary oxidation tank is sent to the secondary oxidation tank, and an air compressor is used to continuously feed the air oxidant from the bottom of the oxidation tank. The feed rate of asphalt raw material is 45Kg / h, and the feed rate of air oxidant is 35m 3 / h. Stir and oxidize at 320°C for 6 hours under a vacuum negative pressure of 0.08MPa. The oxidized product of the secondary oxidation tank is sent to the third oxidation tank, and ...

Embodiment 3

[0069] Send the medium-temperature bitumen raw material preheated to 100°C into the melting tank, and heat it to 200°C under the condition of vacuum negative pressure of 0.06MPa. The molten asphalt raw material is sent to the primary oxidation tank, and the air oxidant is continuously fed in from the bottom of the oxidation tank by an air compressor. The feed rate of asphalt raw material is 45Kg / h, and the feed rate of air oxidant is 30m 3 / h. Stir and oxidize at 290°C for 5 hours under a negative vacuum pressure of 0.07MPa. The oxidized product of the primary oxidation tank is sent to the secondary oxidation tank, and an air compressor is used to continuously feed the air oxidant from the bottom of the oxidation tank. The feed rate of asphalt raw material is 35Kg / h, and the feed rate of air oxidizer is 28m 3 / h. Stir and oxidize at 310°C for 6 hours under a negative vacuum pressure of 0.06MPa. The oxidized product of the secondary oxidation tank is sent to the third oxida...

PUM

| Property | Measurement | Unit |

|---|---|---|

| softening point | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com