Middle-low-speed normal conducting maglev vehicle motor stator winding multi-segment distribution structure

A technology for motor stator and stator winding, which is applied to the shape/style/structure of winding conductors, electric components, electrical components, etc., and can solve problems such as cannot be easily reduced, large reactive magnetizing current, and large reactive magnetizing current of motor. , to achieve the effect of improving efficiency and power factor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

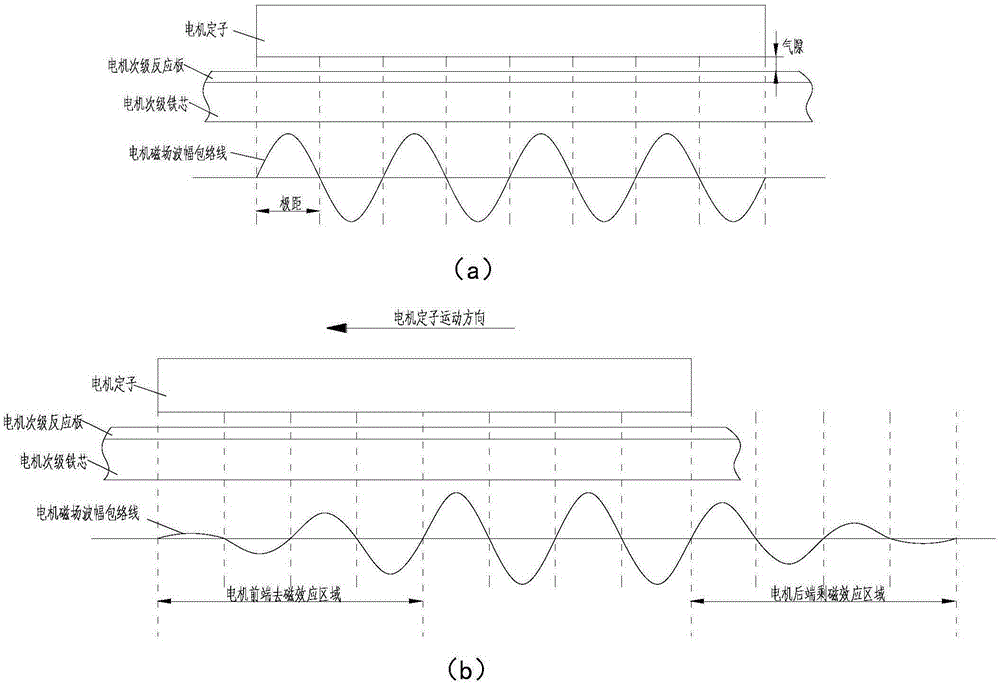

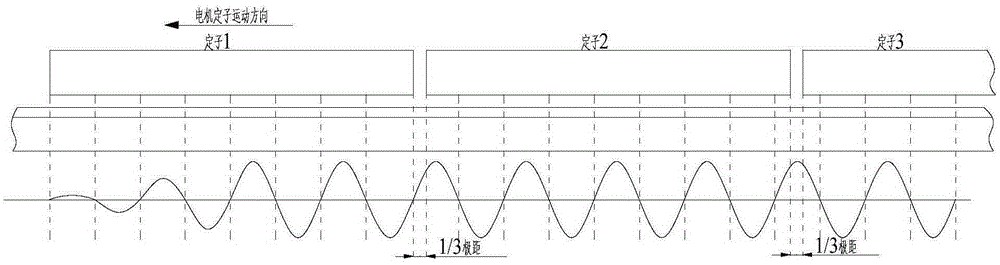

[0023] There are currently maglev vehicles independently developed by Japan or my country. They are composed of 5 bogies. The length of the bogies is about 3000mm. There are 2 linear motors on each bogie. The gap between linear motors is about 900mm, such as Figure 4 shown. When the train is running, the magnetic field at the front end of the motor is weakened, reducing the traction force of the motor; while the attenuated residual magnetic field at the rear end of the motor produces a magnetic pull force in the opposite direction to the traction force, which also reduces the traction force of the motor. Therefore, the front and rear end effects of the motor reduce the efficiency of the motor.

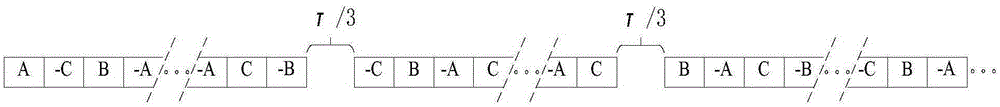

[0024] Specifically, there is a 5-magnet bogie maglev vehicle with a maximum speed of 100km / h and a full load of about 25t. There are five 50kW linear traction asynchronous motors on each side of the vehicle. The designed rated voltage of the motor is 240V, and the pole distance τ= 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com