Processing method of applying waste desulfurizing agents to sintering

A treatment method and desulfurization agent technology, applied in the fields of metallurgy and material science, can solve the problems of high sulfur content of waste desulfurizers, secondary pollution, smog disasters, etc., and achieve a mature and reliable process plan, reduce treatment costs, and reduce production costs. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

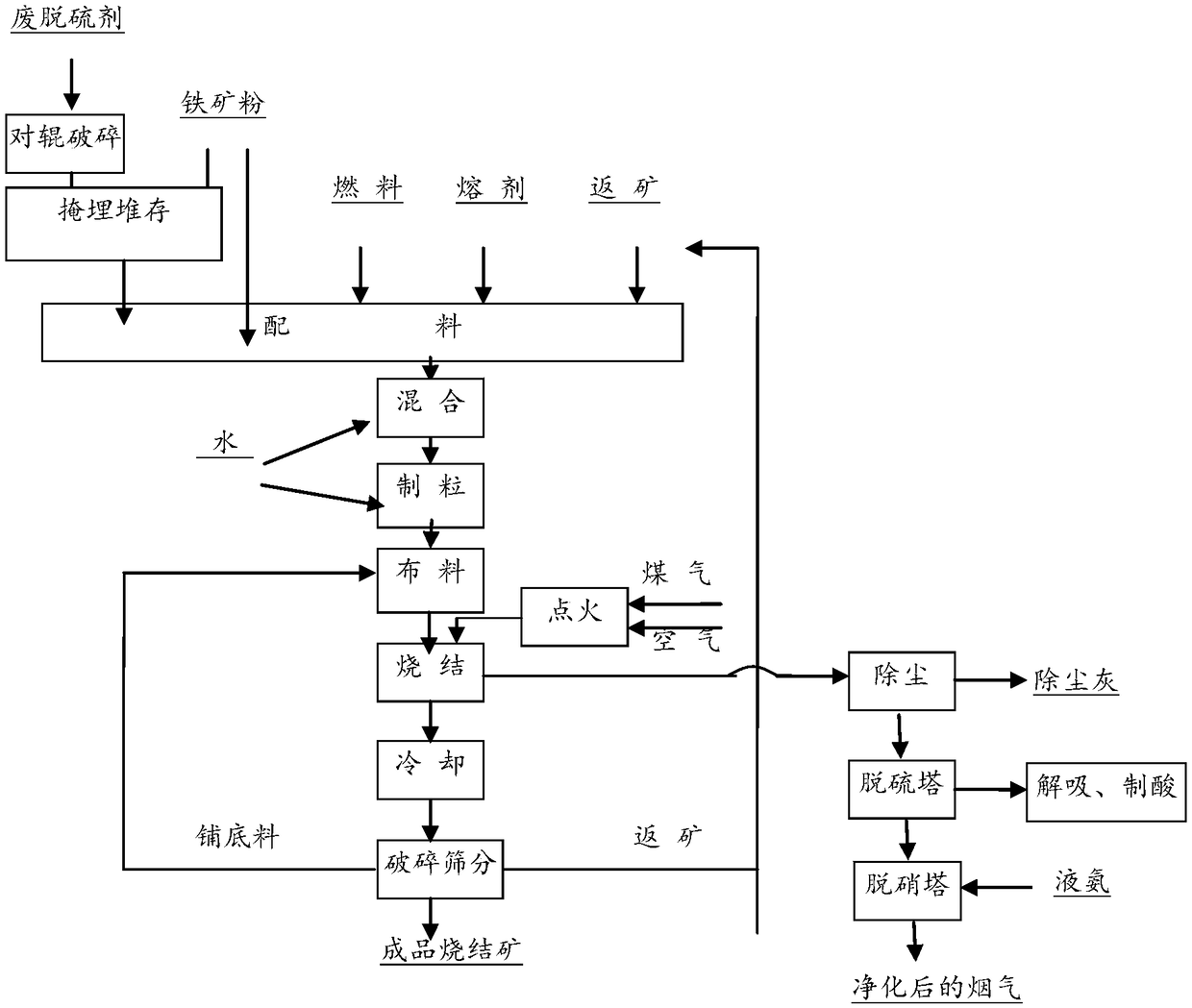

[0049] A treatment method for applying waste desulfurizer to sintering, comprising the following steps:

[0050] (1) Crushing of waste desulfurizer: take waste desulfurizer, its main chemical composition is 9.10% TFe, 32.29% S, 25.90% CaO, 0.9% MgO, 1.0% SiO 2 ; LOI value was 35.66%. The original particle size of waste desulfurizer is 3-10mm, accounting for 95%, of which 8-10mm accounts for about 35%. The above-mentioned waste desulfurizer is crushed with a double-roll crusher until the particle size is less than 8mm, accounting for 100% (of which less than 1mm accounts for 10%).

[0051] (2) Landfill stockpiling of waste desulfurizers: first mix the crushed waste desulfurizers with iron ore powder containing about 60% iron at a mass ratio of 1:10 to obtain a mixed powder containing waste desulfurizers. Then the mixed material is buried in the iron ore homogeneous ore powder stockpile containing about 60% iron at a mass ratio of 0.184:99.816, and the mixed ore powder contain...

Embodiment 2

[0065] A treatment method for applying waste desulfurizer to sintering, comprising the following steps:

[0066] (1) Crushing of waste desulfurizer: take waste desulfurizer, its main chemical composition is 9.10% TFe, 32.29% S, 25.90% CaO, 0.9% MgO, 1.0% SiO 2 ; LOI value is 35.66%; the original particle size of waste desulfurizer is 3-10mm, accounting for 95%, of which 8-10mm accounts for about 35%. The above-mentioned waste desulfurizer is crushed with a double-roll crusher until the particle size is less than 8mm, accounting for 100% (of which less than 1mm accounts for 10%).

[0067](2) Landfill stockpiling of waste desulfurizers: first mix the crushed waste desulfurizers with iron ore powder containing about 60% iron at a mass ratio of 1:10 to obtain a mixed powder containing waste desulfurizers. Then, the mixed powder is buried in the iron ore homogeneous powder stockpile containing about 60% iron at a mass ratio of 0.913:99.087, and the mixed ore powder containing 59.6...

Embodiment 3

[0080] A treatment method for applying waste desulfurizer to sintering, comprising the following steps:

[0081] (1) Crushing of waste desulfurizer: take waste desulfurizer, its main chemical composition is 9.10% TFe, 32.29% S, 25.90% CaO, 0.9% MgO, 1.0% SiO 2 ; LOI value is 35.66%; the original particle size of waste desulfurizer is 3-10mm, accounting for 95%, of which 8-10mm accounts for about 35%. The above-mentioned waste desulfurizer is crushed with a double-roll crusher until the particle size is less than 8mm, accounting for 100% (of which less than 1mm accounts for 10%).

[0082] (2) Landfill stockpiling of waste desulfurizers: first mix the crushed waste desulfurizers with iron ore powder containing about 60% iron at a mass ratio of 1:10 to obtain a mixed powder containing waste desulfurizers. Then the mixed material is buried in the iron ore homogeneous ore powder stockpile containing about 60% iron according to the mass ratio of 1.837:98.163, and the mixed ore powd...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com