Preparation method of hollow microsphere calcium carbonate

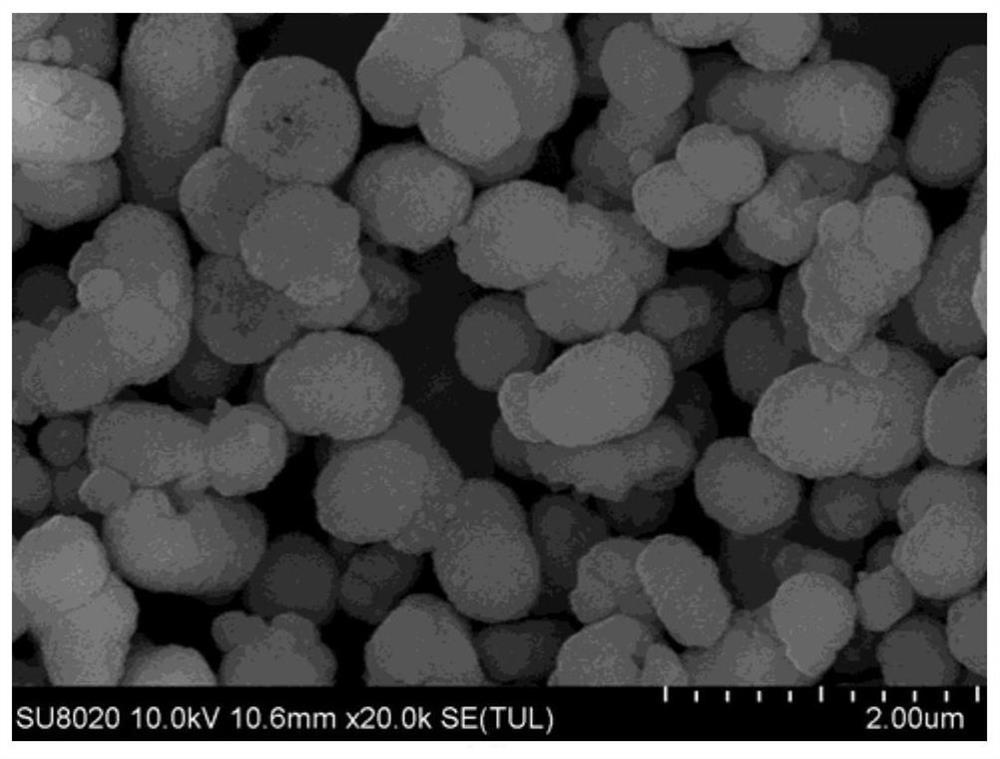

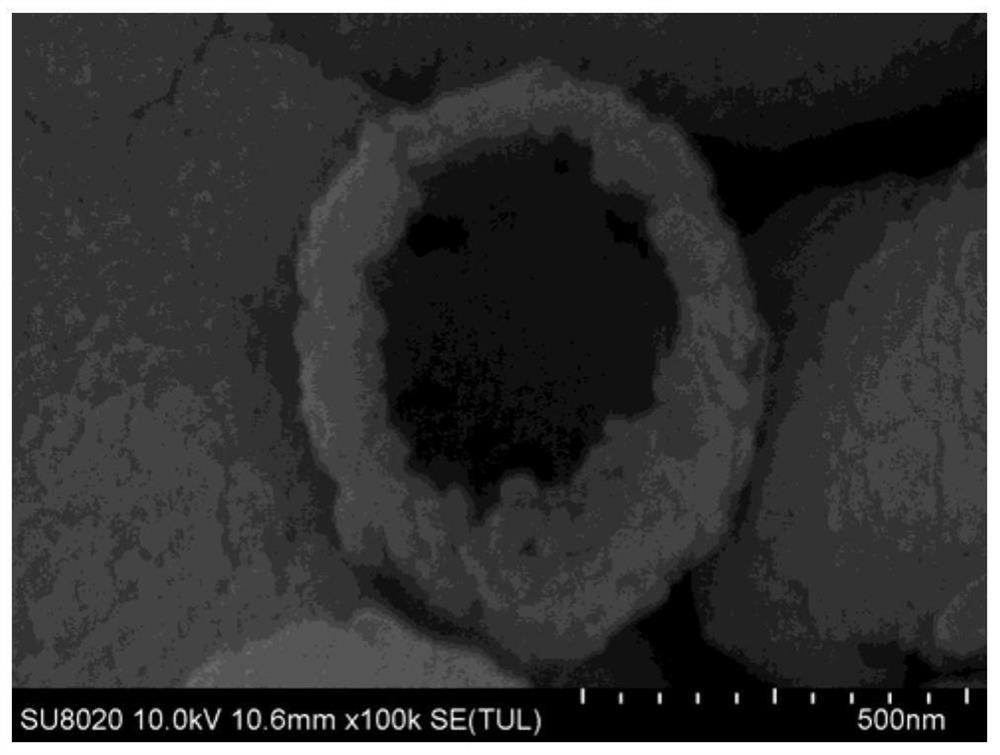

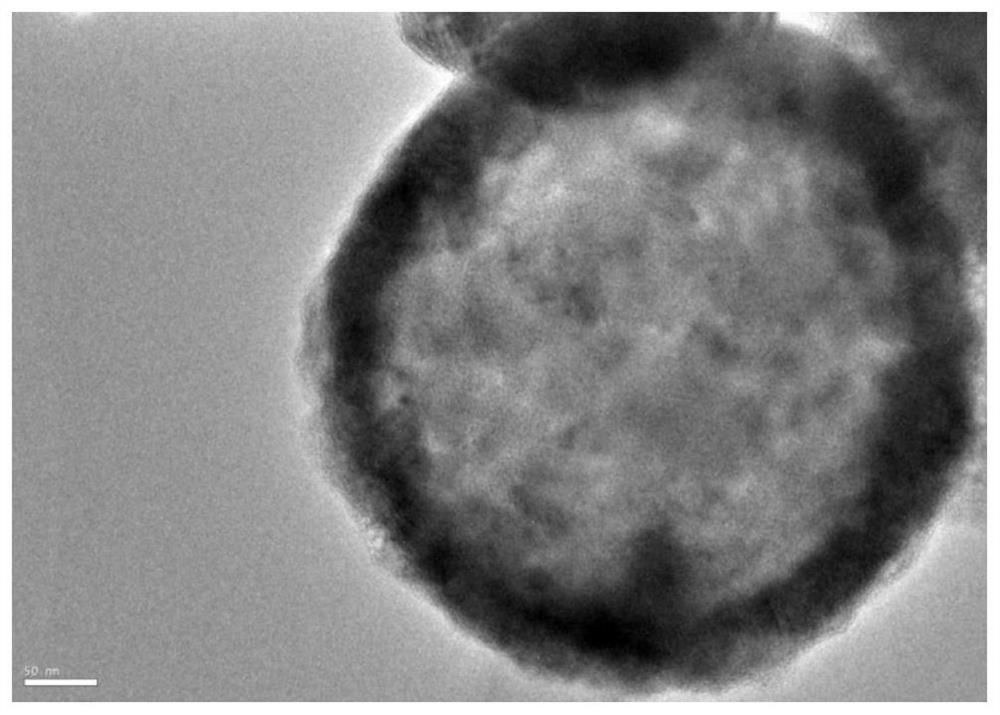

A technology of calcium carbonate and microspheres, applied in the fields of calcium carbonate/strontium/barium, chemical instruments and methods, calcium/strontium/barium compounds, etc. Uneven particle size distribution and other problems, to achieve the effect of high yield, low production cost and uniform shape

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] Present embodiment is an example of the preparation method of hollow microsphere calcium carbonate of the present invention, comprises the following steps:

[0037]S1. Accurately weigh calcium oxide and dissolve it in deionized water, heat it to 80°C in a constant temperature water bath, stir for 2 hours, let it stand for 12 hours, digest it for 24 hours, remove the residue after passing through a 200-mesh sieve, adjust the concentration, and obtain a raw material concentration of 2 % calcium hydroxide slurry;

[0038] S2. Get 180ml of the prepared calcium hydroxide slurry and move it into the high-pressure micro-reactor, add 2% EDTA in the molar ratio of the calcium hydroxide slurry concentration, seal the high-pressure micro-reactor, open the heating device and the stirring device, and mix the solution at temperature at 80°C, at a speed of 50r·min -1 and access to CO 2 The gas increases the pressure in the reactor by 1 MPa to react for 4 hours to obtain the product ...

Embodiment 2

[0041] Present embodiment is another example of the preparation method of hollow microsphere calcium carbonate of the present invention, comprises the following steps:

[0042] S1. Accurately weigh calcium oxide and dissolve it in deionized water, heat it to 80°C in a constant temperature water bath, stir for 2 hours, let it stand for 12 hours, digest it for 24 hours, remove the residue after passing through a 200-mesh sieve, adjust the concentration, and obtain a raw material concentration of 2 % calcium hydroxide slurry;

[0043] S2. Get 180ml of the prepared calcium hydroxide slurry and move it into the high-pressure micro-reactor, add 2% EDTA in the molar ratio of the calcium hydroxide slurry concentration, seal the high-pressure micro-reactor, open the heating device and the stirring device, and mix the solution at temperature at 100°C, at a speed of 50r·min -1 and access to CO 2 The gas increases the pressure in the reactor by 1 MPa to react for 4 hours to obtain the p...

Embodiment 3

[0046] Present embodiment is another example of the preparation method of hollow microsphere calcium carbonate of the present invention, comprises the following steps:

[0047] S1. Accurately weigh calcium oxide and dissolve it in deionized water, heat it to 80°C in a constant temperature water bath, stir for 2 hours, let it stand for 12 hours, digest it for 24 hours, remove the residue after passing through a 200-mesh sieve, adjust the concentration, and obtain a raw material concentration of 2 % calcium hydroxide slurry;

[0048] S2. Get 180ml of the prepared calcium hydroxide slurry and move it into the high-pressure micro-reactor, add 2% EDTA in the molar ratio of the calcium hydroxide slurry concentration, seal the high-pressure micro-reactor, open the heating device and the stirring device, and mix the solution at temperature at 120°C, at a speed of 50r·min -1 and access to CO 2 The gas increases the pressure in the reactor by 1 MPa to react for 4 hours to obtain the p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com