Method and device for preparing nanometer indium oxide through electrolysis

A technology for preparing nanometer indium oxide and electrolyte, which is applied in the field of powder material preparation, can solve the problems of a large amount of nitrogen-containing wastewater, difficult to remove halogen elements, and the cost of wastewater treatment increases, and achieves the best specific surface area, small particle size, and high particle size. well shaped effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

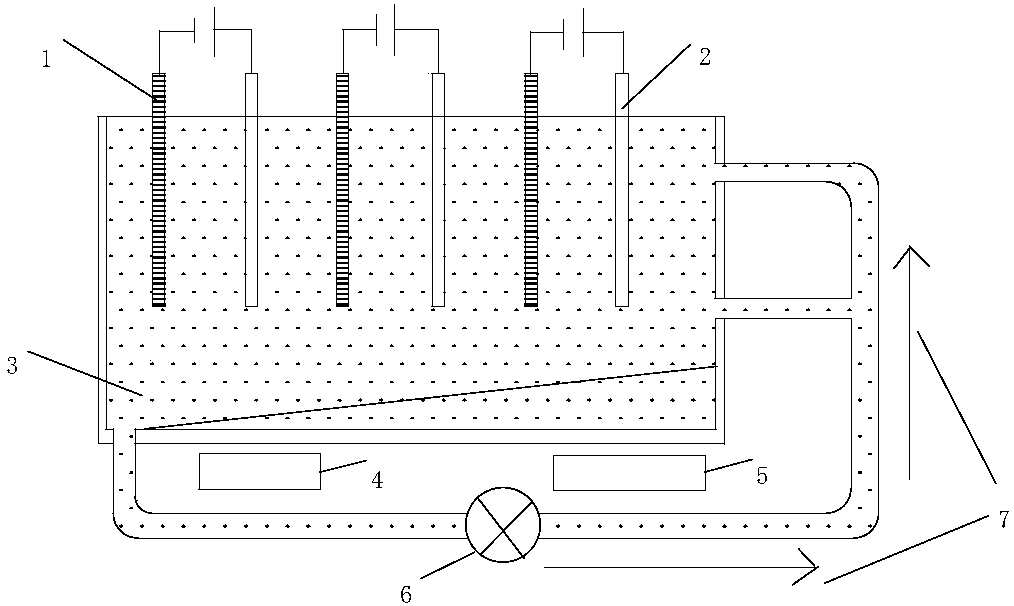

[0048] In Example 1, the length, width and height of the electrolytic tank were 50, 30 and 50 cm respectively, the distance between the cathode and the anode was 5 cm, and a 20-degree slope was designed at the bottom of the electrolytic tank to facilitate the collection and circulation of products. There are holes on the bottom and sides of the tank, and the function of the circulation pump is used to realize the circulation of the electrolyte and prevent the accumulation of indium hydroxide particles.

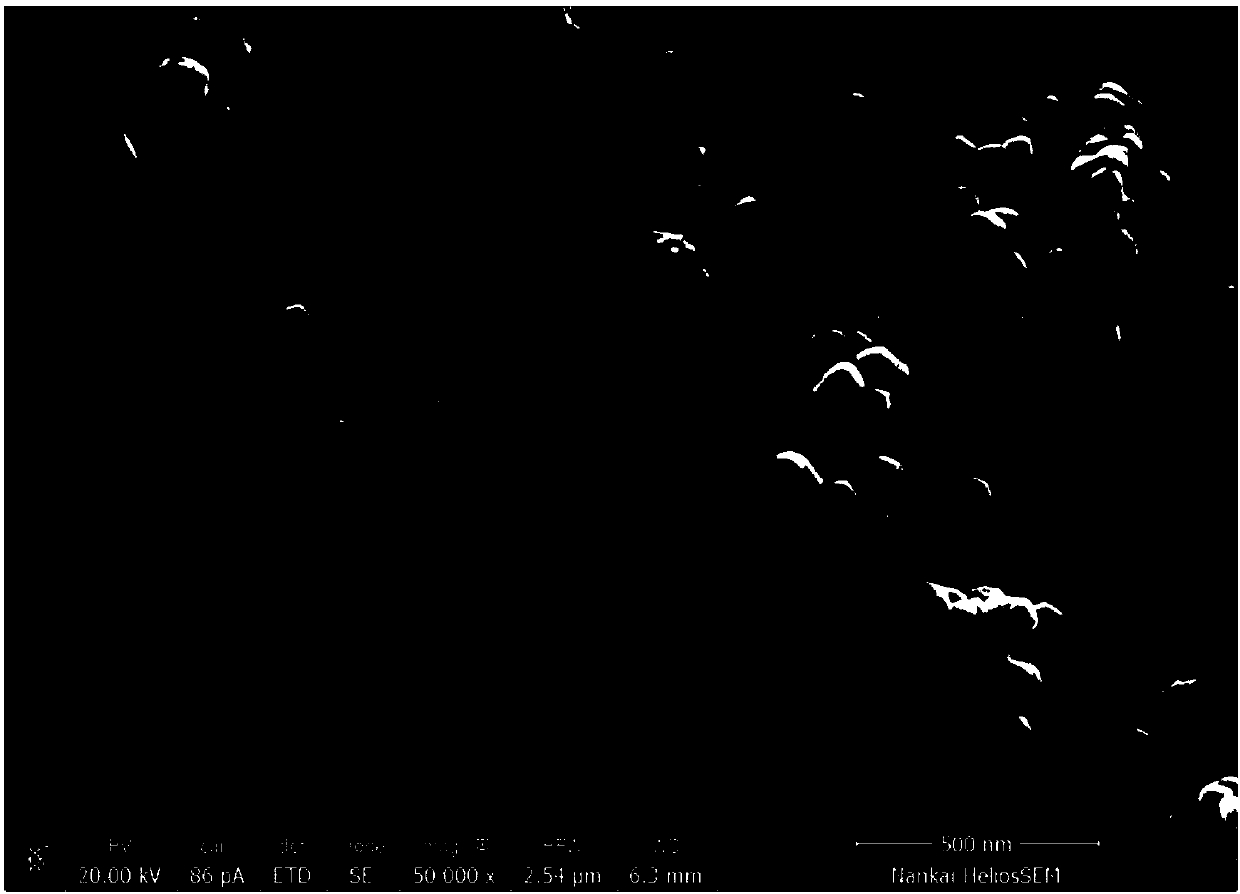

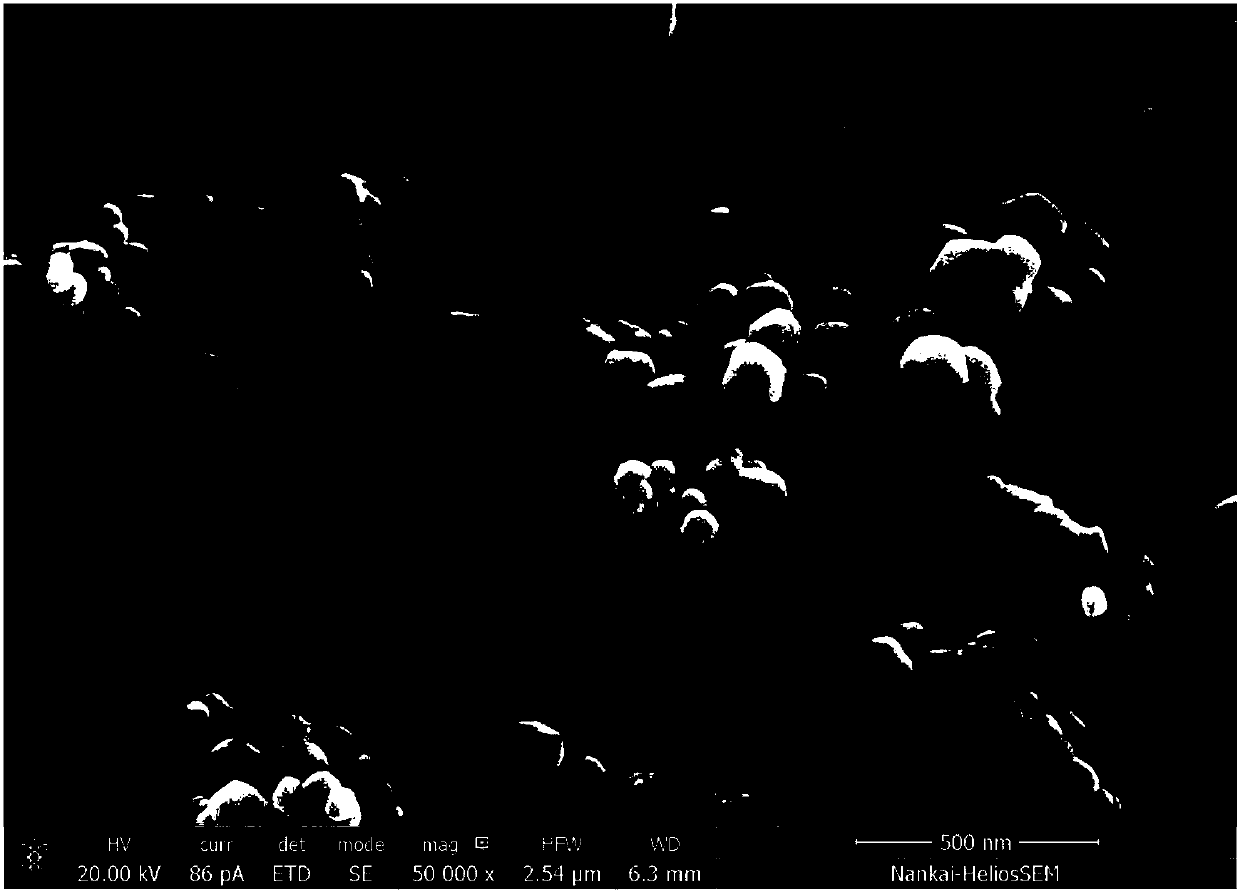

[0049] The concentration of the electrolyte is set to 2mol / L, the pH value of the electrolyte is adjusted to 4.8, the temperature of the electrolyte is maintained at about 25°C, and the current density of the electrolyte is set to 15A / dm 2 , when the concentration of the electrolysis product is 10%, the electrolysis is stopped, the indium hydroxide powder generated by electrolysis is collected, and the indium oxide powder is obtained through subsequent drying and calcination. ...

Embodiment 2

[0053] In Embodiment 2, the device of the electrolytic cell is exactly the same as that in Embodiment 1, except that relevant electrolysis process parameters are adjusted accordingly.

[0054] The concentration of the electrolyte is set to 1mol / L, the pH of the electrolyte is adjusted to 4.8, the temperature of the electrolyte is maintained at about 25°C, and the current density of the electrolyte is set to 15A / dm 2 , when the concentration of the electrolysis product is 10%, the electrolysis is stopped, the indium hydroxide powder generated by electrolysis is collected, and the indium oxide powder is obtained through subsequent drying and calcination.

[0055] The indium oxide powder prepared above was tested, and the results are shown in Table 2.

[0056] The performance test result of the indium oxide powder that table 2 embodiment 2 prepares

[0057] Measurement items

Embodiment 3

[0059] In Embodiment 3, the device of the electrolytic cell is exactly the same as that in Embodiment 1, except that relevant electrolysis process parameters are adjusted accordingly.

[0060] The concentration of the electrolyte is set to 0.5mol / L, the pH value of the electrolyte is adjusted to 4.8, the temperature of the electrolyte is maintained at about 25°C, and the current density of the electrolyte is set to 15A / dm 2 , when the concentration of the electrolysis product is 10%, the electrolysis is stopped, the indium hydroxide powder generated by electrolysis is collected, and the indium oxide powder is obtained through subsequent drying and calcination.

[0061] The indium oxide powder prepared above was tested, and the results are shown in Table 3.

[0062] The performance test result of the indium oxide powder that table 3 embodiment 3 prepares

[0063] Measurement items

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com