Nickel-hydrogen battery and preparation method for anode material

A nickel-metal hydride battery and positive electrode material technology, which is applied in the manufacture of electrodes, battery electrodes, and alkaline storage batteries, etc., and can solve problems such as battery performance degradation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0039] A preparation method for a nickel-metal hydride battery, comprising the following steps:

[0040] 1) Preparation of positive electrode.

[0041] Spherical nickel hydroxide coated with γ-CoOOH on the surface of partial nickel oxidation is used as the positive electrode active material, and the initial average valence state of nickel is controlled to be 2.08-2.20. The preparation method is as follows:

[0042] a) Add sodium hydroxide aqueous solution dropwise to the mixed solution of nickel sulfate, zinc sulfate and cobalt sulfate that is being stirred vigorously, and adjust the pH value between 13 and 14 to uniformly precipitate zinc and cobalt doped in the solution Spherical nickel hydroxide, the reaction speed is controlled so that the mass ratio of metal nickel, metal zinc and metal cobalt in the precipitated spherical nickel hydroxide is 57:3.0:1.4.

[0043] B) add 10%~25% CoSO in the solution that has separated out nickel hydroxide Aqueous solution, keep the pH val...

Embodiment 1

[0052] According to the method described above, the positive electrode adopts the spherical nickel hydroxide whose initial valence state of nickel is 2.15 as the positive electrode active material; the positive and negative electrode capacity ratio is 1.0:1.25 to determine the amount of powder N on the negative electrode; the battery is in the formation process There is a discharge step, that is, before the battery is fully activated, the average valence state of nickel in the positive electrode active material is oxidized and then reduced to 2.08-2.20 valence (chemical formation process 1). The battery prepared by this manufacturing process and formation process is battery A1.

Embodiment 2

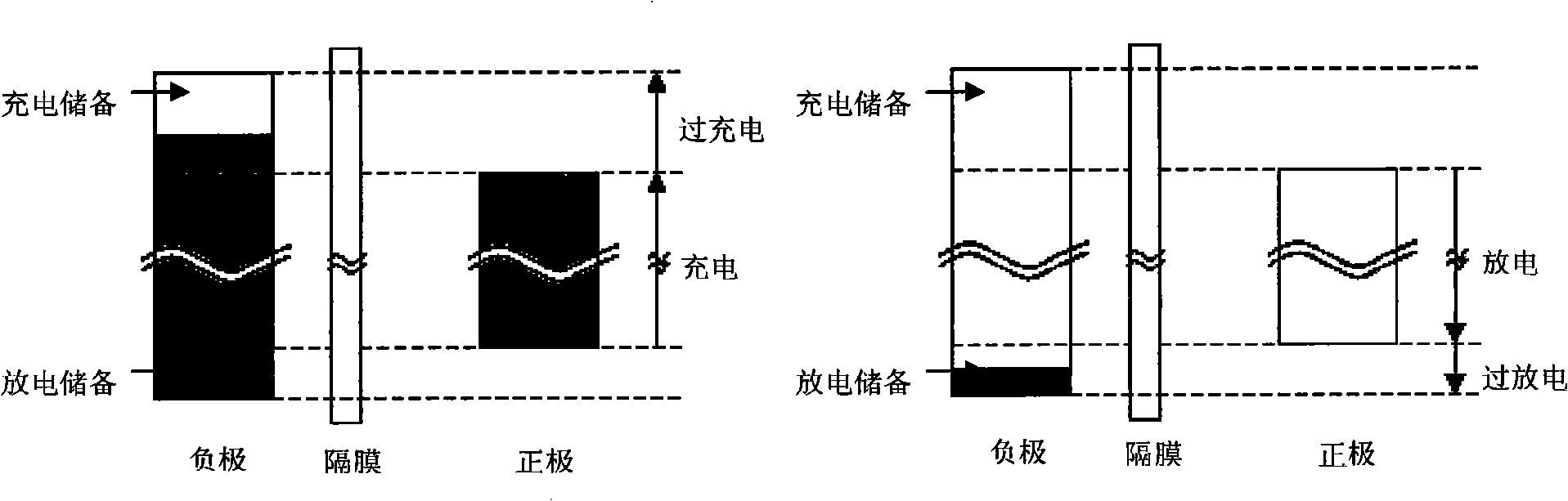

[0060] The positive electrode adopts the spherical nickel hydroxide whose initial valence state of nickel is 2.15 and the surface of partial nickel oxide is coated with γ-CoOOH as the positive electrode active material; the amount of powder N on the negative electrode is determined according to the positive and negative electrode capacity ratio of 1.0:1.25; the battery is in the formation process There is a discharge step, that is, before the battery is fully activated, the average valence state of nickel in the positive electrode active material is oxidized and then reduced to 2.08-2.20 valence (chemical formation process 1). The battery prepared by this manufacturing process and formation process is battery B1. Test its overcharge, cycle performance and negative discharge reserve.

[0061] The test method for the overcharge performance of the Ni-MH battery is as follows: after the formation, the battery is put into 1.0V at a rate of 0.2C, and charged at 1C for 92min. It is r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com