Method for preparing copper alloy powder by means of plasma rotating electrode

A technology of rotating electrodes and copper alloys, applied in the direction of additive processing, etc., can solve the problems of low powder sphericity, poor fluidity, and many satellites, and achieve the effects of high powder quality, less gas inclusions, and narrow particle size range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1)

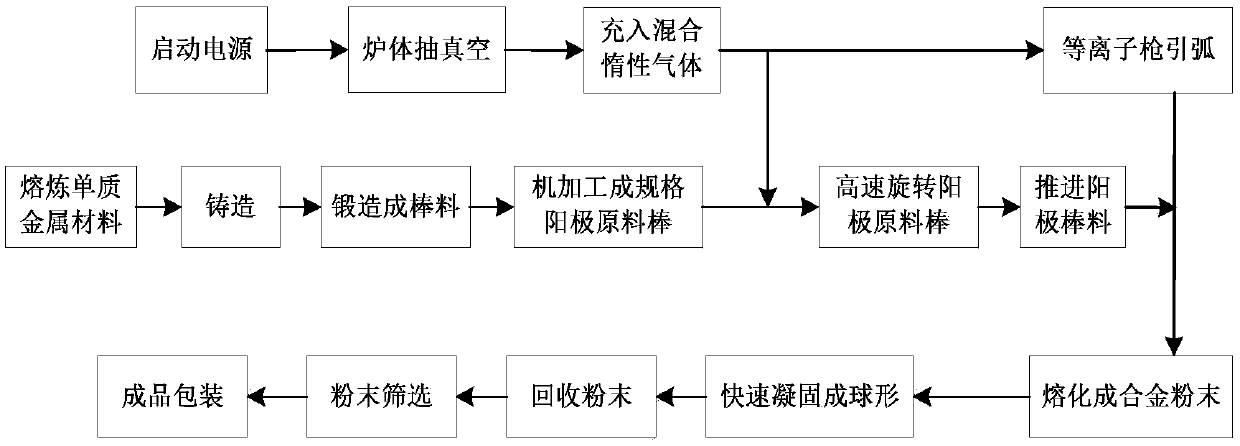

[0026] see figure 1 , the method for preparing copper alloy powder by the plasma rotating electrode of the present embodiment comprises the following steps:

[0027] ①According to the composition (mass fraction) of the copper alloy powder to be prepared (mass fraction) Al 9% to 13%, Ni 12% to 18%, Fe 8% to 12%, and the balance is Cu to carry out the batching (in this embodiment, it is Al 11.9%, Ni 15%, Fe 10%, the balance is Cu).

[0028] The specific composition of the copper alloy given here is only an example, and the method of the present invention can also prepare copper alloy powders with other compositions.

[0029] Vacuum induction furnace is used to melt the ingot and then forge it, and then machine it into a forged alloy bar with a dense structure. The specifications of the alloy bar are 40-60mm in diameter (50mm in this embodiment) and 400-900mm (400mm in this embodiment), surface roughness ≤ 3.2µm (0.8µm in this embodiment), relative density of the alloy bar ≥ 95...

Embodiment 2)

[0040] The plasma rotating electrode of the present embodiment prepares the method for copper alloy powder all the other and embodiment 1 is identical, difference is:

[0041]③ Turn on the plasma rotating electrode powder making equipment, set the speed of the alloy rod to 20000r / min, the current and voltage of the plasma gun are: current 2000A, voltage 110V, the short distance between the gun and the bar is 3mm, and the feed speed is less than 1mm / s.

[0042] After the powder of this example is sieved through a 325-mesh sieve, the powder yield of 45-105 μm is 53%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| surface roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com