Variable-frequency refrigerant pump inlet cavitation-erosion-resistant system and control method thereof

A refrigerant pump, anti-cavitation technology, applied in refrigerators, refrigeration components, refrigeration and liquefaction, etc., can solve problems such as unfavorable on-site installation and product promotion, can not guarantee the avoidance of refrigerant pumps, low reliability, etc., to reduce The effect of refrigerant charge, reduction of design capacity, and reliable operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

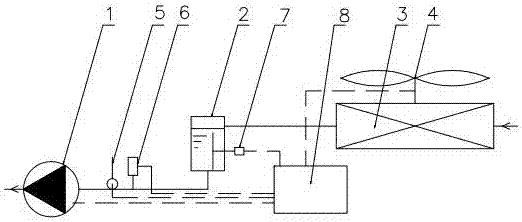

[0040] An anti-cavitation system at the inlet of a variable frequency refrigerant pump in this embodiment, such as figure 1 As shown, it includes a refrigerant pump 1, a liquid receiver 2, a condenser 3, a fan 4, a refrigerant temperature sensor 5, a refrigerant pressure sensor 6, a liquid level sensor 7 and a controller 8; the output end of the condenser 3 is connected to the storage The input end of the liquid receiver 2 is connected, the output end of the liquid receiver 2 is connected to the input end of the refrigerant pump 1, the refrigerant temperature sensor 5 and the refrigerant pressure sensor 6 are installed on the inlet pipeline of the refrigerant pump 1, and the liquid level The sensor 7 is connected to the liquid receiver 2, and the fan 4 is connected to the condenser 3; wherein, the refrigerant pump 1, the fan 4, the refrigerant temperature sensor 5, the refrigerant pressure sensor 6 and the liquid level sensor 7 are electrically connected to the controller 8 res...

Embodiment 2

[0047] The control method of the anti-cavitation system at the inlet of a variable frequency refrigerant pump according to this embodiment includes the following points:

[0048] 1) When it is detected that the subcooling degree of the refrigerant drops to the lower limit value set for the subcooling degree, start to increase the speed of the fan 4 to increase the subcooling degree of the refrigerant until the subcooling degree of the refrigerant reaches the supercooling degree If the temperature setting value is lower than the set value, the speed regulation of the fan 4 is stopped and the current speed is kept constant, and the speed of the refrigerant pump 1 remains unchanged during this process;

[0049] 2) If the speed of the fan 4 reaches the maximum value, but the subcooling degree still cannot reach the set value of the supercooling degree, the fan 4 will keep running at the maximum speed, and the speed of the refrigerant pump 1 will remain unchanged;

[0050]3) If the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com