Device and method for adjusting powder quantity deviation of powder pipes of direct blowing type pulverizing system

A pulverizing system and direct blowing technology, which is applied in the direction of combustion method, block/powder fuel preparation, block/powder supply/distribution, etc. It can solve the problems of unbalanced combustion output, large thermal deviation, and difficult control, etc. problems, achieve the effect of reducing wear, eliminating thermal deviation, and reducing powder volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033]This embodiment discloses a device specially used to adjust the powder volume of each powder tube of the coal mill, and adjust the powder volume of each powder tube without affecting the air volume leveling of each powder tube, so as to achieve leveling The purpose of the amount of powder in each powder pipe of the coal mill is to eliminate the problem of large deviations in the combustion heat of the boiler caused by the uneven distribution of powder in each powder pipe of the coal mill, to prevent or weaken the local overheating of each heating surface at the furnace outlet, and to protect the heating surface , so that the boiler operates efficiently, safely and economically.

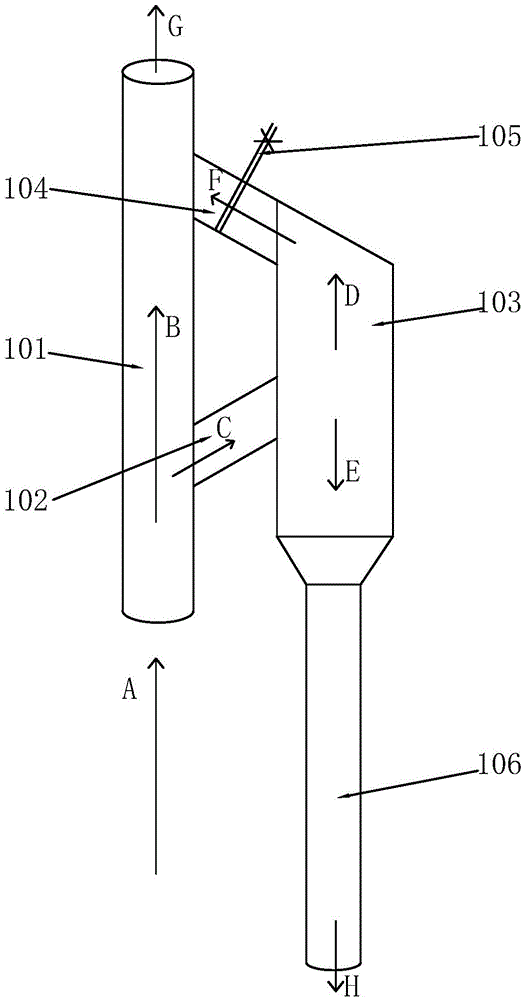

[0034] Such as figure 1 As shown, a device for adjusting the powder amount deviation of each powder pipe of the direct blowing type powder making system includes a main powder pipe 101, and an air-powder separation cylinder 103 is arranged on the side of the main powder pipe 101, and the main po...

Embodiment 2

[0045] Due to the deviation of the amount of powder in the primary air leveling method of the existing direct blowing type pulverizing system, the combustion intensity of the furnace is uneven, which has a negative impact on the economical and safe operation of the boiler. The method for the deviation of the amount of powder in each powder tube of the powder making system.

[0046] The invention discloses a method for adjusting the powder quantity deviation of each powder tube of a direct blowing type pulverizing system, which comprises the following steps:

[0047] S1: Set the first branch pipe 102 on the upstream main powder pipe 101 to form the first air powder bypass, and connect the air powder bypass with the air powder separation cylinder 103 arranged on the side of the main powder pipe 101, so that once The wind powder enters the wind powder separation cylinder 103;

[0048] By setting the first branch pipe 102, after the primary air powder enters the main powder pipe ...

Embodiment 3

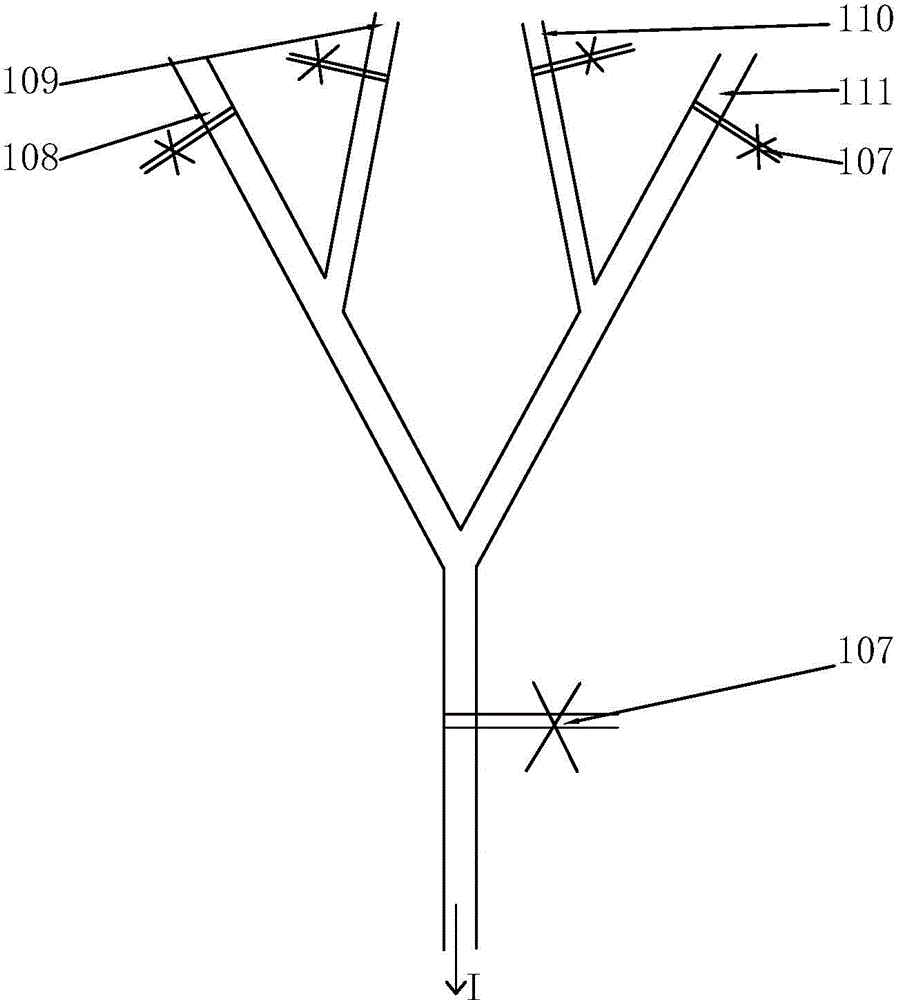

[0060] Such as figure 2 As shown, in this embodiment, an air locker 107 is provided between the pulverized coal downcomer 106 and the coal feeder. For the existing 300MW four-corner tangential combustion boiler, the medium-speed mill direct-blowing pulverization system, the outlet of a single mill has 4 main powder pipes 101, which are respectively the first powder pipe 108, the second powder pipe 109, and the third powder pipe 110 , the fourth powder pipe 111, on each of the above-mentioned main powder pipes 101, install figure 1 The adjustment device described in is used to adjust the deviation of the powder amount of each main powder pipe 101. Air lockers 107 are arranged on each pulverized coal downcomer 106 .

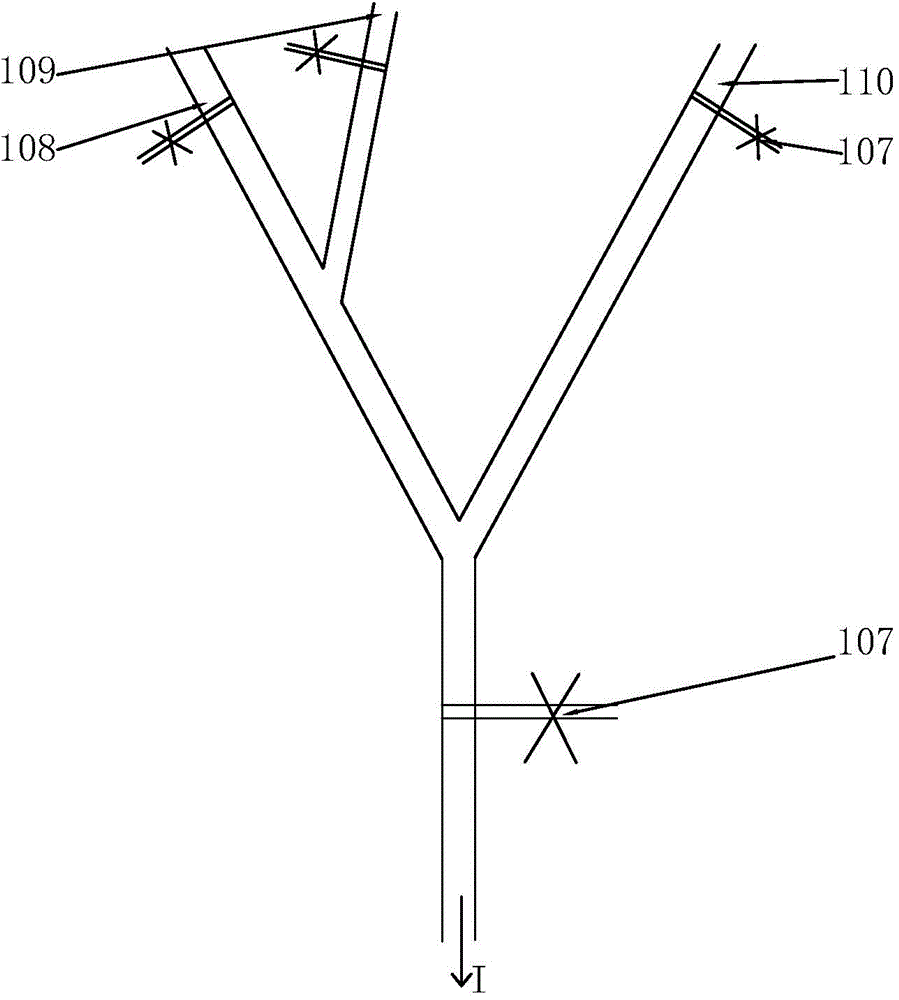

[0061] Such as image 3 As shown, for a 660MW opposed combustion boiler, a medium-speed mill direct-blowing pulverization system, there are three main powder pipes 101 at the outlet of a single mill, which are respectively the first powder pipe 108, the second ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com