High-voltage tantalum powder and preparation method thereof

A technology of tantalum powder and powder electricity is applied in the field of high-pressure tantalum powder and its preparation, which can solve the problems of low specific volume, simple tantalum powder particle shape, and inability to meet the requirements of high-capacity tantalum powder.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

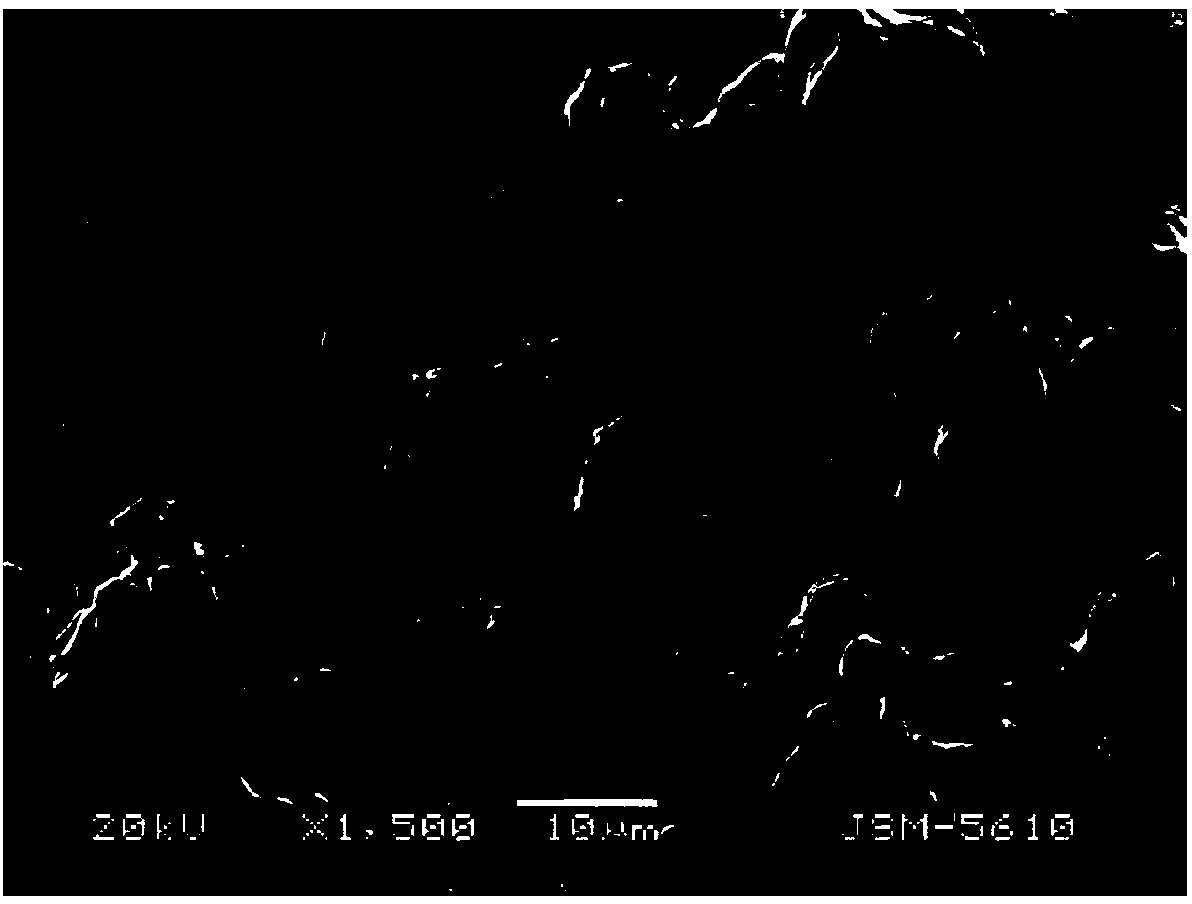

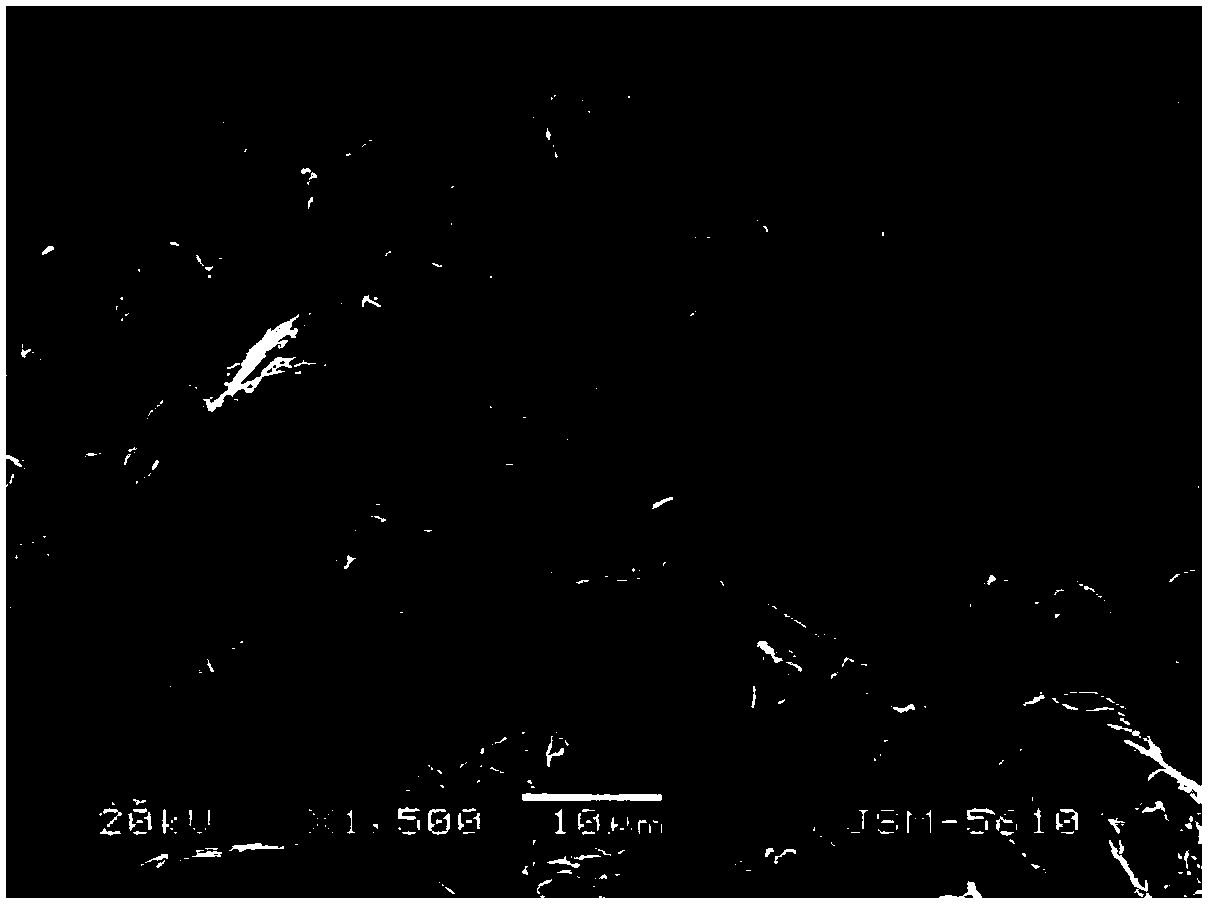

Image

Examples

Embodiment 1

[0083] Using high-purity tantalum ingots with a purity of 4N as raw materials, hydrogenation is carried out first. Hydrogenation process conditions: put high-purity tantalum ingots into a cleaned stainless steel crucible, then hoist them into the reaction bomb, and evacuate to 1×10 2 Below Pa, then filled with hydrogen to 1.0×10 5 Pa. Heat to raise the temperature, when the temperature rises to 800°C, keep the temperature for 3 hours. Pay close attention to the internal pressure of the bomb during the heating process, and it must not exceed 2.0×10 5 Pa, in order to prevent excessive pressure from cracking the hose and causing hydrogen leakage. After the heat preservation is over, power off and cool down for hydrogenation, and hydrogen will be replenished in time during the cooling process until the tantalum ingot no longer absorbs hydrogen. Then take out the hydrogenated tantalum ingot and put it into a mill and sieve machine for grinding and sieving to make powder. The ave...

Embodiment 2

[0092] Using high-purity tantalum ingots with a purity of 4N as raw materials, hydrogenation is carried out first. Hydrogenation process conditions: put high-purity tantalum ingots into a cleaned stainless steel crucible, then hoist them into the reaction bomb, and evacuate to 1×10 2 Below Pa, then filled with hydrogen to 1.0×10 5 Pa. Heat to raise the temperature, when the temperature rises to 800°C, keep the temperature for 3 hours. Pay close attention to the internal pressure of the bomb during the heating process, and it must not exceed 2.0×10 5 Pa, in order to prevent excessive pressure from cracking the hose and causing hydrogen leakage. After the heat preservation is over, power off and cool down for hydrogenation, and hydrogen will be replenished in time during the cooling process until the tantalum ingot no longer absorbs hydrogen. Then take out the hydrogenated tantalum ingot and put it into a mill and sieve machine for grinding and sieving to make powder. The ave...

Embodiment 3

[0101]Using high-purity tantalum ingots with a purity of 4N as raw materials, hydrogenation is carried out first. Hydrogenation process conditions: put high-purity tantalum ingots into a cleaned stainless steel crucible, then hoist them into the reaction bomb, and evacuate to 1×10 2 Below Pa, then filled with hydrogen to 1.0×10 5 Pa. Heat to raise the temperature, and when the temperature rises to 850°C, keep the temperature for 3 hours. Pay close attention to the internal pressure of the bomb during the heating process, and it must not exceed 2.0×10 5 Pa, in order to prevent excessive pressure from cracking the hose and causing hydrogen leakage. After the heat preservation is over, power off and cool down for hydrogenation, and hydrogen will be replenished in time during the cooling process until the tantalum ingot no longer absorbs hydrogen. Then take out the hydrogenated tantalum ingot and put it into a mill and sieve machine for grinding and sieving to make powder. The ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| breakdown voltage | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| oxygen content | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com