Methods for preparing titanium alloy TC4 prill by plasma auxiliary rotation electrode

A technology of auxiliary rotation and metal balls, which is applied in the field of metal material preparation, can solve the problems of small ball diameters and the inability of titanium alloy TC4 metal balls to meet the needs of laser three-dimensional forming and electron beam forming processes, and achieve small ball diameters and high Mechanical properties, effect of narrow powder particle size range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

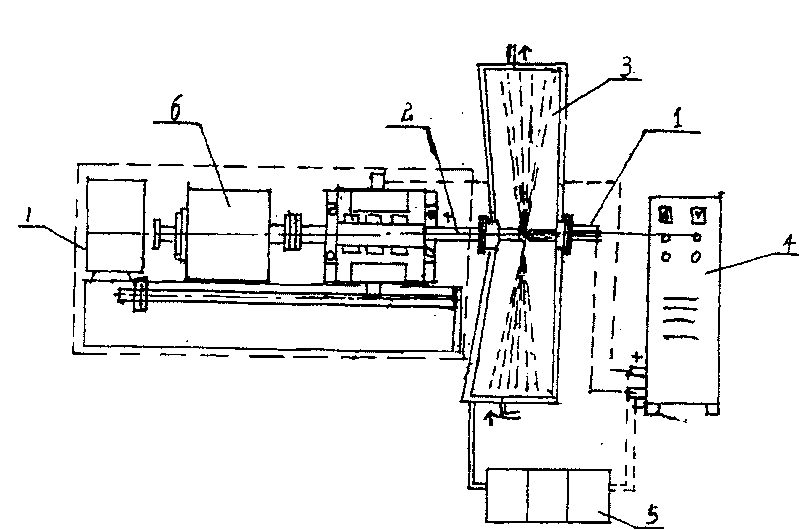

Image

Examples

Embodiment Construction

[0018] The method for preparing titanium alloy TC4 metal pellets by using a plasma-assisted rotating electrode is implemented according to the following steps:

[0019] (1) Preparation of anode electrode rods: the titanium alloy TC4 metal is refined into standard rods, and then it is refined into equipment capable of producing spherical powder with a plasma gun rotating electrode at a high speed of 9000-13000 revolutions per second The motor rod running smoothly in the dynamic seal; the preparation process of the electrode rod is as follows: a. According to the national standard, the chemical composition ratio of titanium alloy TC4 is obtained to obtain the melting and casting raw material; b. The qualified melting and casting raw material is vacuum smelted to obtain the relative An ingot-shaped billet with a density of more than 70%; c. The vacuum-melted ingot-shaped billet is hot-forged to obtain a titanium alloy TC4 metal rod with a relative density greater than 97%; d. The ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com