LCD screen manufacturing technology making PI liquid and spacer mixed

A production process and display technology, applied in optics, instruments, nonlinear optics, etc., can solve the problems of reduced production rate of defective products, high production rate of defective products, poor mixing effect, etc., to ensure the mixing effect and avoid powder aggregation , Improve the effect of curing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] All features disclosed in this specification, or steps in all methods or processes disclosed, may be combined in any manner, except for mutually exclusive features and / or steps.

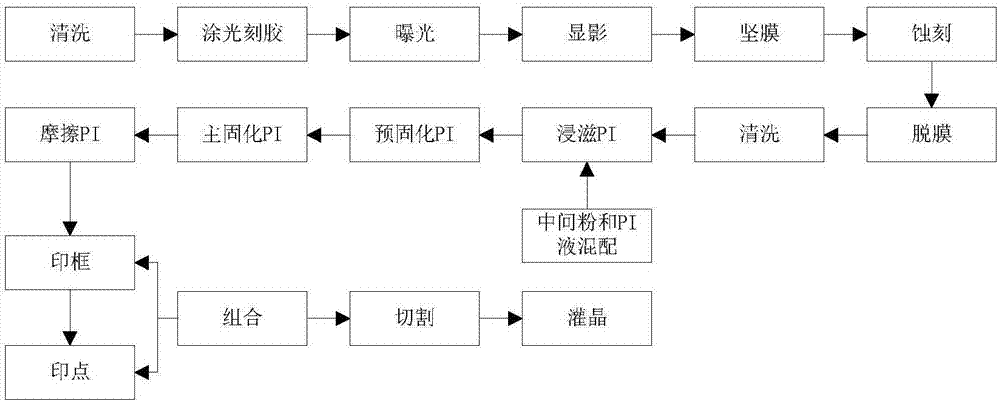

[0020] A kind of LCD display screen manufacturing process that PI liquid and intermediary powder are mixed comprises the following steps:

[0021] Pretreatment: perform the first cleaning, photoresist coating, exposure, development, film hardening, etching, stripping and second cleaning in sequence to obtain the ITO glass substrate;

[0022] Soaking and curing PI: Soaking PI with the mixed solution obtained by mixing PI liquid and intermediate powder twice on the ITO glass substrate, after soaking PI, pre-curing PI and main curing PI in turn to obtain a cured ITO glass substrate; Among them, the mixing of PI liquid and intermediate powder includes the first mixing and the second mixing. The first mixing is mixed according to the provided ratio. If the provided ratio is 1 / 100, a digital display...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com