Eccentric stirring ball mill

A stirring ball mill, eccentric technology, applied in mixers, mixers with rotating containers, dissolving and other directions, can solve the problems of unsatisfactory shape, large energy consumption and large volume of vertical mill products, and achieve significant energy-saving effect. The effect of reducing dust pollution and small size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

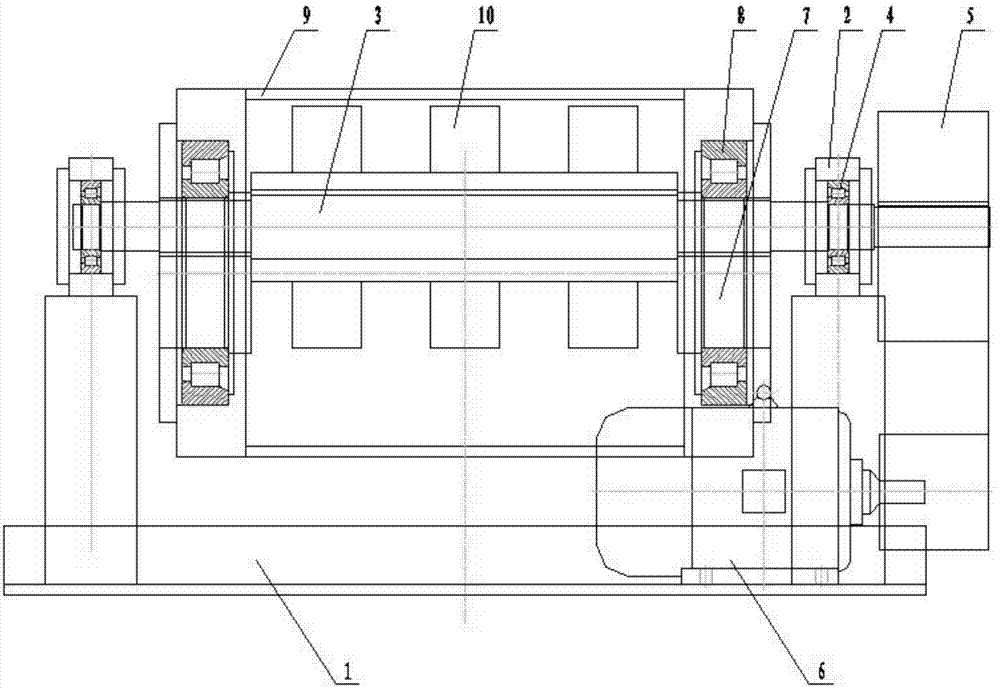

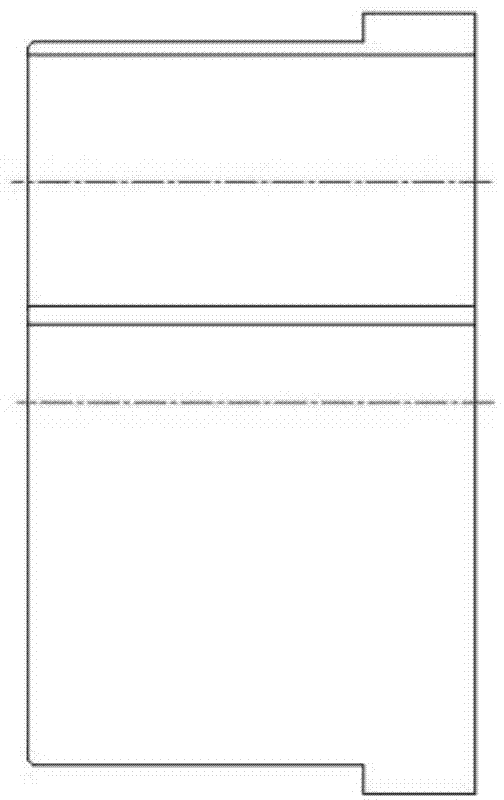

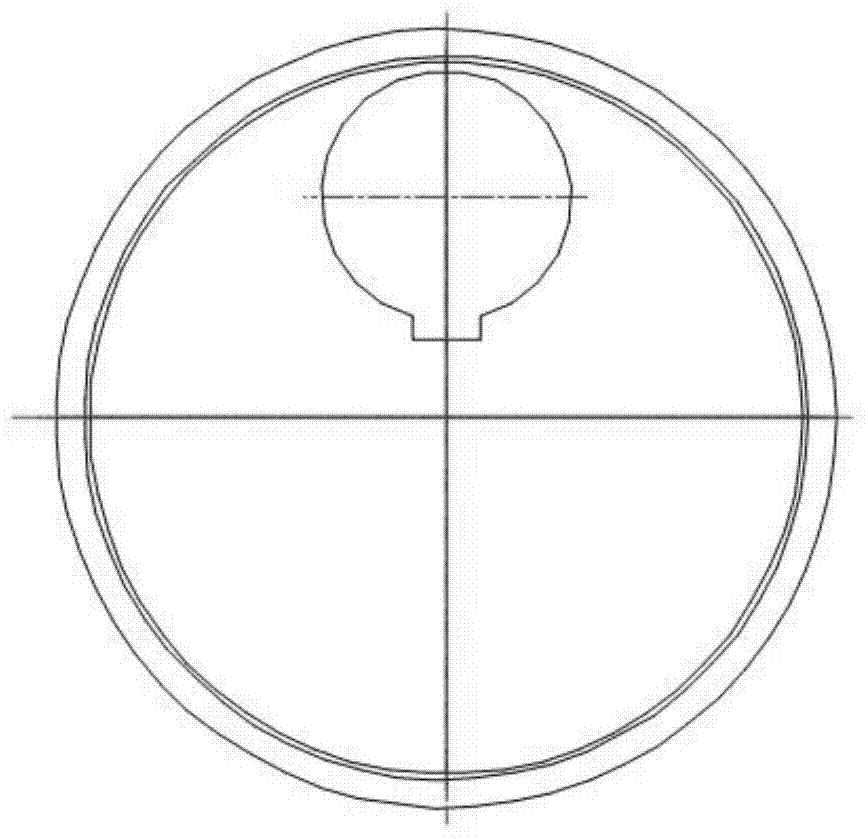

[0021] see Figure 1 to Figure 11 , the ball mill of the present embodiment comprises frame 1, from figure 1 It can be seen in the figure that the first bearing seat 2 is installed horizontally and symmetrically on the brackets at both ends of the frame 1, and the main shaft 3 is installed in the first bearing 4 inside the two first bearing seats 2; the right end of the main shaft 3 protrudes from the first bearing seat 2 and is rotated by the belt pulley 5, the belt pulley 5 is connected with the motor 6; the cylinder 9 is installed on the main shaft 3 through a pair of eccentric blocks 7 and the second bearing 8, the main shaft 3 is fixed in the eccentric block 7, the axis of the main shaft 3 Parallel to but not coincident with the center line of the eccentric block 7, the eccentric block 7 is fixedly connected to the inner ring of the seco...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com