Olefinic polymerization and copolymerization method of supported non-metallocene catalyst

A supported catalyst, non-metallocene technology, applied in the field of heterogeneous catalysts, can solve the problems of high equipment requirements and huge investment in fixed assets, and achieve the effect of high olefin polymerization activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

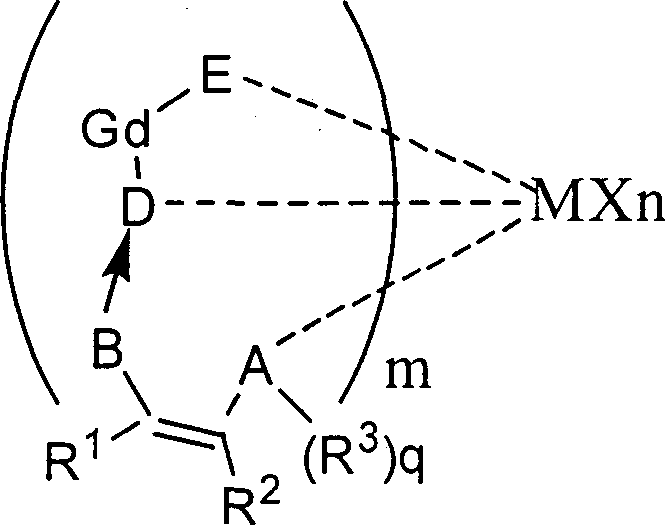

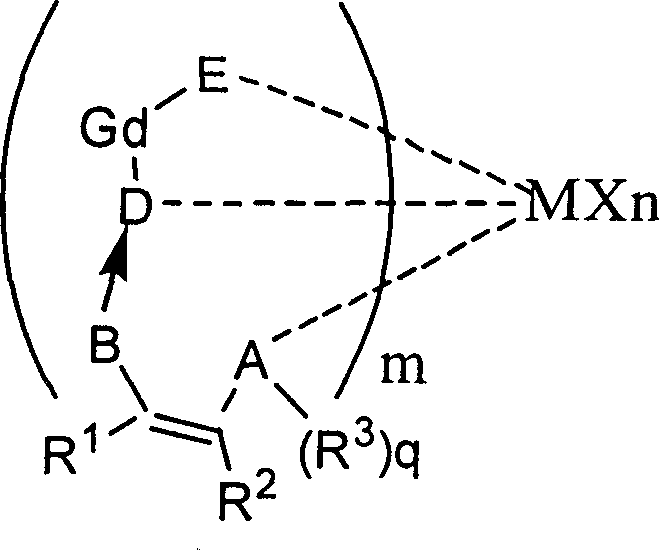

Method used

Image

Examples

Embodiment 1

[0118] Preparation of the supported catalyst: ES70 silica gel (product of Crosfield Company) was used for fluidization activation at a constant temperature of 650° C. for 6 h in a nitrogen atmosphere. Analytical pure magnesium chloride was calcined at 500°C for 3 hours to obtain anhydrous magnesium chloride. Under a nitrogen atmosphere (water and oxygen content are both lower than 5ppm), weigh 3 grams of anhydrous magnesium chloride, add 60ml of refined tetrahydrofuran (THF), then dropwise add 2.5ml of refined absolute ethanol, and then add 3g of heat-activated ES70 carrier , stirred and reacted at 20° C. for 18 h, washed the mixture with 30 ml×4 toluene, filtered, and finally dried in vacuum to obtain 5 g of composite carrier. Add 50ml of toluene to the composite carrier, drop 5ml of methylalumoxane (10wt% MAO in toluene) and 25ml of TiCl 4 (5v / v%TiCl 4 hexane solution), stirred at 20°C for 16 hours. Wash the mixed solution with 30ml×4 toluene, filter, and finally vacuum-d...

Embodiment 2

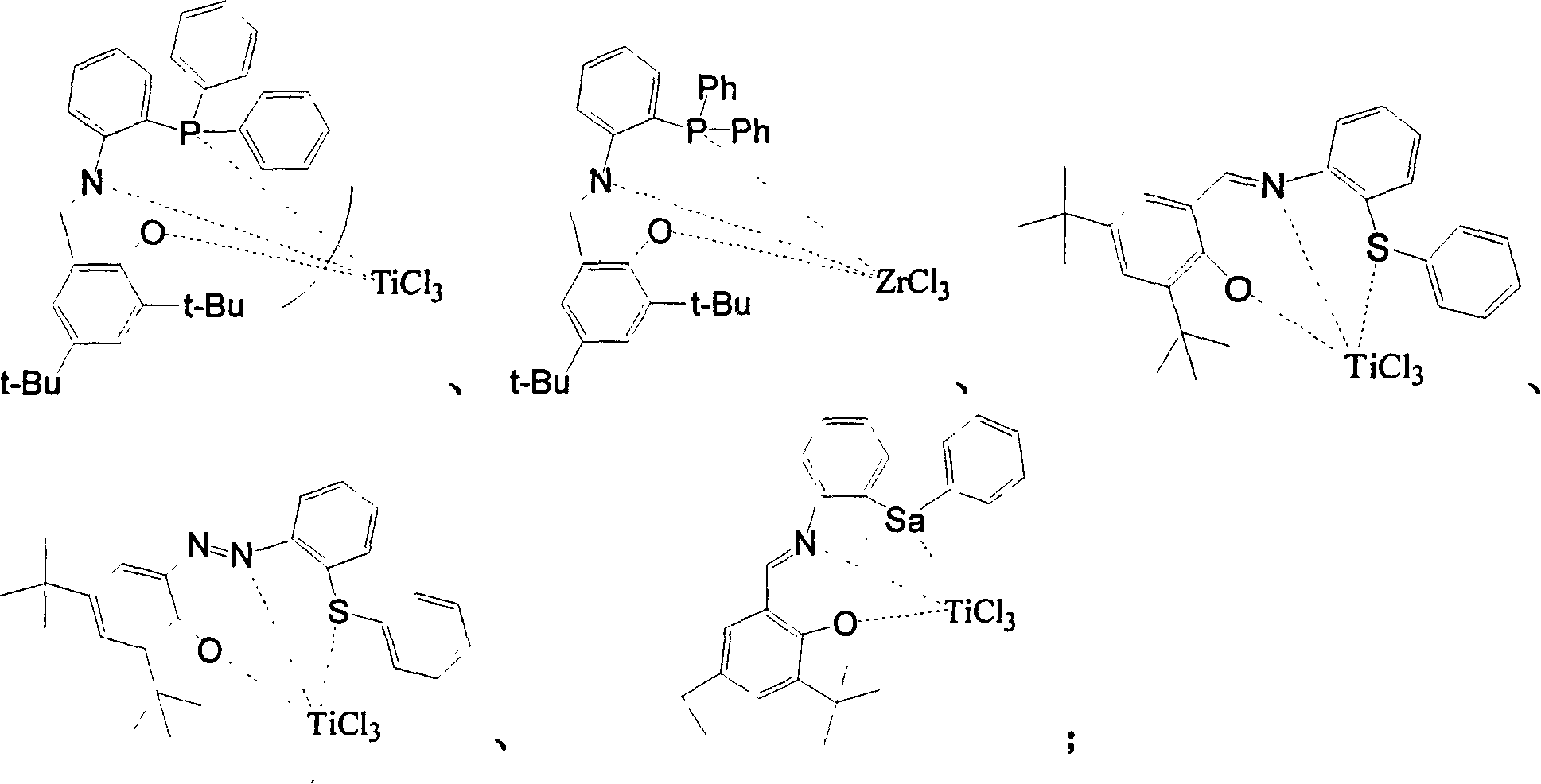

[0123] The preparation of supported catalyst is basically the same as in Example 1, but the non-metallocene catalyst selects the following structure:

[0124]

[0125] The cocatalyst adopts methyl aluminoxane;

[0126] The concentration of the supported catalyst is 0.01 g / L; the concentration of the co-catalyst is 0.0001 g / L;

[0127] The carrier adopts aluminum oxide;

[0128] The feeding method uses a non-metallocene catalyst and a cocatalyst to mix first, and then add it to the reactor;

[0129] Reaction solvent adopts toluene;

[0130] The reaction pressure is 0.1Mpa; the temperature is 100°C;

[0131] polymerized monomer is propylene

[0132] The reaction time was 1 hour.

Embodiment 3

[0134] The preparation of supported catalyst is basically the same as in Example 1, but the non-metallocene catalyst selects the following structure:

[0135]

[0136] Cocatalyst adopts ethyl aluminoxane;

[0137] The concentration of the supported catalyst is 1 gram / liter; the concentration of the co-catalyst is 100 grams / liter;

[0138] The carrier adopts: magnesium oxide;

[0139] The feeding method adopts non-metallocene catalyst and co-catalyst to add to the reactor respectively;

[0140] Reaction solvent adopts: heptane;

[0141] The reaction pressure is 2Mpa; the temperature is 10°C;

[0142] The polymerized monomer is: ethylene

[0143] The copolymerization monomer is: butene.

[0144] The reaction time was 3 hours.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com