Titanium dioxide hollow nanospheres and preparation method thereof

A technology of titanium dioxide and hollow spheres, which is applied in the field of nanomaterials, can solve problems such as unsuitability for large-scale production, reduced photocatalytic activity, and complicated process flow, so as to inhibit the growth and condensation process, improve product purity, and have high photocatalytic activity. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

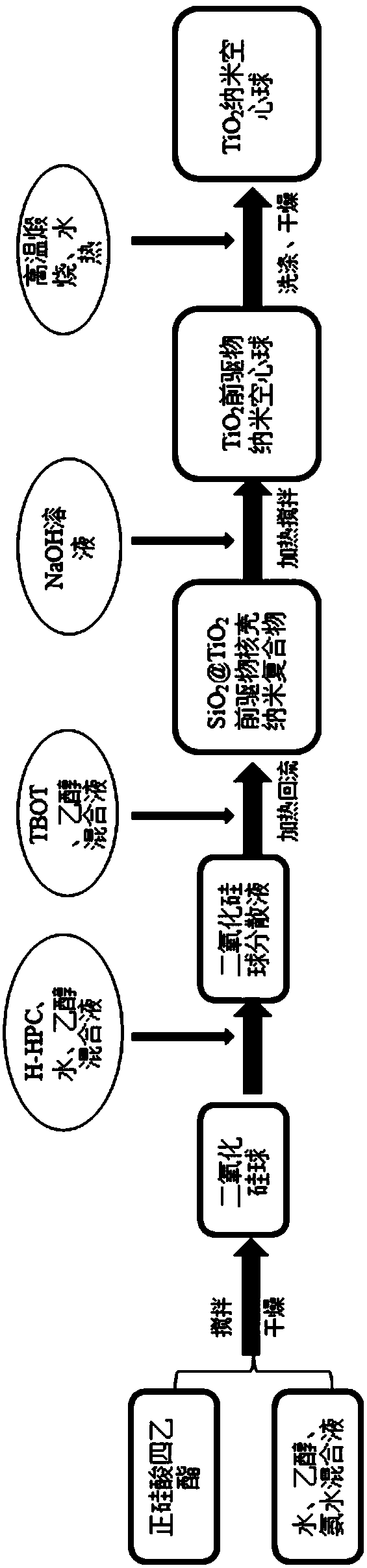

[0076] Such as figure 1 As shown, embodiment 1 proposes a kind of preparation method of titanium dioxide nano hollow sphere, specifically comprises the following steps:

[0077] 1. SiO2 2 ball preparation

[0078] 1.1. Mix water, ethanol and ammonia water according to the volume ratio of 5:33:1 to prepare solvent liquid I;

[0079] 1.2. Slowly add 0.6ml tetraethyl orthosilicate to the above solvent solution I, stir at room temperature for 8 hours, carry out hydrolysis reaction, then wash with ethanol several times, and dry at 70°C to obtain dispersed SiO 2 ball.

[0080] 2. TiO2 2 Precursor coating

[0081] 2.1. Mix water and ethanol according to the volume ratio of 1:120 to prepare solvent solution II;

[0082] 2.2. Add 100 mg of highly substituted hydroxypropyl cellulose dropwise into the above solvent solution II. After fully dissolving, add 0.10g of SiO prepared in step 1 2 The balls were fully dissolved to obtain a uniform mixed solution, which was recorded as sol...

Embodiment 2

[0095] Embodiment 2 proposes a kind of preparation method of titanium dioxide nanometer hollow sphere, specifically comprises the following steps:

[0096] 1. SiO2 2 ball preparation

[0097] 1.1. Mix water, ethanol and ammonia water according to the volume ratio of 5:36:1 to prepare solvent liquid I;

[0098]1.2. Slowly add 1.0ml tetraethyl orthosilicate to the above solvent solution I, stir at room temperature for 5 hours, carry out hydrolysis reaction, then wash with ethanol several times, and dry at 50°C to obtain dispersed SiO 2 ball.

[0099] 2. TiO2 2 Precursor coating

[0100] 2.1. Mix water and ethanol according to the volume ratio of 1:180 to prepare solvent liquid II;

[0101] 2.2. Add 60 mg of highly substituted hydroxypropyl cellulose dropwise into the above solvent solution II. After fully dissolving, add 0.20g of SiO prepared in step 1 2 The balls were fully dissolved to obtain a uniform mixed solution, which was recorded as solution A;

[0102] 2.3. Mix...

Embodiment 3

[0112] Embodiment 3 proposes a kind of preparation method of titanium dioxide nanometer hollow sphere, specifically comprises the following steps:

[0113] 1. SiO2 2 ball preparation

[0114] 1.1. Mix water, ethanol and ammonia water according to the volume ratio of 5:33:1 to prepare solvent liquid I;

[0115] 1.2. Slowly add 1.5ml tetraethyl orthosilicate to the above solvent solution I, stir at room temperature for 12 hours, carry out hydrolysis reaction, then wash with ethanol several times, and dry at 60°C to obtain dispersed SiO 2 ball.

[0116] 2. TiO2 2 Precursor coating

[0117] 2.1. Mix water and ethanol according to the volume ratio of 1:230 to prepare solvent liquid II;

[0118] 2.2. Add 140 mg of highly substituted hydroxypropyl cellulose dropwise into the above solvent solution II. After fully dissolving, add 0.3g of SiO prepared in step 1 2 The balls were fully dissolved to obtain a uniform mixed solution, which was recorded as solution A;

[0119] 2.3. M...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com