Automatic production and packaging production line for particulate biological organic fertilizer

A bio-organic fertilizer and packaging line technology, applied in organic fertilizers, fertilization devices, fertilizer mixtures, etc., can solve the problems of low degree of automation of production technology, easy to produce pollution, cumbersome processes, etc., to prolong placement time and reduce labor intensity. , The effect of particle shape is good

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

[0021] Such as figure 1 Shown, is an embodiment of the present invention,

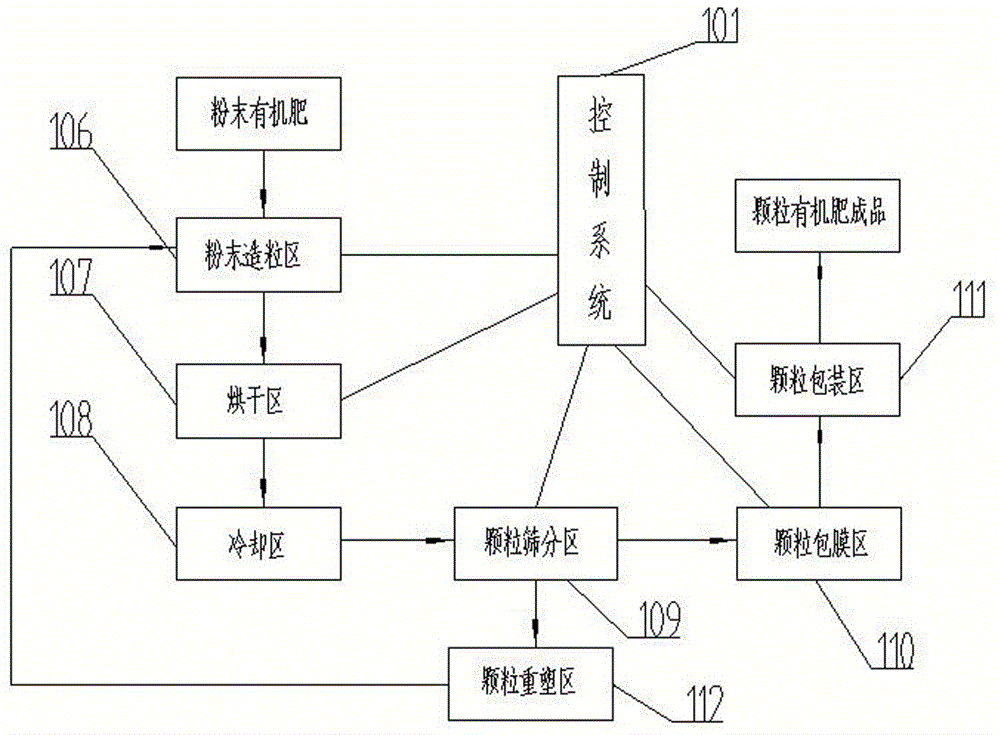

[0022] An automated production and packaging line for granular bio-organic fertilizers, including a powder granulation area 106, a drying area 107, a cooling area 108, a particle screening area 109, a particle coating area 110, a particle packaging area 111, and a particle remodeling area 112. Control system 101 and environmental protection equipment compatible with each processing area. The powdered organic fertilizer is first conveyed to the powder granulation area 106, and the powder granulation area 106 makes the powdered organic fertilizer into granules through the tooth-stirring granulation process and is transported to the drying area 107, and the drying area 107 is dried due to The moisture in the granular material produced by the tooth-stirring gran...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com