Powder removal brushing part for artware processing course

A processing and handicraft technology, applied in the direction of wood processing utensils, manufacturing tools, cleaning methods and utensils, etc., can solve the problems affecting the finished product, affecting the accuracy of the processing position, etc., and achieve the effect of improving the accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

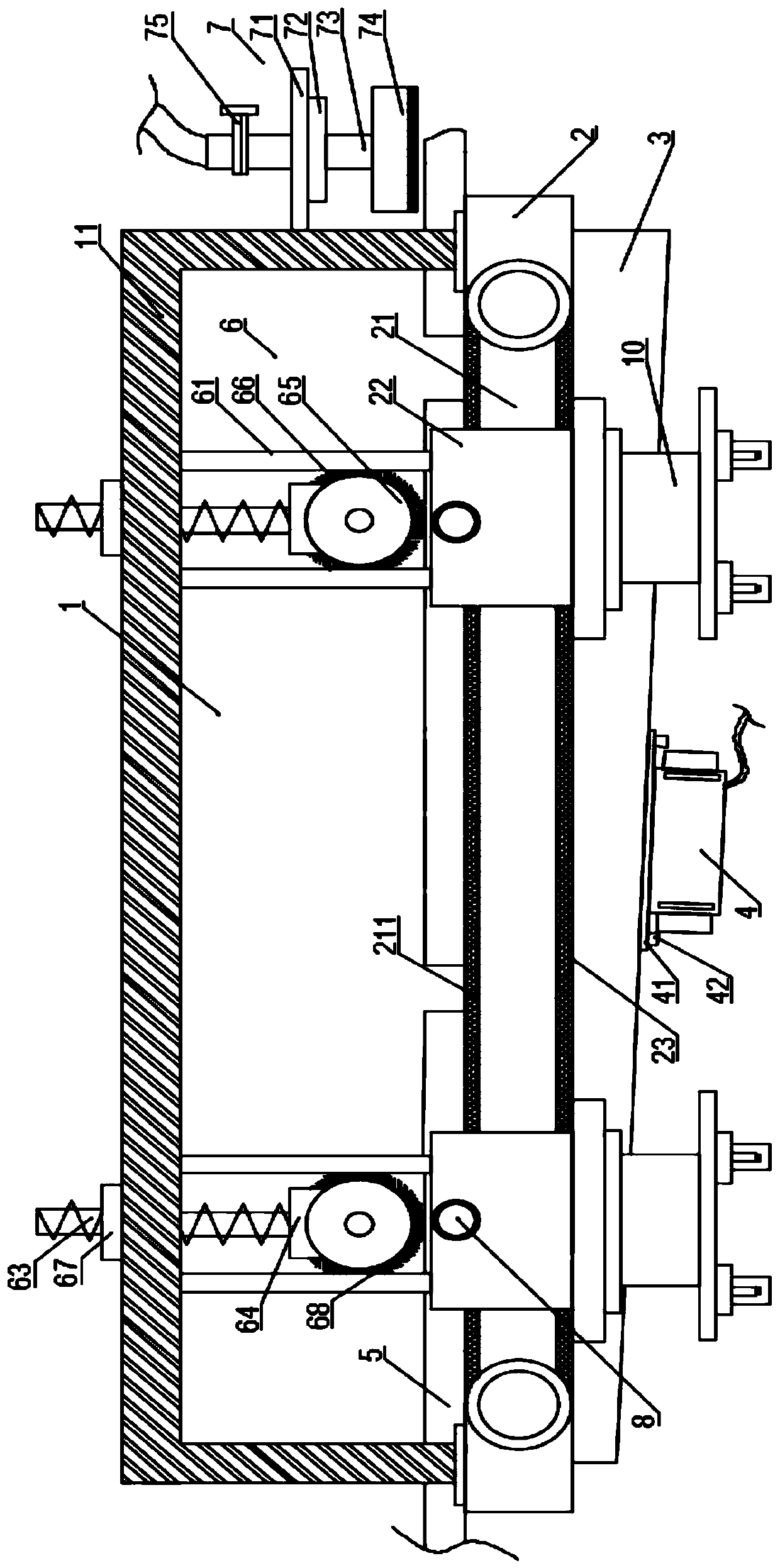

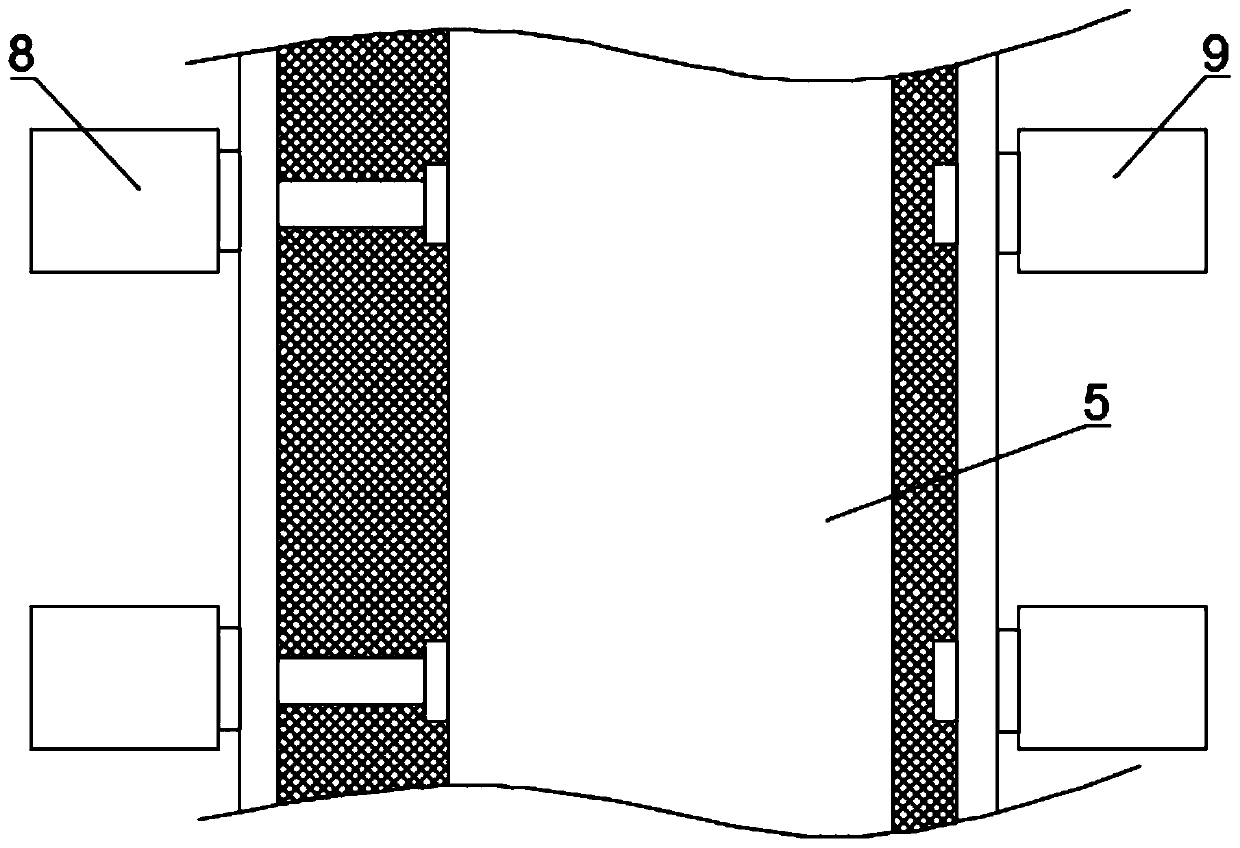

[0020] See Figure 1-2 As shown, the powder removing brush for the crafts processing process of the present invention includes an operating chamber 1. A support plate 11 is provided on the outer side of the operating chamber 1, and both left and right ends of the support plate 11 are provided for pressing. For the bristle mechanism 6 of the plate 5 to be processed, a workbench 2 is provided under the support plate 11, and the workbench 2 is provided with a conveying belt 21 from left to right. The front and rear ends of the workbench 2 are both The side support 22, the conveyor belt 21 is a plastic conveyor belt with a blanking grid 211, a collection bin 3 is provided under the workbench 2, and a collection bin 3 is provided between the collection bin 3 and the workbench 2. There is a connected discharging port 23, the support frame 61 of the bristle mechanism 6 is installed on the side support table 22, the middle of the support frame 61 is provided with a pressure roller 66, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com