Preparation method of nano zinc oxide and nano zinc oxide

A nano-zinc oxide and zinc salt technology, applied in the direction of zinc oxide/zinc hydroxide, nanotechnology, nanotechnology, etc., can solve the problems of complex preparation process, long time-consuming, uncontrollable particle size of nano-zinc oxide, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0029] The embodiment of the present invention provides a kind of preparation method of nanometer zinc oxide, comprises the following steps:

[0030] (1) Zinc salt reaction solution and alkali source reaction solution are passed into respectively from the reaction solution inlet on both sides of the V-type microchannel reactor with a certain flow rate, so that it collides and mixes at the bottom of the V-type microchannel reactor, Obtain a suspension;

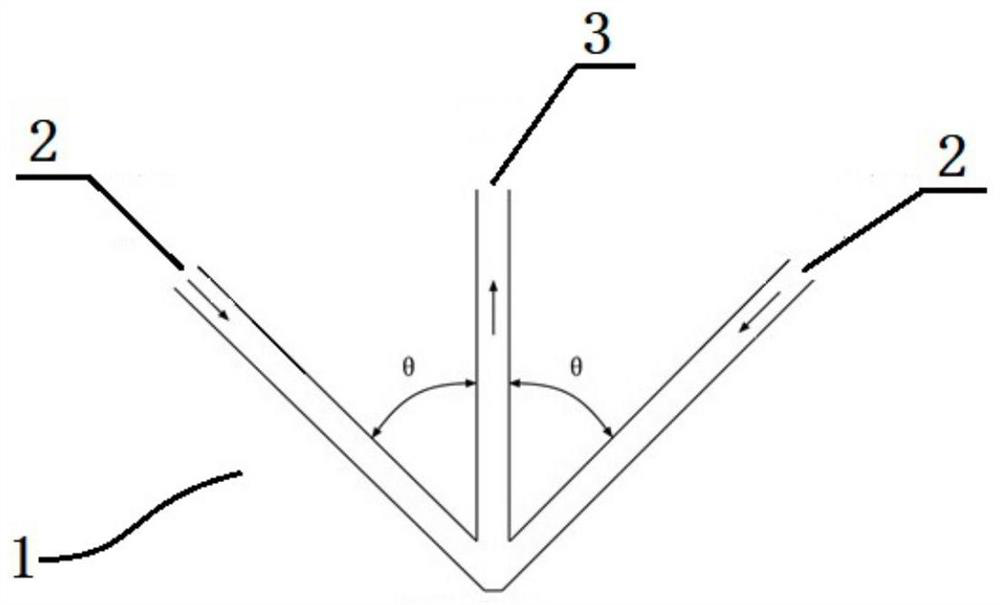

[0031]Wherein, the zinc salt includes one or more of zinc sulfate, zinc chloride, and zinc nitrate; the alkali source includes one of ammonium bicarbonate, sodium hydroxide, potassium hydroxide, sodium carbonate, and ammonium carbonate or more; preferably, the zinc salt reaction solution is a zinc sulfate aqueous solution with a concentration of 10-150g / L, and the alkali source reaction solution is an aqueous ammonium bicarbonate solution with a concentration of 11-165g / L; the flow rate is 0.1-1m / s; such as figure 1 As shown,...

Embodiment 1

[0039] In this embodiment, a V-shaped microchannel reactor made of polytetrafluoroethylene is used to prepare nano-zinc oxide, wherein the channel inner diameter of the V-shaped microchannel reactor is 0.4mm, and the angle between the two reaction solution inlet channels 2 and the outlet channel 3 Be respectively 10 °; The preparation method of the nano zinc oxide of the present embodiment comprises:

[0040] 1) preparation concentration is the zinc sulfate aqueous solution of 150g / L, the ammonium bicarbonate aqueous solution that concentration is 165g / L respectively as zinc salt reaction solution and alkali source reaction solution;

[0041] 2) The zinc salt reaction solution and the alkali source reaction solution are continuously introduced from the reaction solution inlets on both sides of the V-shaped microchannel reactor with a flow velocity of 0.8m / s, so that they collide and collide at the bottom of the V-type microchannel reactor. Mix to obtain a suspension;

[0042]...

Embodiment 2

[0045] In this embodiment, a stainless steel V-shaped microchannel reactor is used to prepare nano-zinc oxide, wherein the channel inner diameter of the V-shaped microchannel reactor is 4 mm, and the angles between the two reaction liquid inlet channels 2 and the outlet channels 3 are 90° respectively. The preparation method of the nano zinc oxide of the present embodiment comprises:

[0046] 1) preparation concentration is the zinc sulfate aqueous solution of 10g / L, the ammonium bicarbonate aqueous solution that concentration is 11g / L respectively as zinc salt reaction solution and alkali source reaction solution;

[0047] 2) The zinc salt reaction solution and the alkali source reaction solution are continuously introduced from the reaction solution inlets on both sides of the V-type microchannel reactor at a flow rate of 0.1m / s, so that they collide and collide at the bottom of the V-type microchannel reactor. Mix to obtain a suspension;

[0048] 3) Filtrating the suspensi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com