Making method for positive material LiFePO4 of poly-aniline coated lithium ion battery

A technology for lithium ion batteries and positive electrode materials, which is applied in the field of preparation of positive electrode materials for lithium ion batteries, can solve the problems of poor high temperature cycle performance, low capacity, unsafe overcharge and impossible to use large-capacity batteries, etc., and achieves long cycle life. , The effect of high discharge capacity and high specific capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

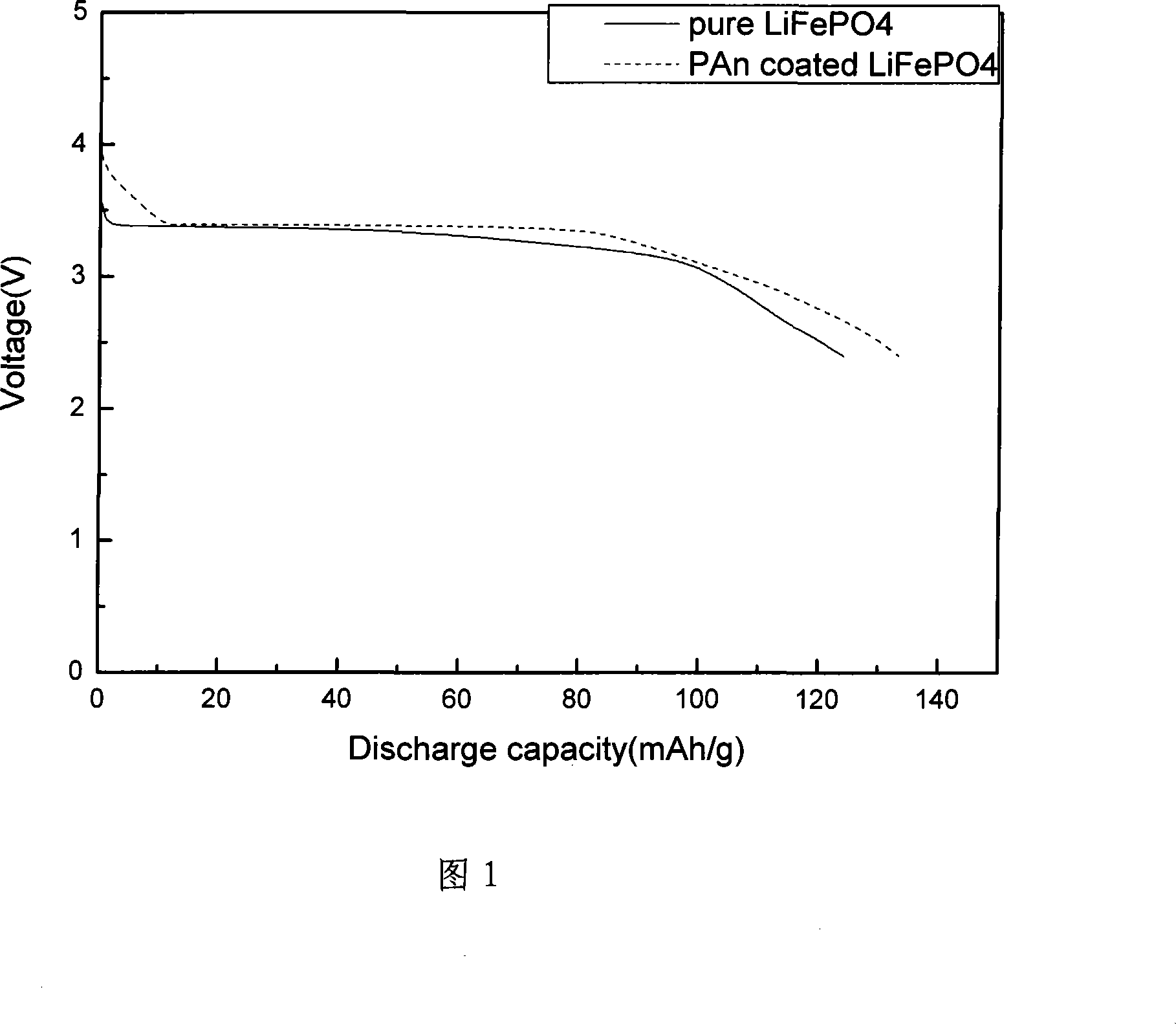

Embodiment 1

[0021] Accurately weigh Li according to the stoichiometric ratio 2 CO 3 , FeC 2 O 4 ·2H 2 O, (NH 4 ) 2 HPO 4 , Placed in a ball mill tank, the ratio of the size of the ball is 1:4, ball mill for 10 hours until the mixture is uniform. Then put the reactant in a quartz boat, put it into a tube furnace and heat up under the protection of argon. Firstly, the temperature is raised to 300°C at 5°C / min, the temperature is kept for 8h, and then it is naturally cooled to room temperature. After being taken out and ground, it is placed in a tube furnace again at 10°C / min to 700°C, kept for 20h and then naturally cooled to obtain LiFePO 4 . Weigh 4 grams of LiFePO 4 The powder was added to 0.1mol / L HCl and stirred for 30 minutes, 1mL aniline monomer was added and stirred for 30 minutes, 1.28g ammonium persulfate dissolved in 0.1mol / L HCl was added dropwise to the mixed solution, and the reaction was continued at room temperature. Stir under nitrogen protection. After reacting for 12 hours, s...

Embodiment 2

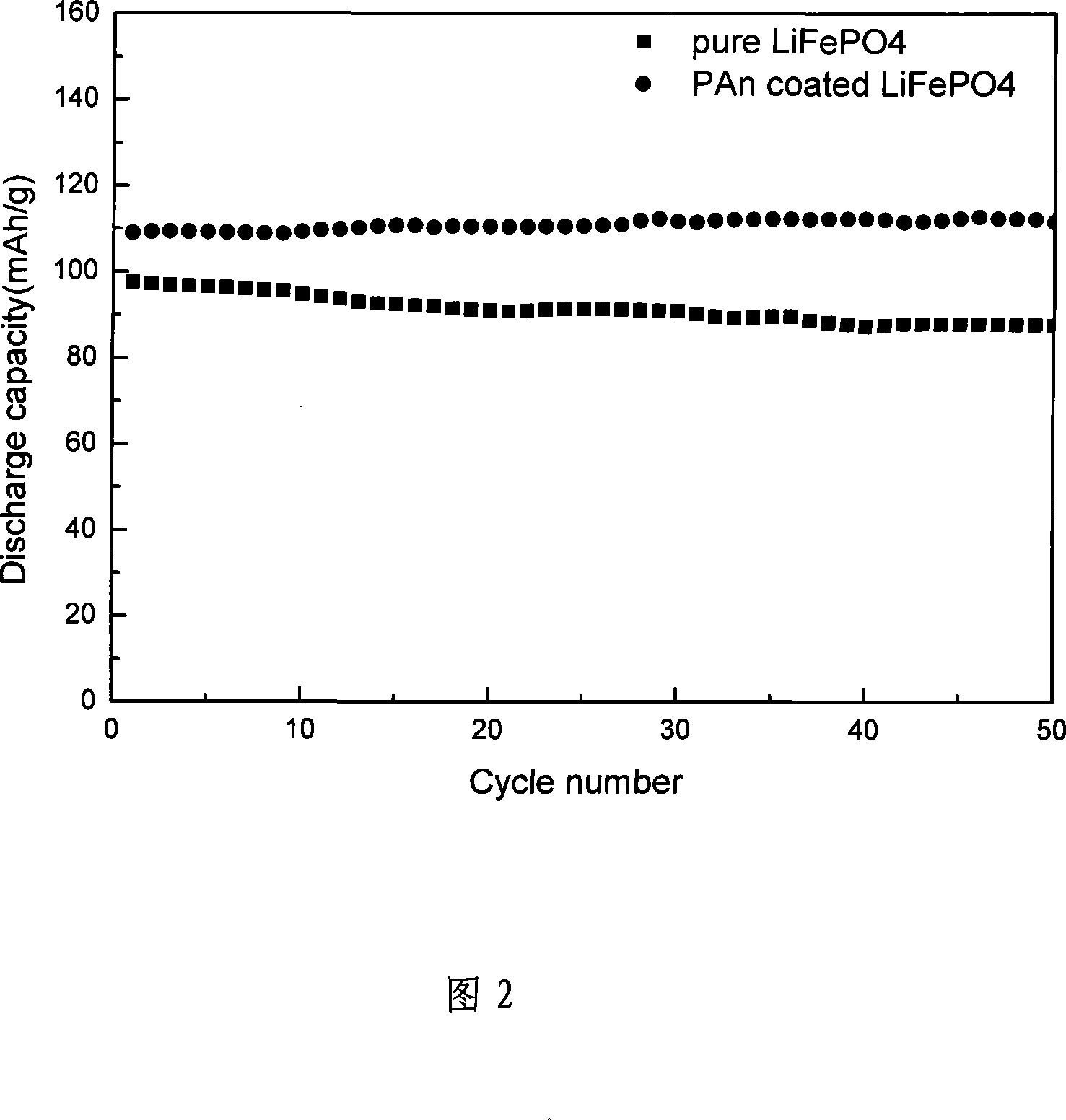

[0023] Accurately weigh Fe(NO 3 ) 3 ·9H 2 O, Li(CH 3 COO)·2H 2 O, dissolved in distilled water, add excess HOCH 2 COOH, will Fe 3+ Reduced to Fe 2+ , Then add the stoichiometric ratio of NH 4 H 2 PO 4 , Adjust the pH value to 8.5-9.2 with ammonia water, keep it at 60℃ for 24h to get the gel, heat the gel, protect it with argon, pre-decompose it at 300℃ for 3h, cool it and grind it into tablets. Calcined at 600℃ for 20h to obtain LiFePO 4 sample. Weigh 4 grams of LiFePO 4 The powder was added to 0.1mol / L HCl and stirred for 30 minutes, 1mL aniline monomer was added and stirred for 30 minutes, 1.28g ammonium persulfate dissolved in 0.1mol / L HCl was added dropwise to the monomer solution, and the reaction was carried out at room temperature. Stir continuously and protect with nitrogen. After reacting for 12 hours, stop stirring, filter and wash until the filtrate is colorless. Then, it was dried under vacuum at 60°C to obtain polyaniline-coated lithium iron phosphate. Using the lithi...

Embodiment 3

[0025] Prepare LiFePO under the same conditions as in Example 1. 4 . Weigh 4.5 grams of LiFePO 4The powder was added to 2mol / L HCl and stirred for 30 minutes, 0.5mL aniline monomer was added and stirred for 30 minutes, 0.64g ammonium persulfate dissolved in 2mol / L HCl was added dropwise to the monomer solution, and the reaction was continued at room temperature. Stir under nitrogen protection. After 6 hours of reaction, stop stirring, filter, and wash until the filtrate is colorless. Then, it was dried under vacuum at 60°C to obtain polyaniline-coated lithium iron phosphate. Using a lithium sheet as a negative electrode, the first specific discharge capacity of the polyaniline-coated lithium iron phosphate at room temperature was measured to be 133 mAh / g, and the capacity was still 110 mAh / g after 50 cycles of 1C.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com