Patents

Literature

47 results about "Conducting zone" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

The conducting zone of the respiratory system is made up of the nose, pharynx, larynx, trachea, bronchi, bronchioles, and terminal bronchioles; their function is to filter, warm, and moisten air and conduct it into the lungs. It consists of a series of interconnecting cavities and tubes both outside and within the lungs. It is composed of the 1st through the 16th division of the respiratory tract. The conducting zone is thus most of the respiratory tract; it is the portion of the airway that conducts gases, but excludes the portion that exchanges gases. Thus, conducting zone + respiratory zone = respiratory tract

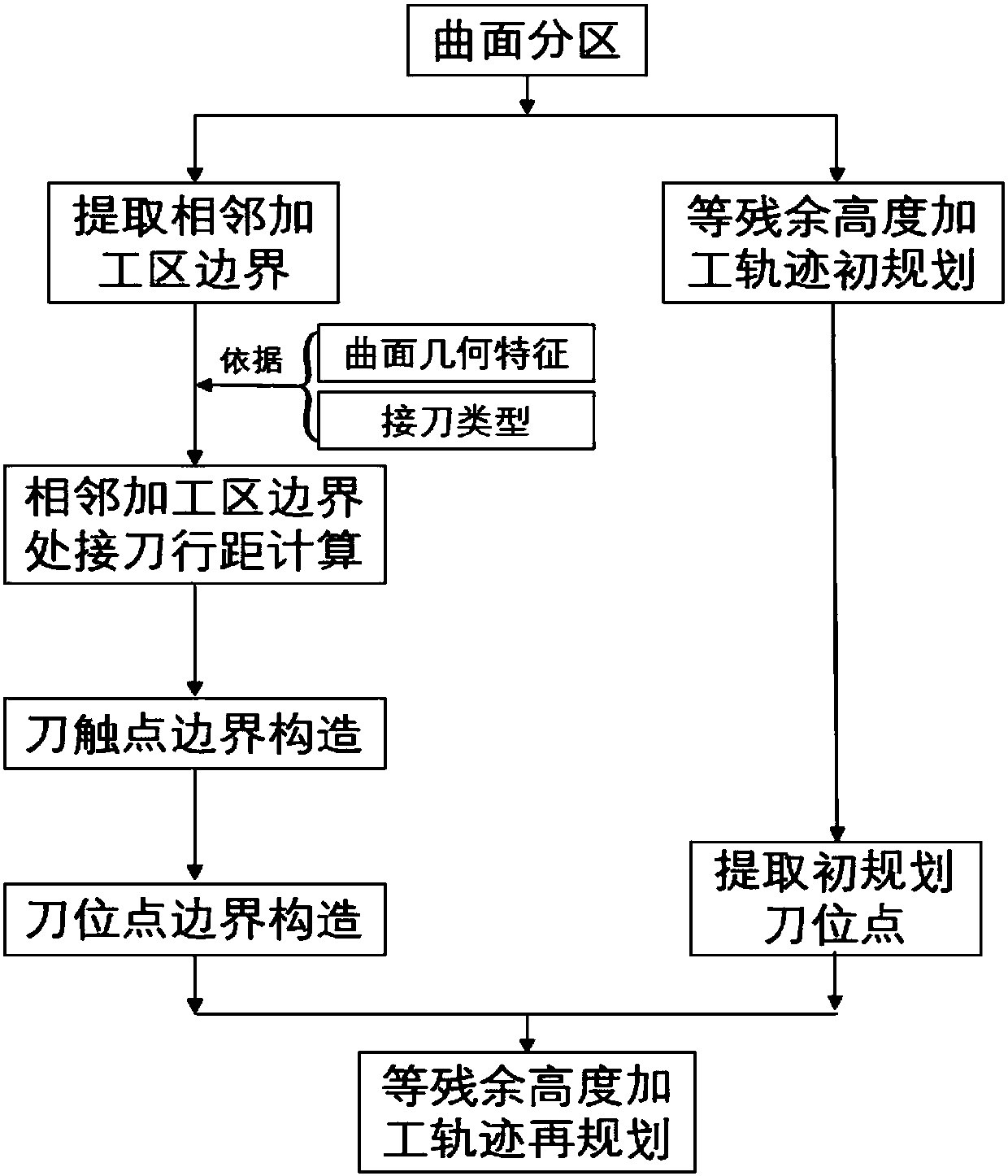

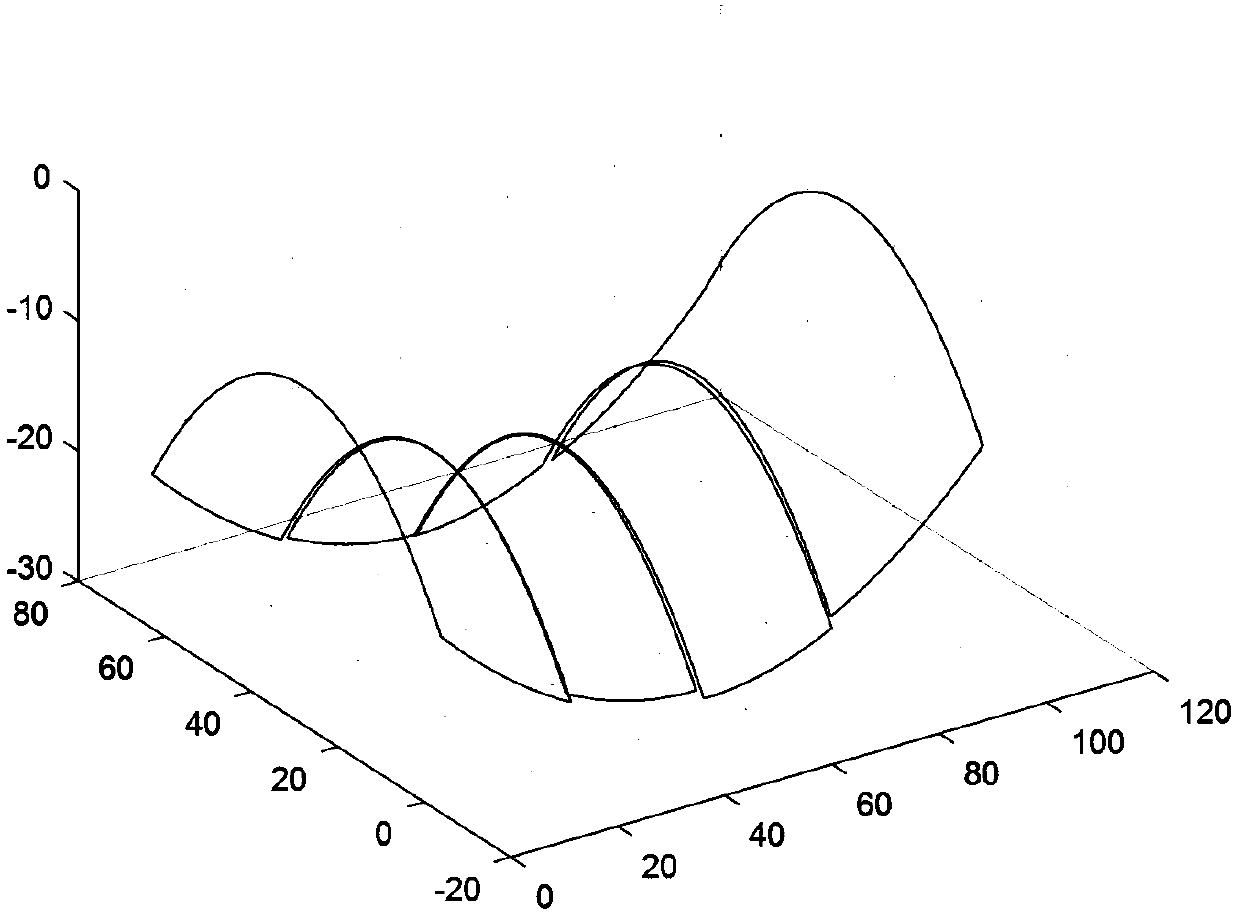

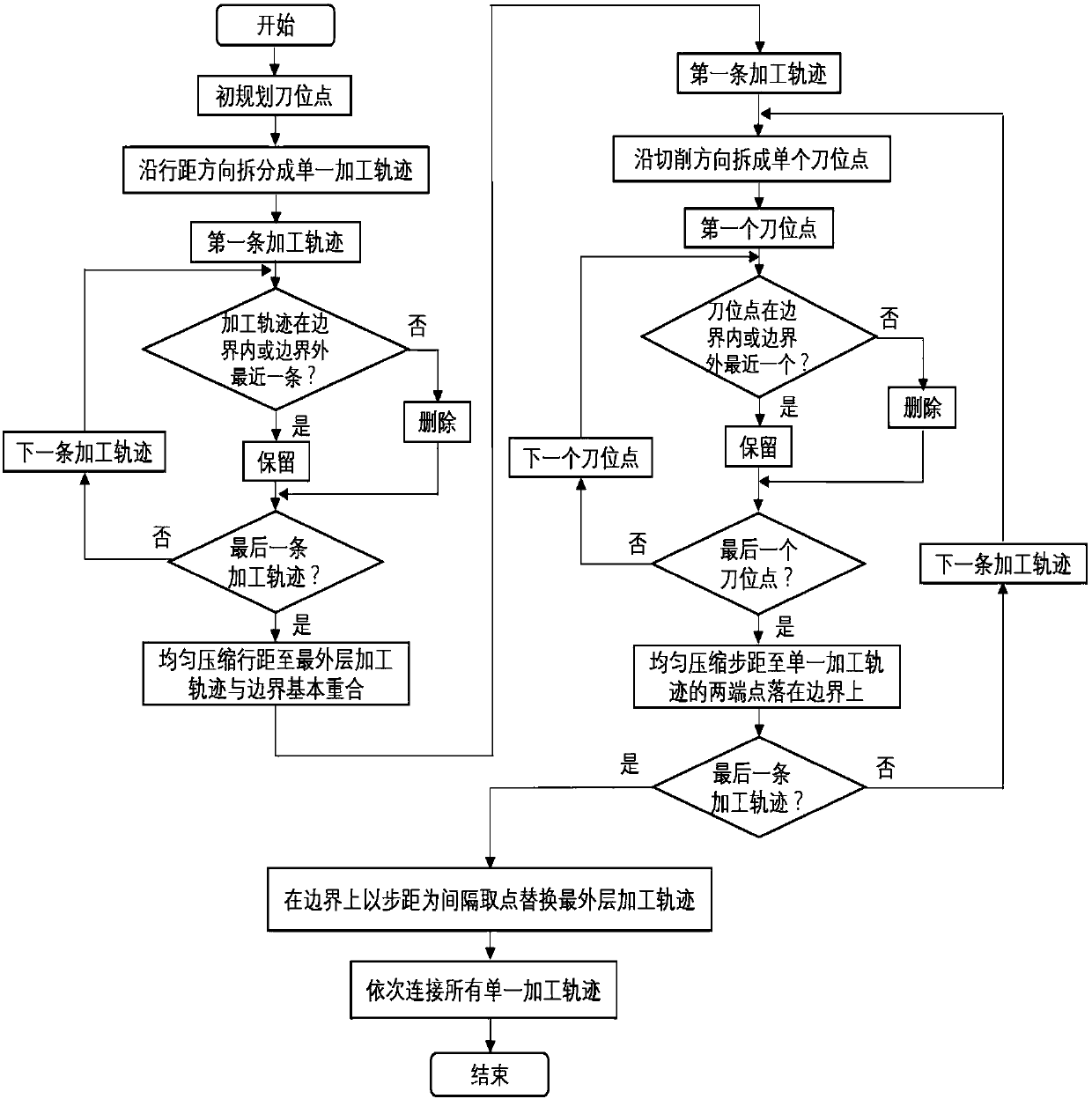

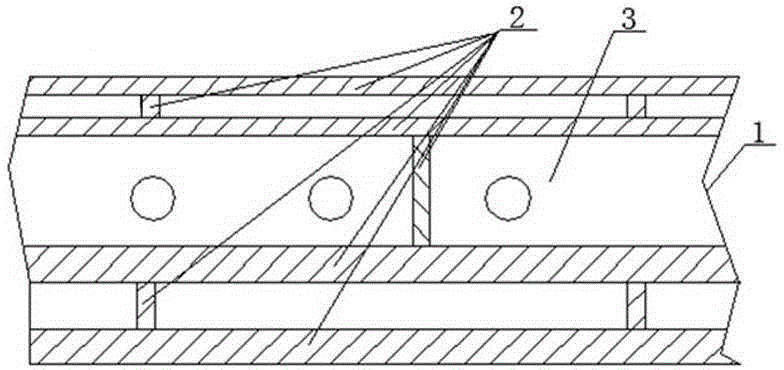

Track planning method of turning curved surface zone having equal scallop-height into cutter processing

ActiveCN107562013AHigh-precision and efficient processingReduce the knife markNumerical controlPoint boundaryEngineering

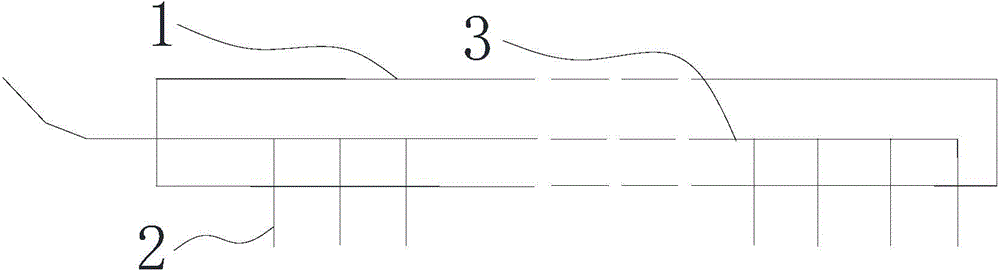

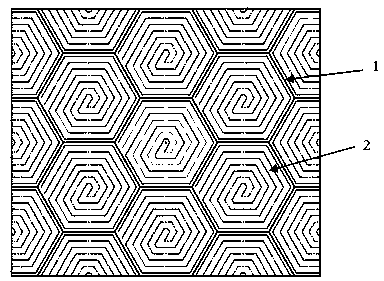

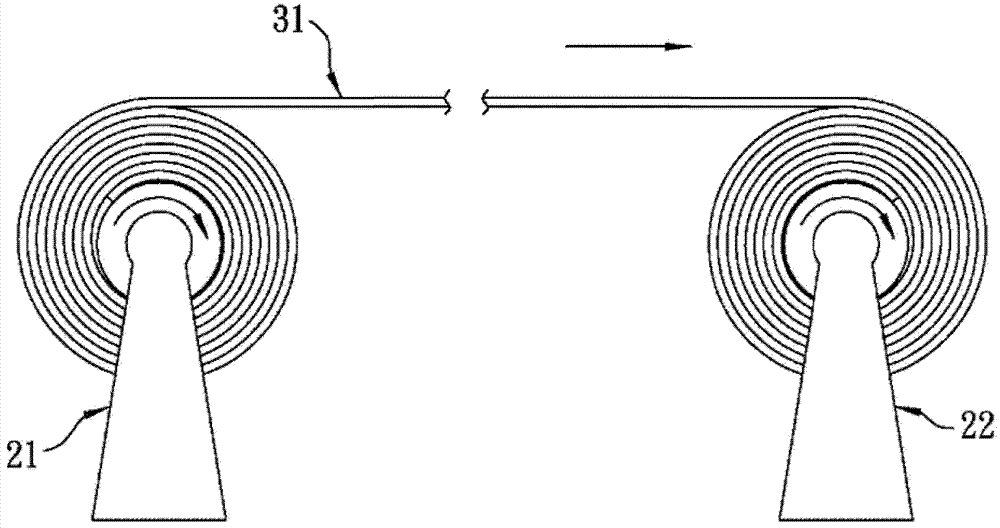

The invention discloses a track planning method of turning curved surface zone having equal scallop-height into a cutter processing, which belongs to the technical field of highly-precise and highly-efficient milling and processing of complicated curved surface parts. The track planning method of turning curved surface zone having equal scallop-height into a cutter processing comprises the steps of conducting zone partitioning on the curved surface based on the geometric features and processing requirement of the curved surface; determining the boundary of adjacent processing zones; conductingthe initial plan of equal scallop-height processing track on different processing zones. Through analyzing the geometric features of boundary, the geodesic radius of curvature and the cutter space along the space direction can be calculated, and the cutter contact point and cutter position point corresponding to any points on the boundary of adjacent processing zones can be resolved. The cutter position points form the cutter point boundary through interpolation and fitting. The invention is advantageous in that planning can be conducted with the cutter position point being the constraint, and it can be guaranteed that the cutter position point falls in the cutter position point boundary and on the boundary; the cutter position point can be adjusted, so that the error brought by planningcan be homogenized; the method is suitable for turning the complicated curved surface into cutter processing, and gear mark can be reduced, and processing quality can be improved.

Owner:DALIAN UNIV OF TECH

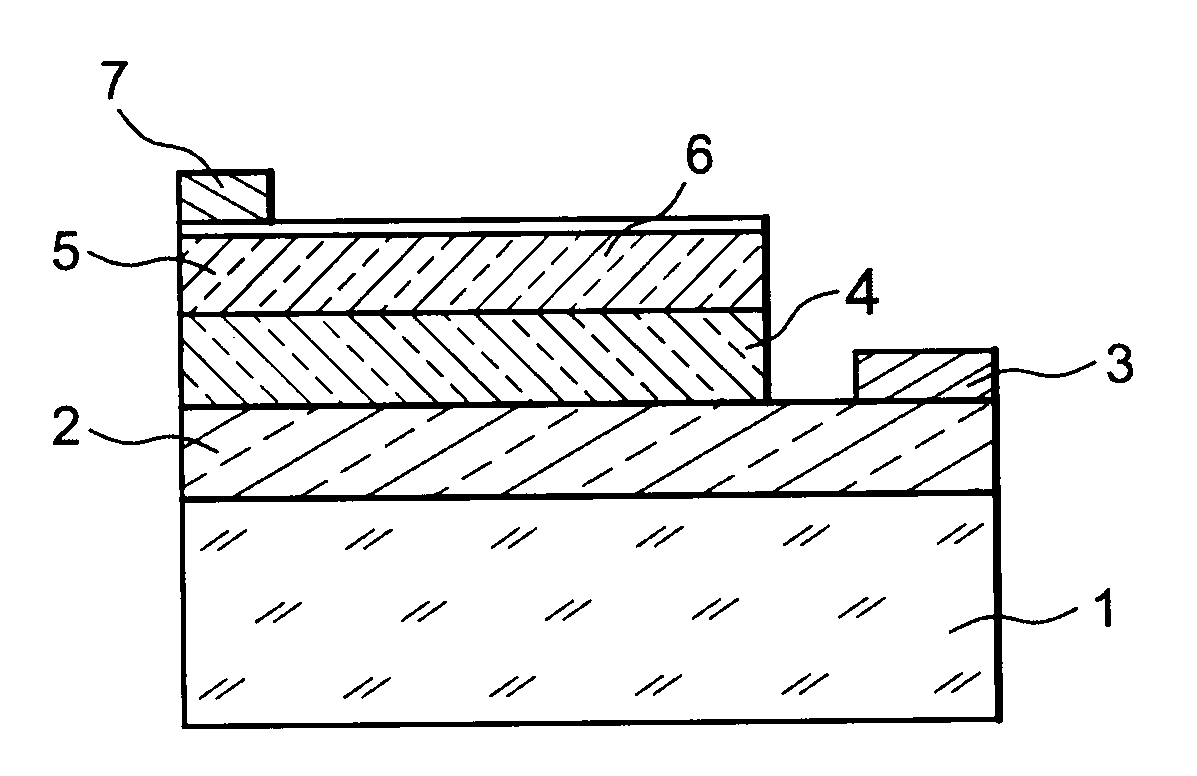

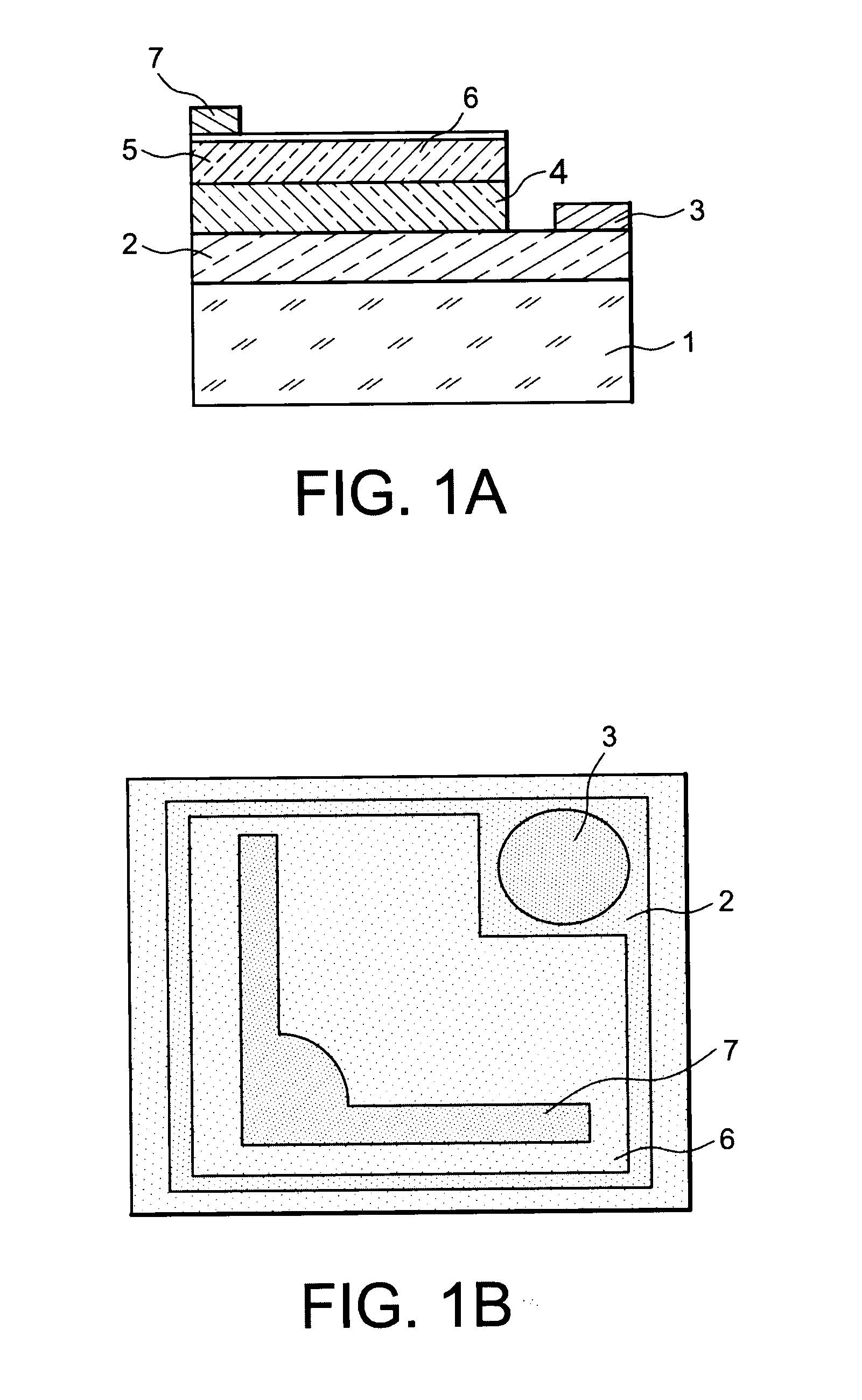

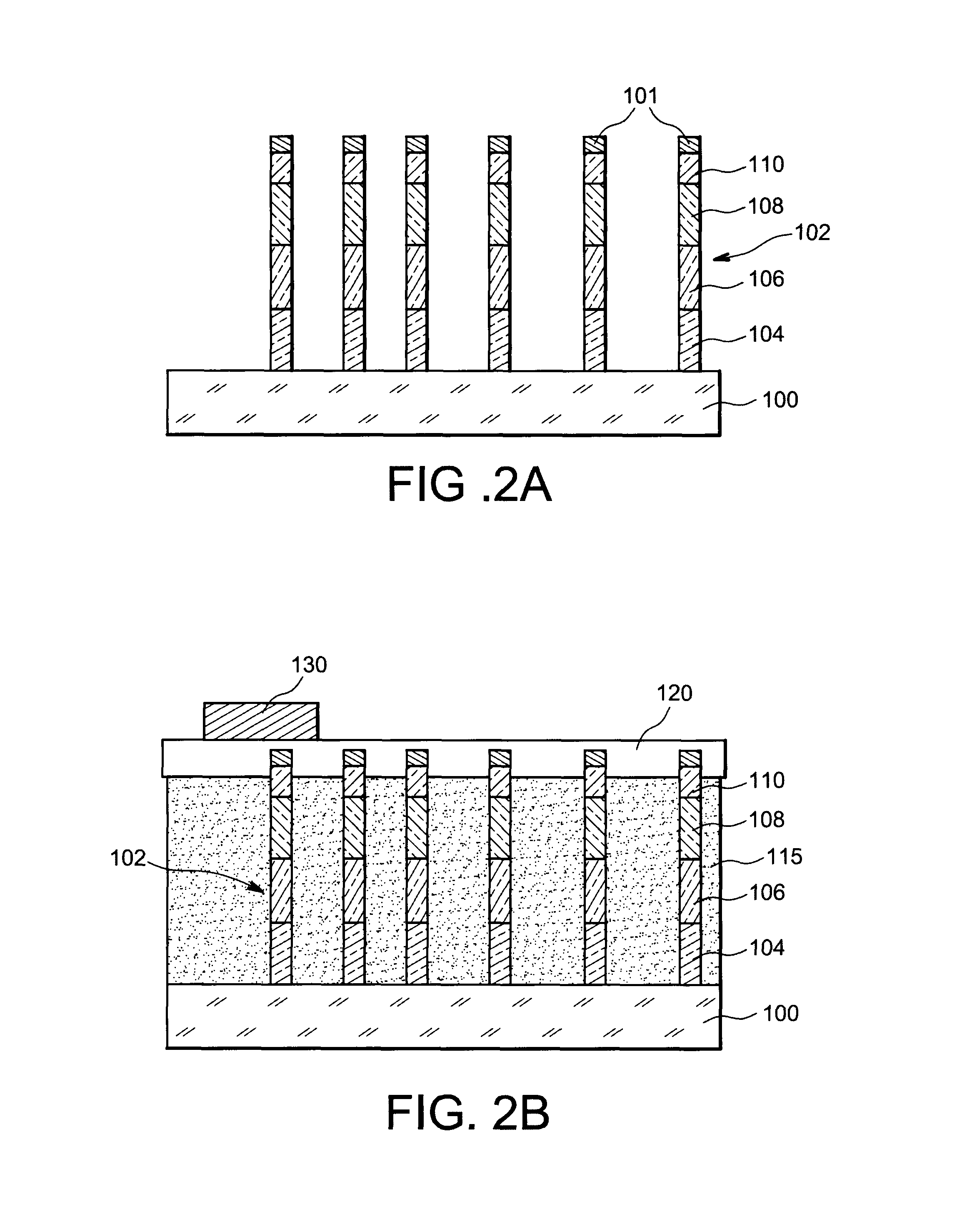

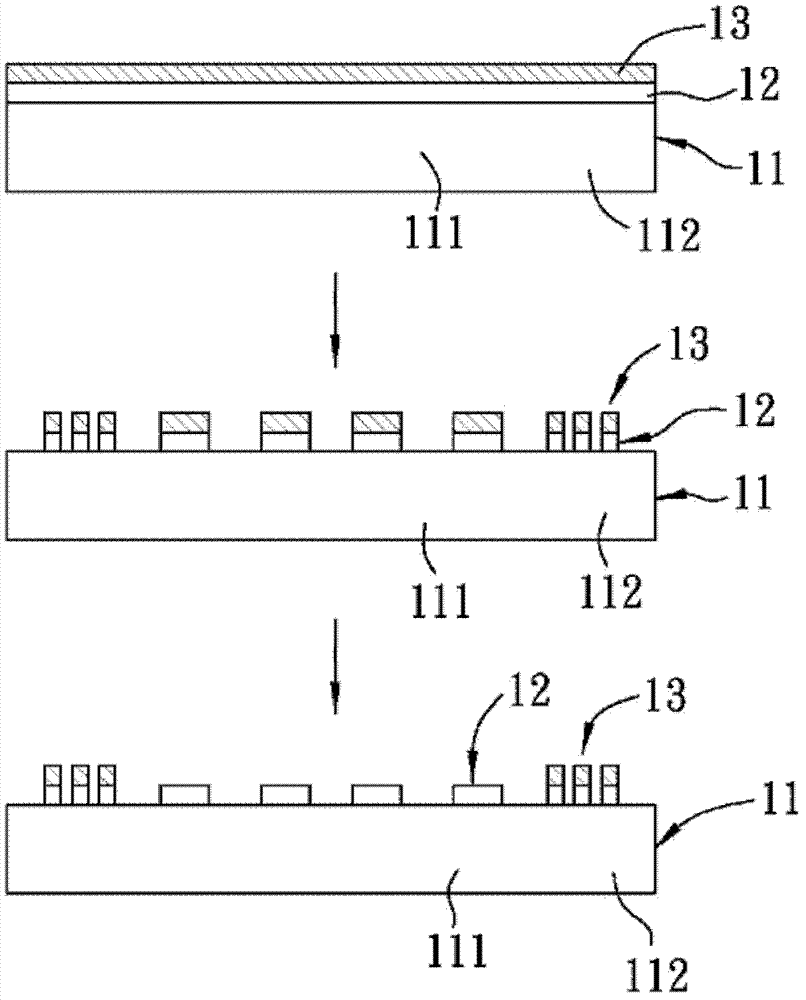

Process of making a microelectronic light-emitting device on semi-conducting nanowire formed on a metallic substrate

ActiveUS20090246901A1Polycrystalline material growthSolid-state devicesMaterial DesignSemiconductor materials

A process of making a microelectronic light-emitting device, including: a) growth on a metallic support of multiple wires based on one or more semi-conducting materials designed to emit radiant light, and b) formation of at least one electrical conducting zone of contact on at least one of the wires.

Owner:CENT NAT DE LA RECHERCHE SCI

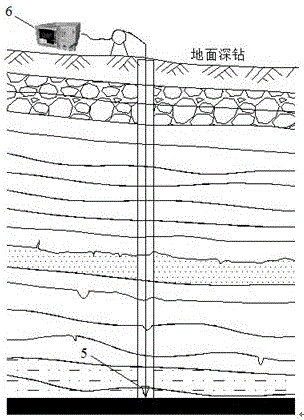

Wellhole multi-parameter searching method for rock deformation and damage features

PendingCN106772678AEnhanced couplingRich dataWater resource assessmentGeological measurementsDrill holeConducting zone

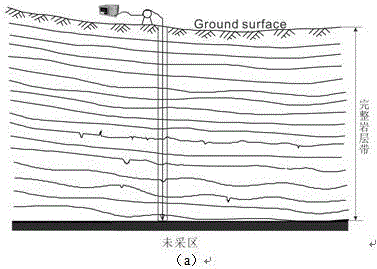

The invention discloses a wellhole multi-parameter searching method for rock deformation and damage features. By a BOTDR distributed optical fiber single-end testing mode, total hole depth is deeply drilled to acquire strain data, and different depth positions of an overlying strata after mining of a working face and deformation features of extrusion, tension, shearing and the like, which are shown by a geologic body, of different rock strata in a deformation process can be reflected. Effective deformation of a linear test total drill hole controlled depth stratum is formed, and the shortcoming that data are missing easily by original point type data acquisition is overcome. The test method is clear and visible in test, and has high accuracy and precision; and the heights of a caving zone and a water conducted zone can be judged accurately. By electric field response analysis of a parallel electrical-method test technology, qualitative and quantitative accurate judgment can be realized, test accuracy is improved effectively, and other interference factors are controlled.

Owner:ANHUI UNIV OF SCI & TECH

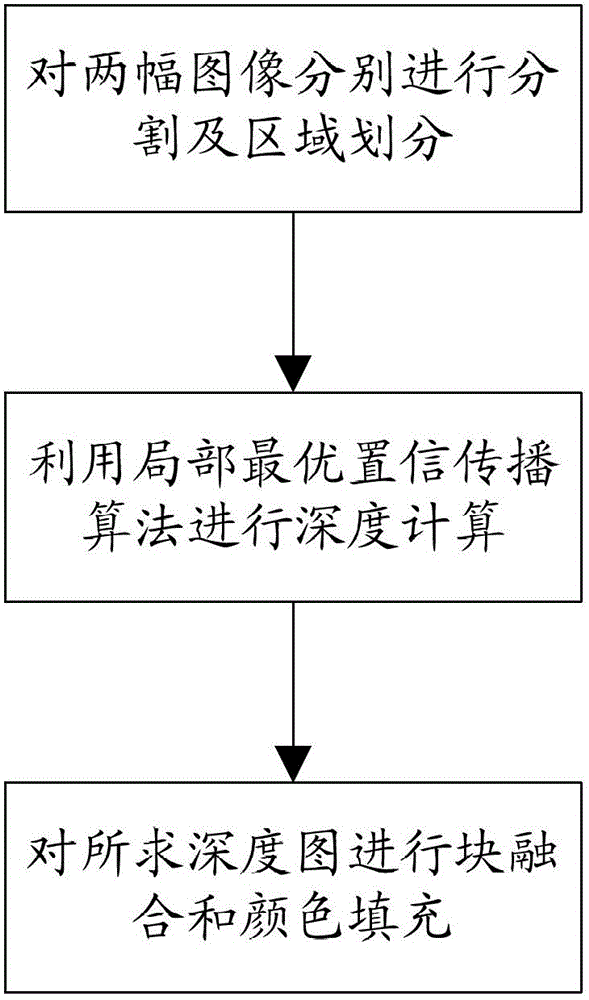

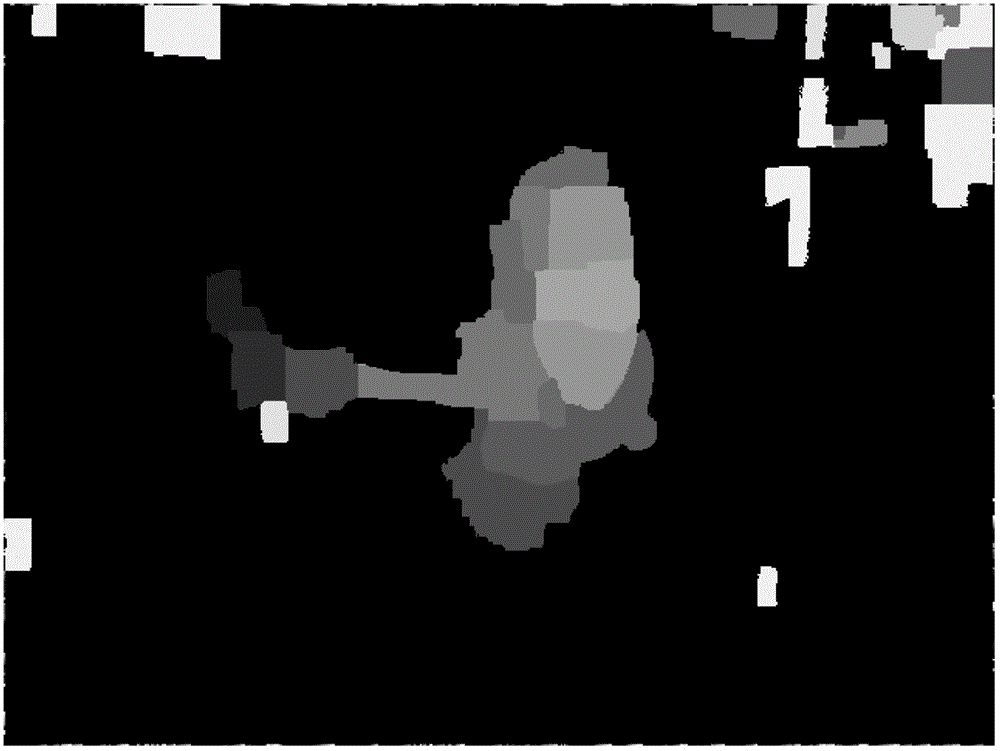

Local optimum belief propagation algorithm-based binocular video depth map solution method

ActiveCN102750694AAcquisition speed is fastSpread does not affectImage analysisParallaxPattern recognition

The invention provides a local optimum belief propagation algorithm-based binocular video depth map solution method. The method comprises the steps as follows: conducting partition and region division to two images; carrying out depth calculation by utilizing the local optimum belief propagation algorithm, processing different regions and different message values, wherein the message values are pixel visual difference information; and conducting zone fusion and color filing to the depth map. The method can conduct separate propagation in different regions by the improved belief propagation algorithm-based message propagation mode, and improve the depth map acquisition speed by changing the message propagation range and establishing the relation among the remote pixels, does not influence the propagation of a correct message by conducting separate processing to a shielded part, and greatly reduces the zone number and leads the optical parallax between zones to be more smooth by merging the small divided zones and conducting overall color filling to the object.

Owner:TSINGHUA UNIV

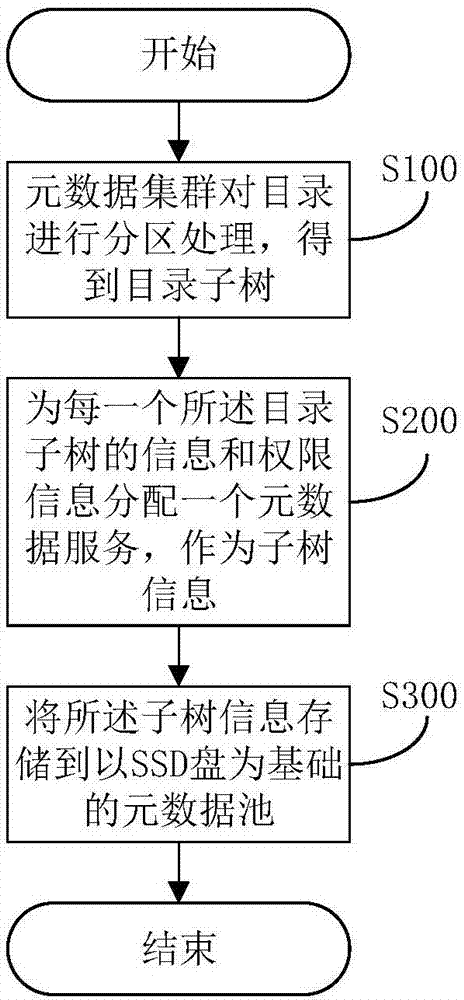

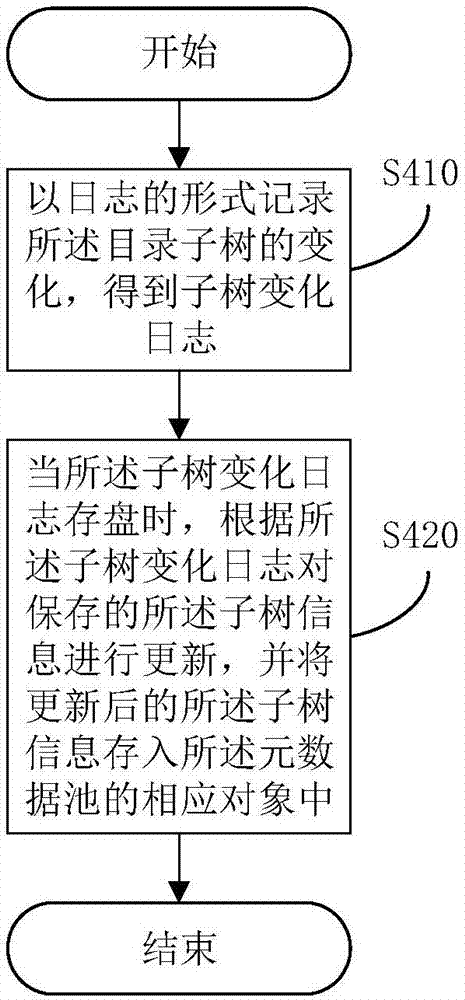

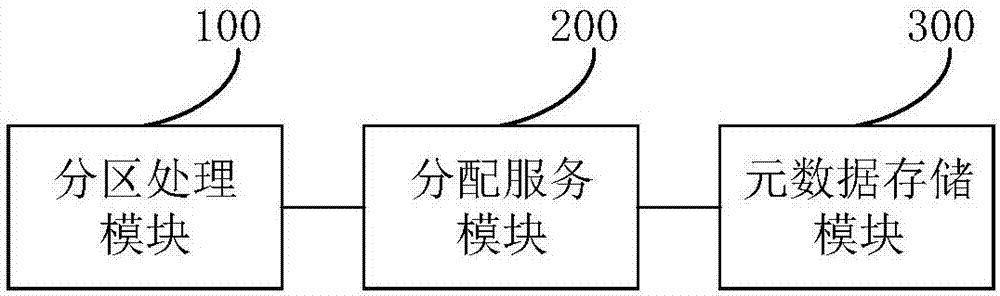

Distributed file system subtree storage method and device

InactiveCN107239569AEasy to operateImprove performanceSpecial data processing applicationsDistributed File SystemFile system

The invention discloses a distributed file system subtree storage method. The method comprises the steps that a meta-data cluster conducts zoning processing on an catalogue, and a catalogue subtree is obtained; a meta-data service is distributed for information of the catalogue subtree and authority information corresponding to the catalogue subtree respectively, and the meta-data services are used as subtree information; the subtree information is stored into a meta-data pool on the basis of an SSD disk. The SSD disk is used as a magnetic disk of the meta-data, the operating property of a file system for the meta-data can be accelerated by using the quick-reading characteristic of the SSD. Due to the fact that the operating speed of a user for the file is determined by the operating speed of the meta-data, the property of the whole file system is also improved. The invention further discloses a distributed file system subtree storage device, and the device has above advantages.

Owner:ZHENGZHOU YUNHAI INFORMATION TECH CO LTD

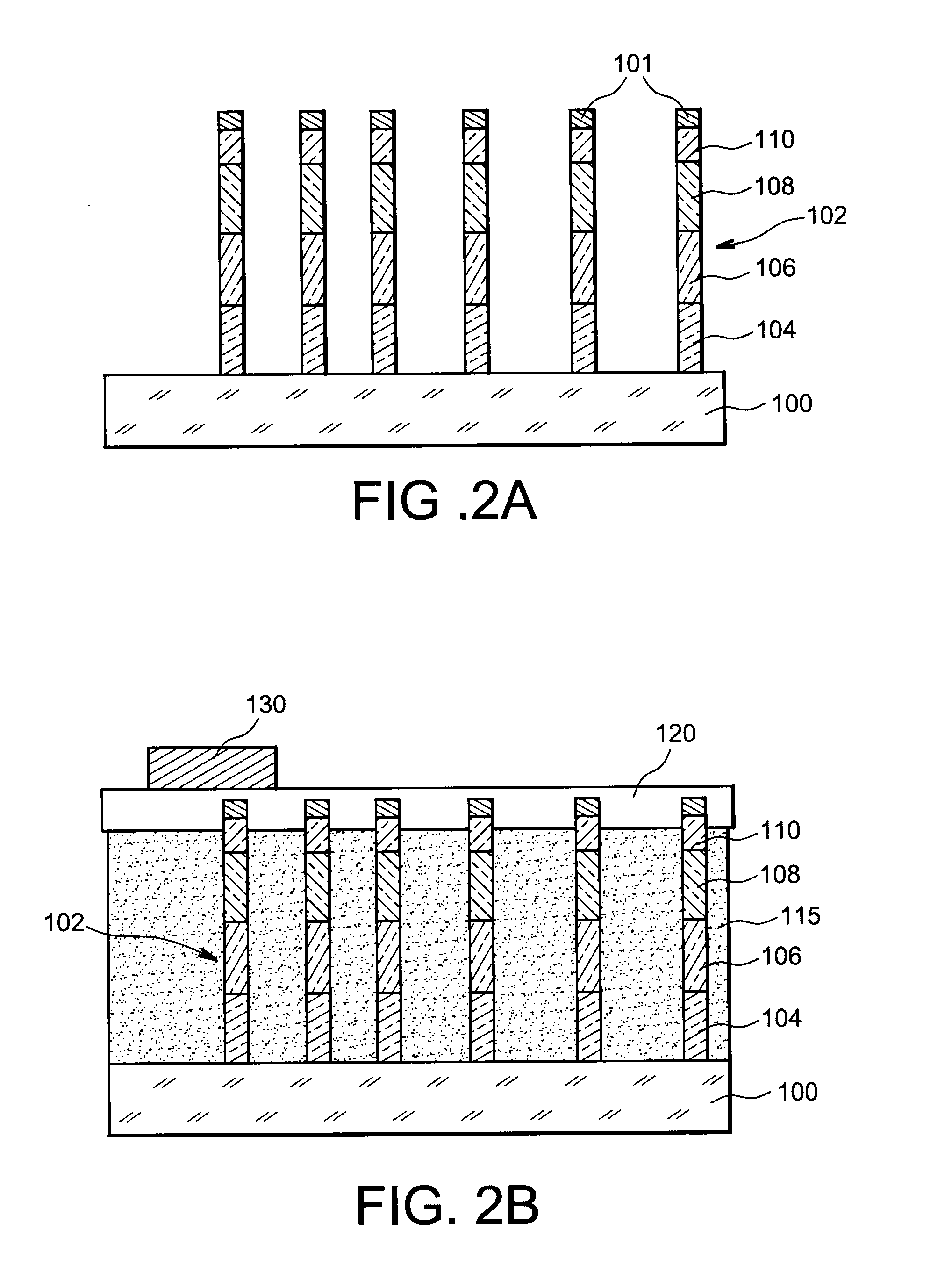

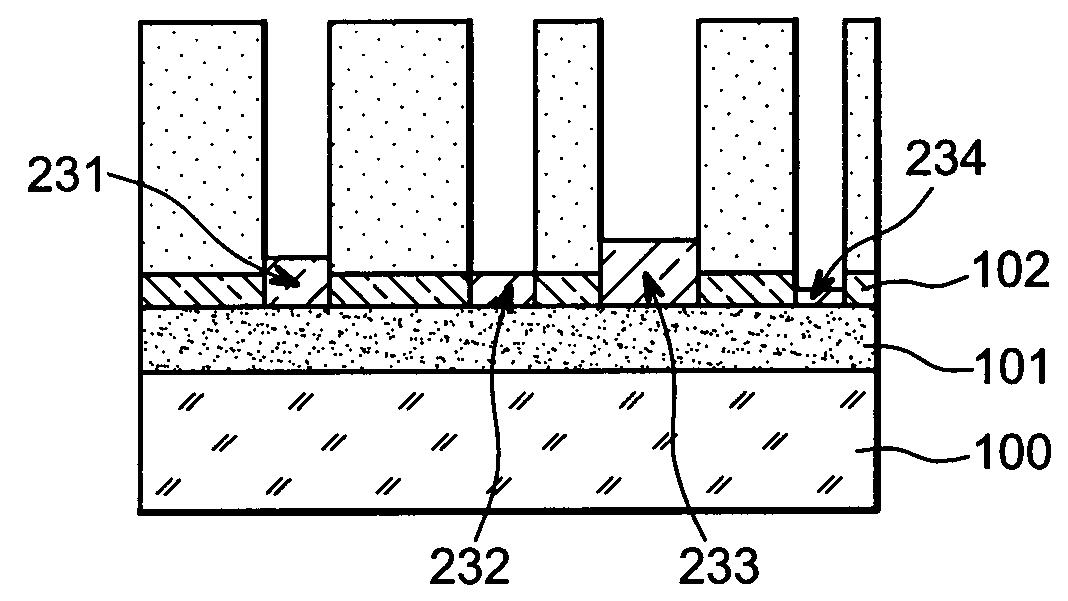

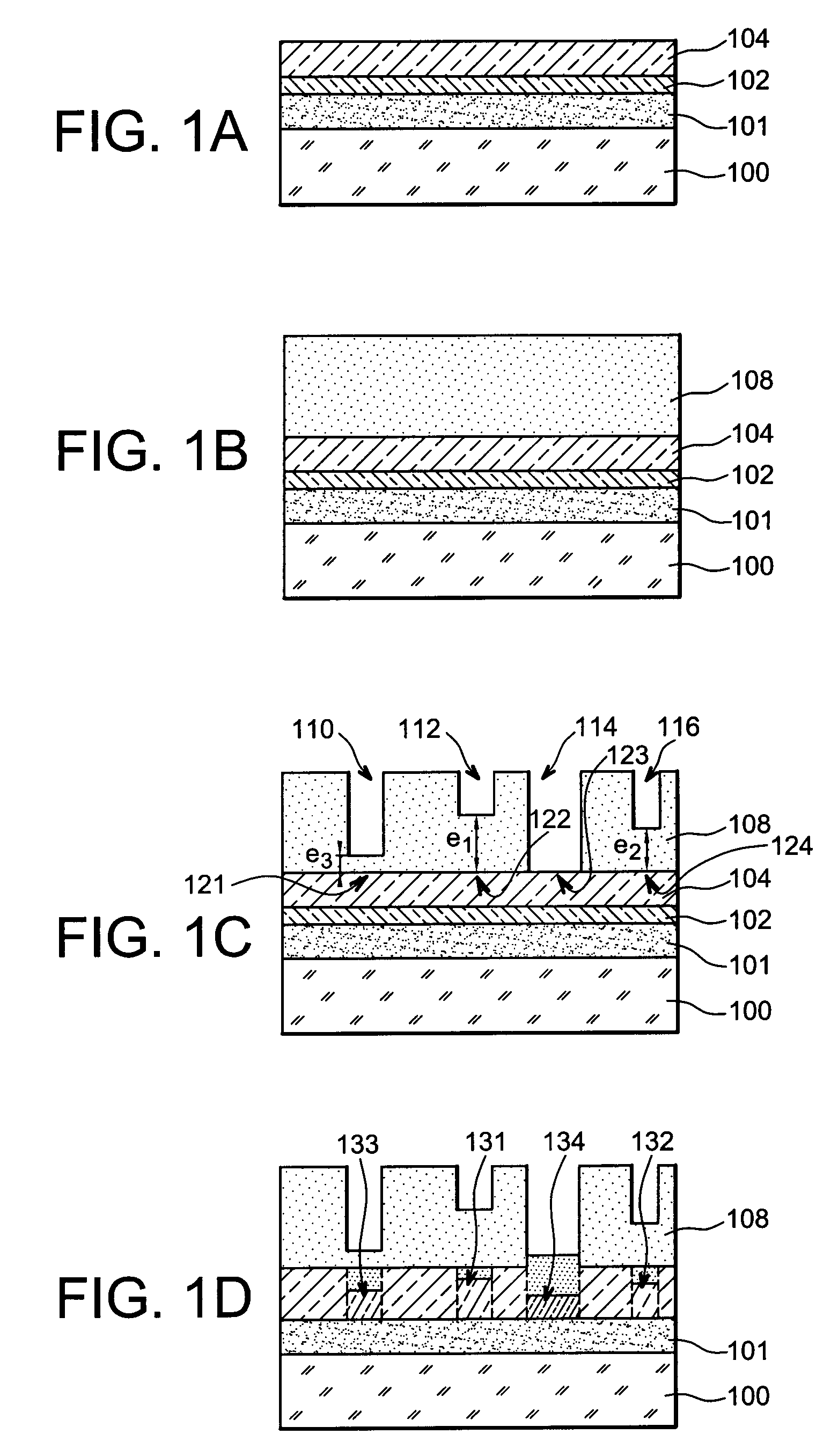

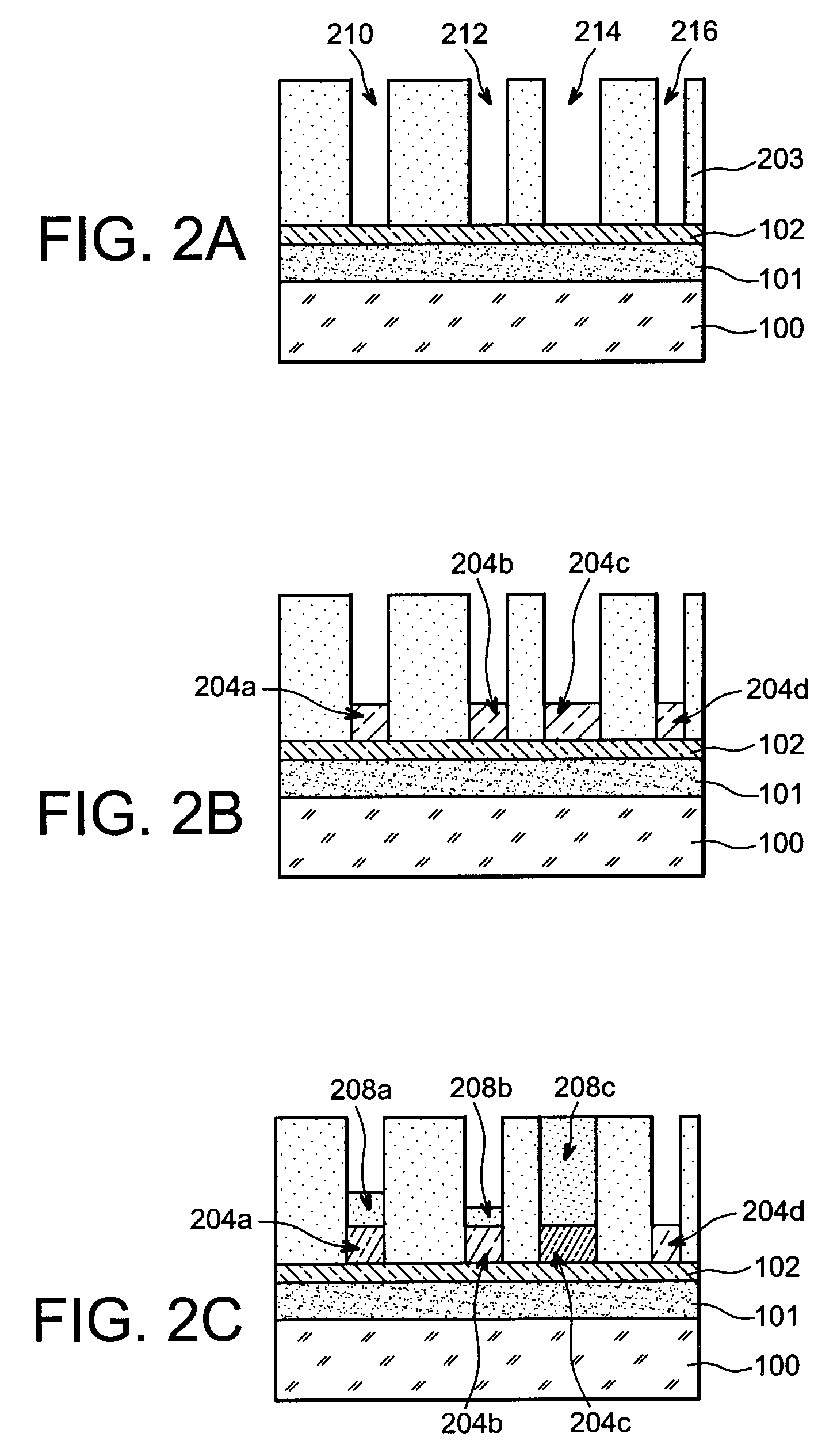

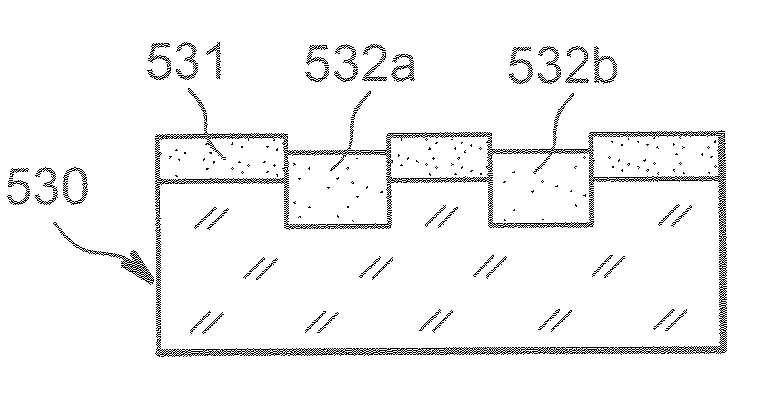

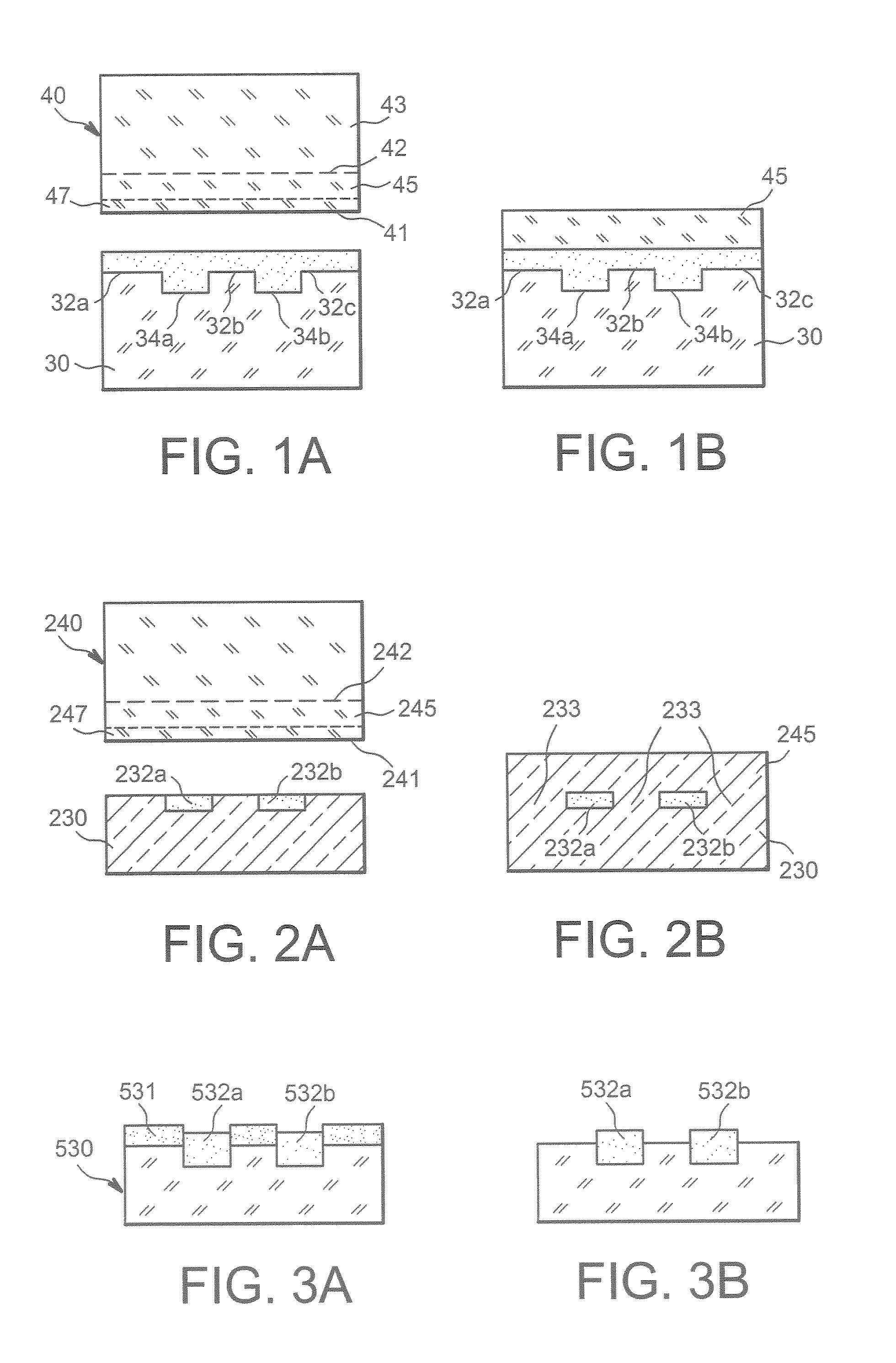

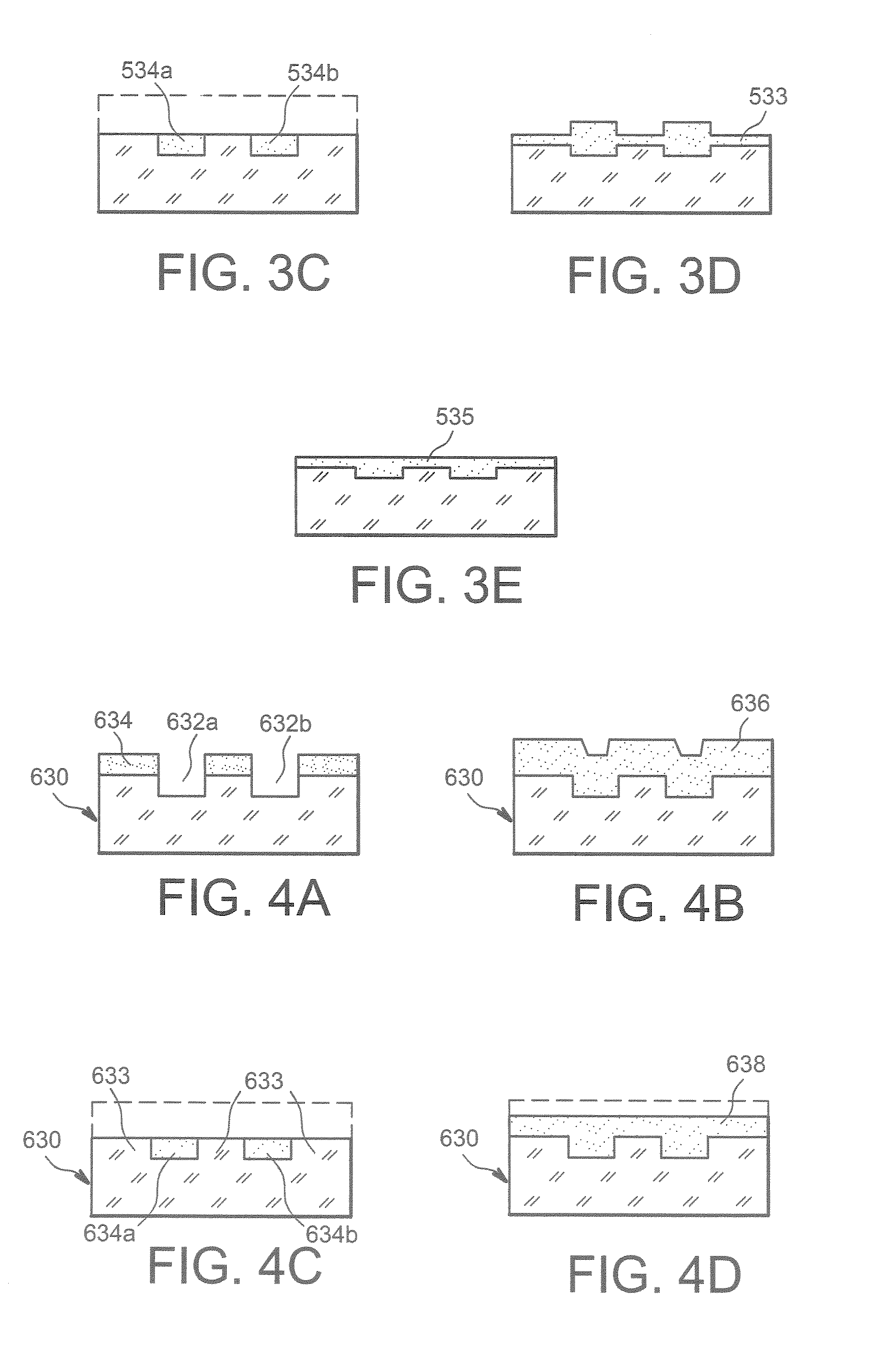

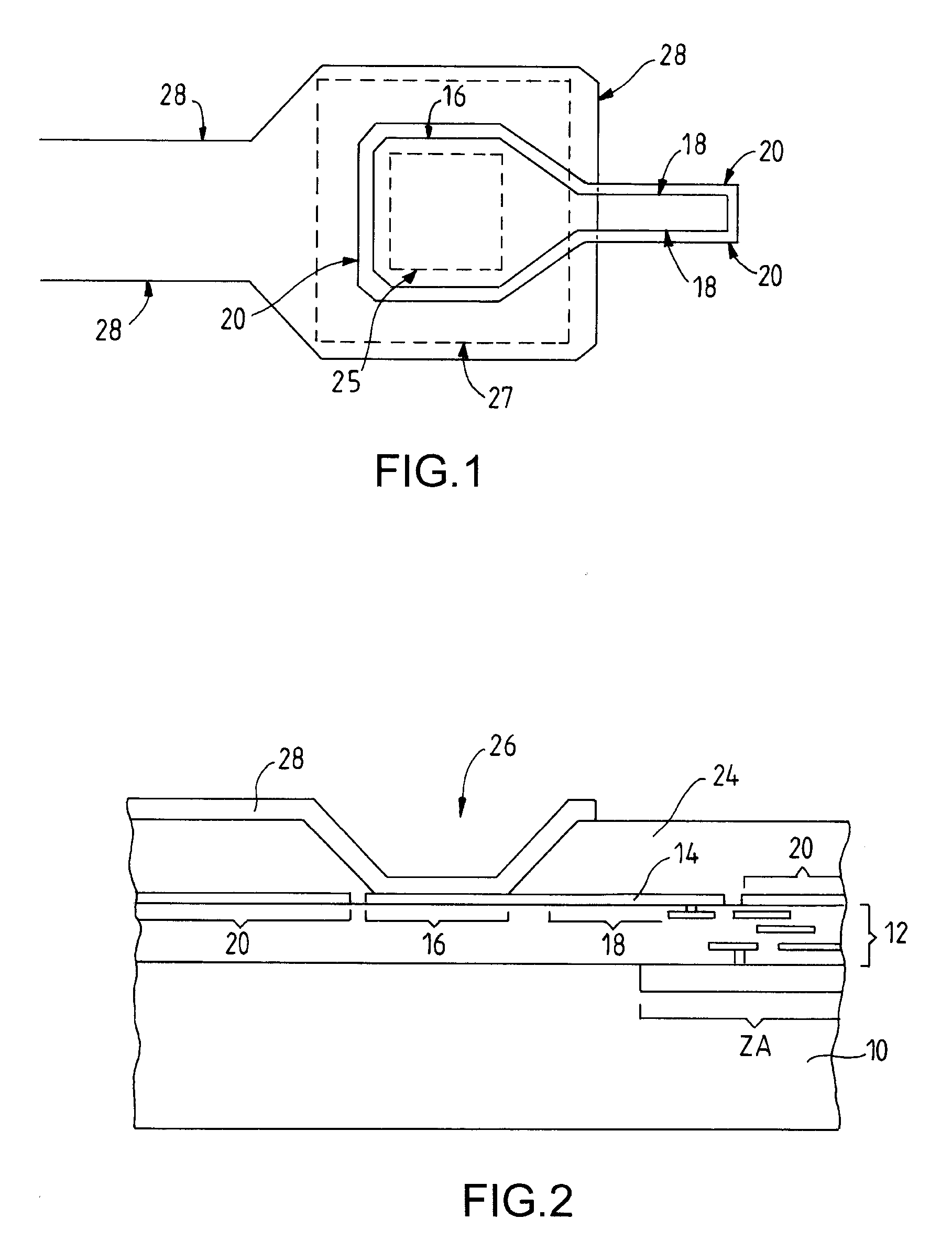

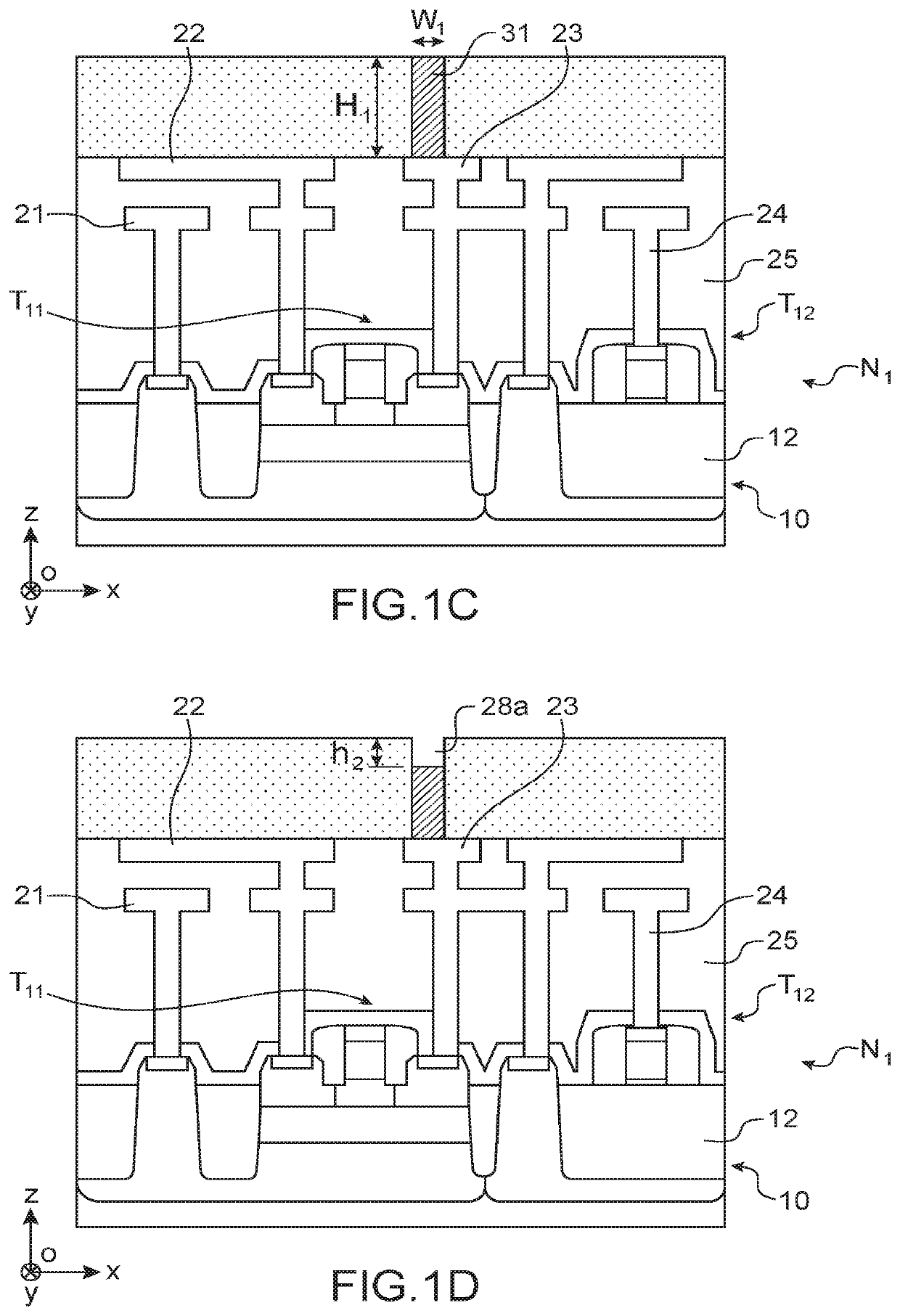

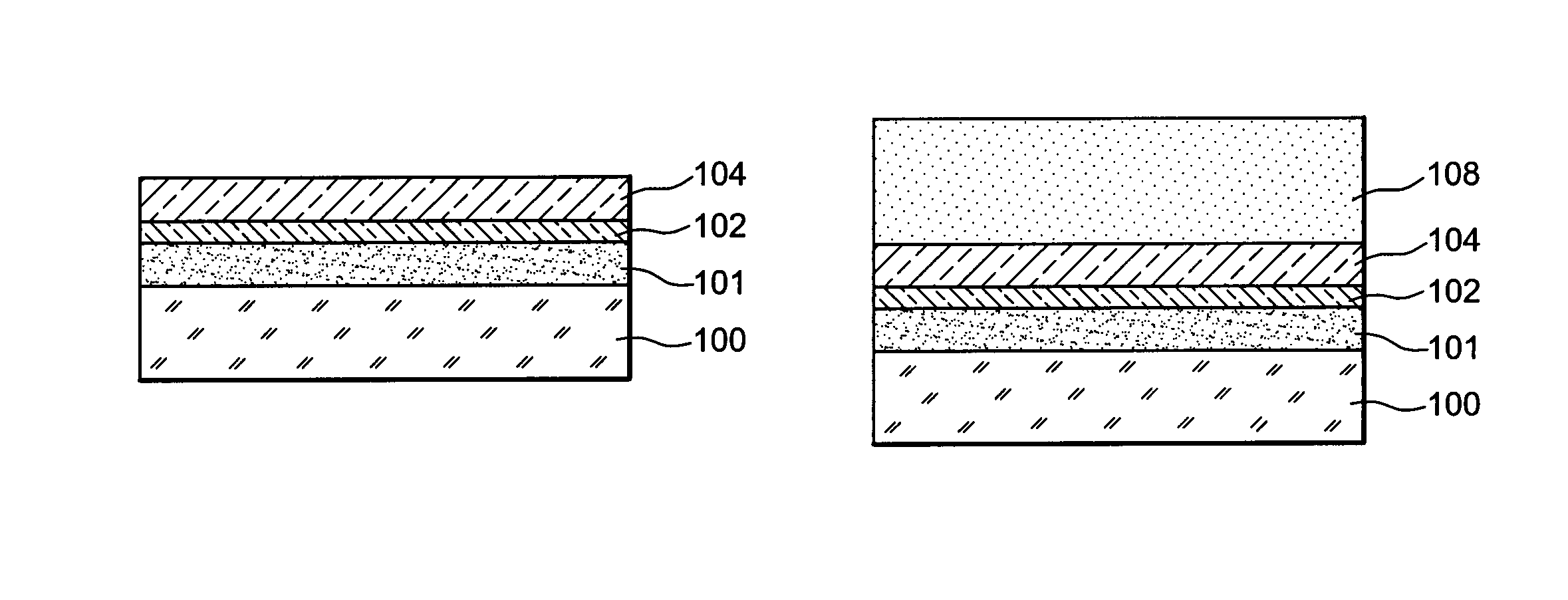

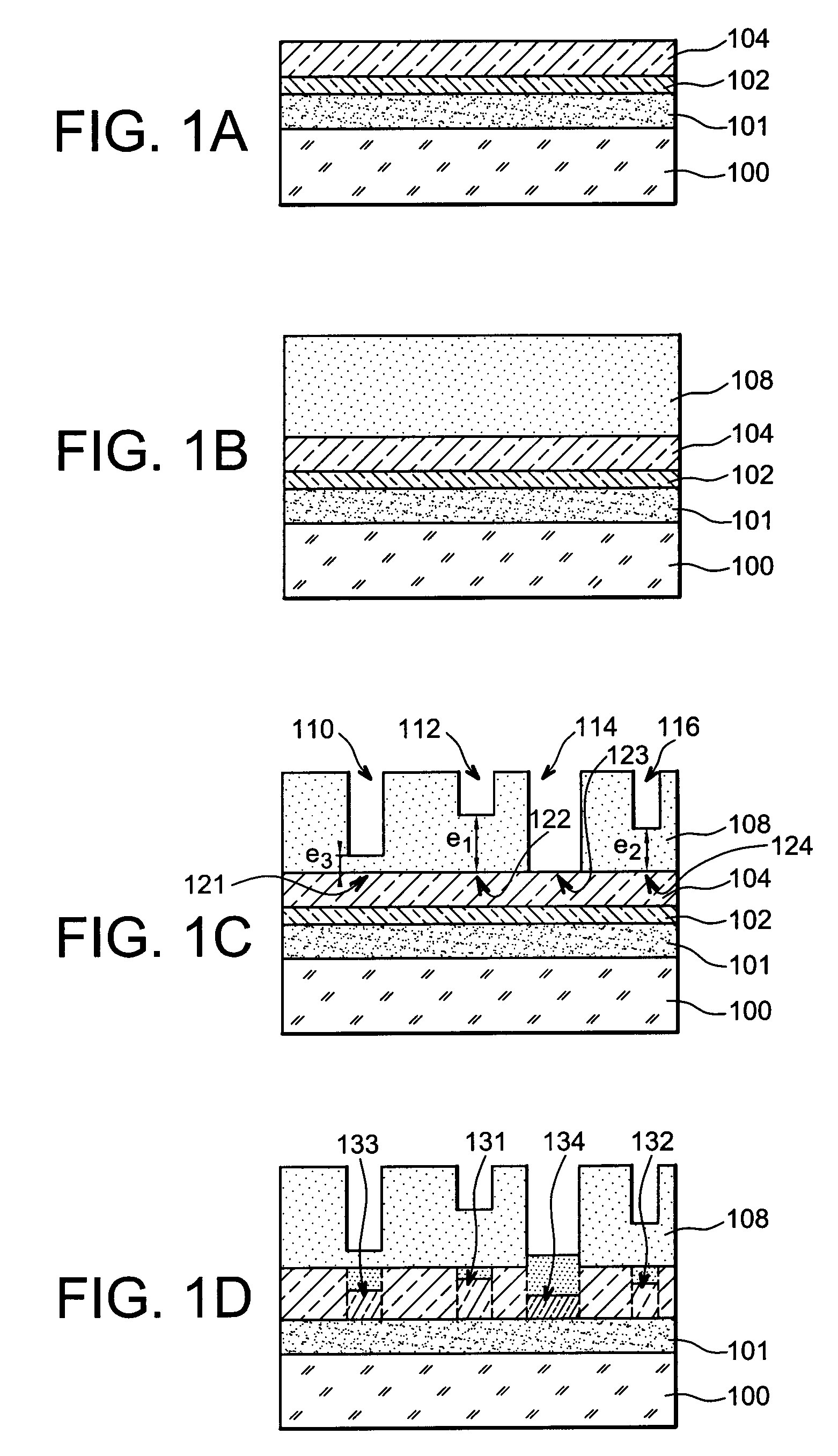

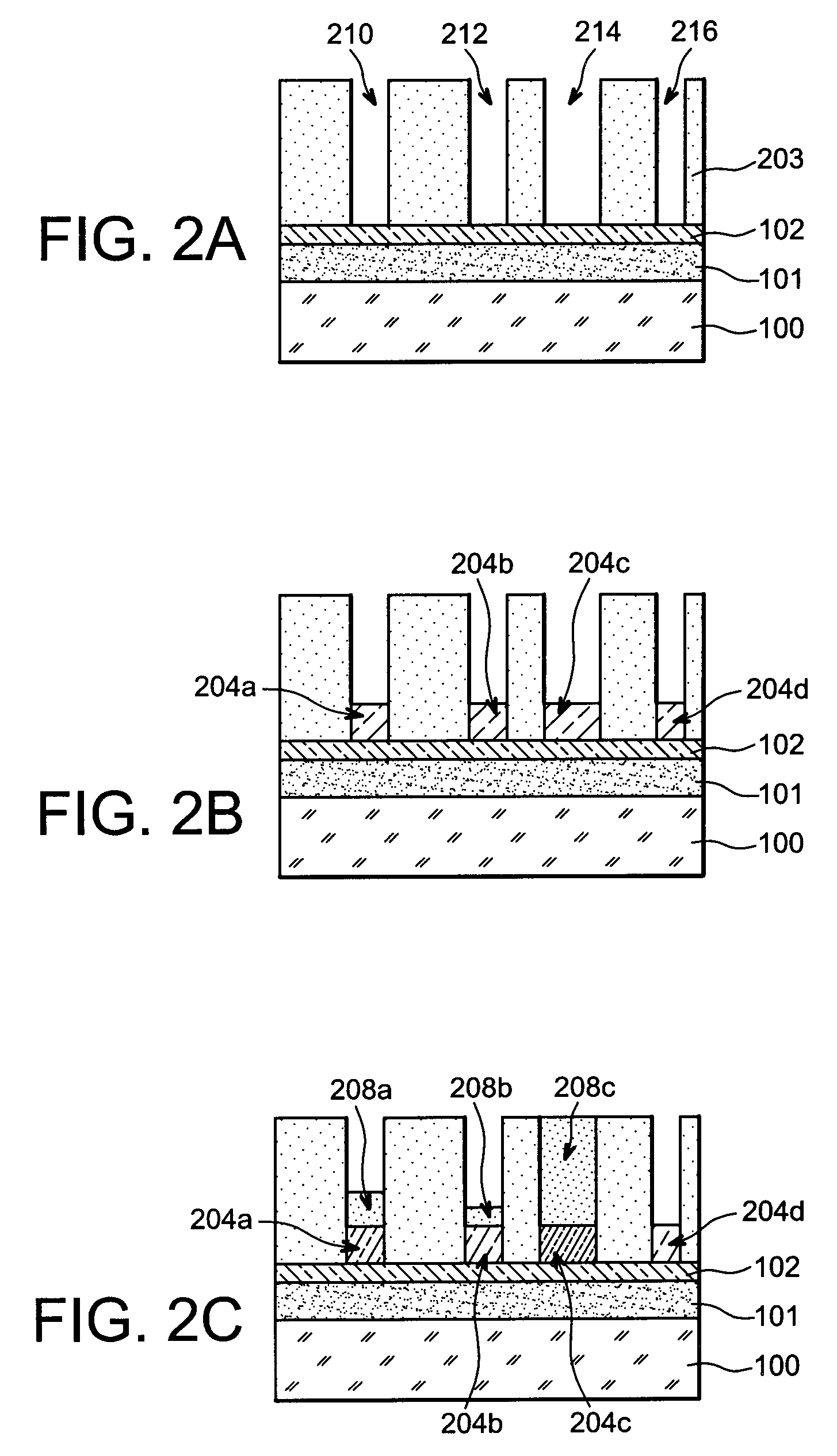

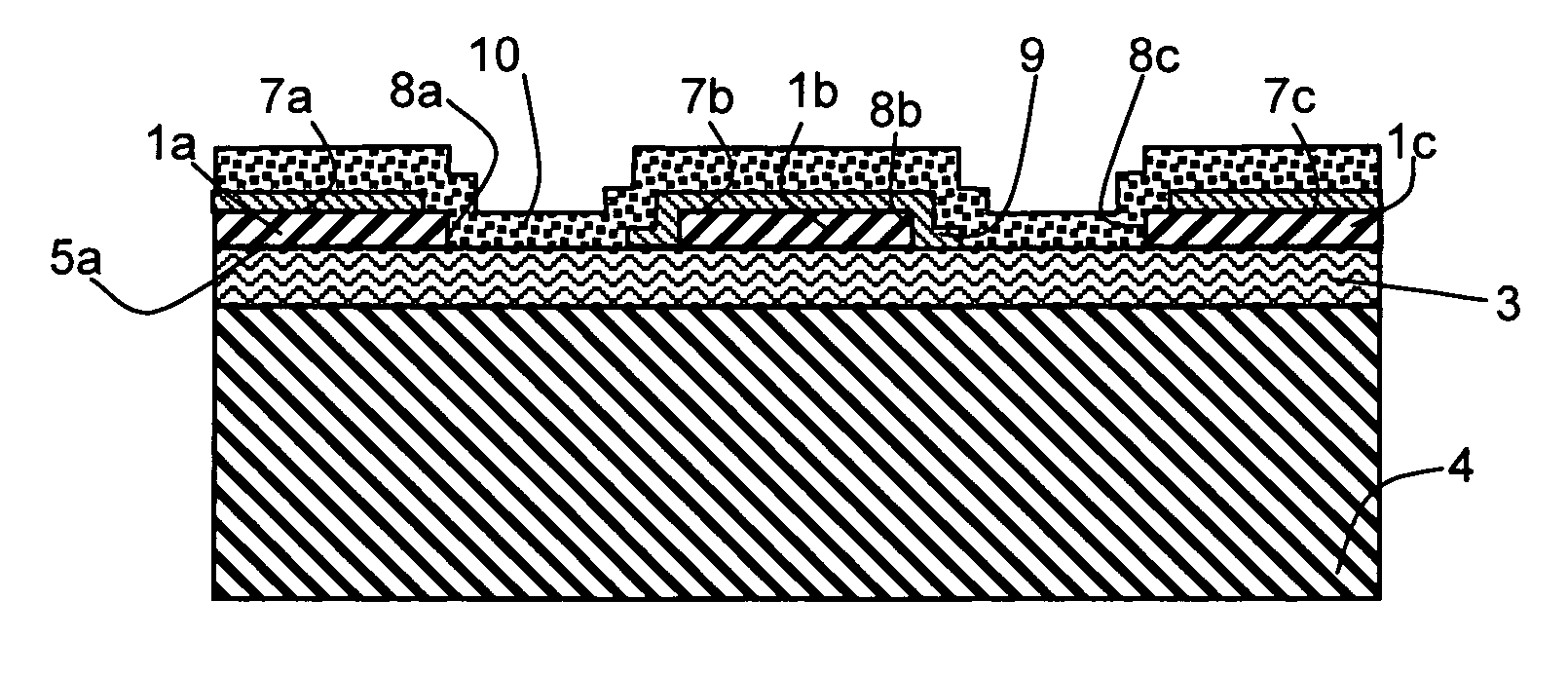

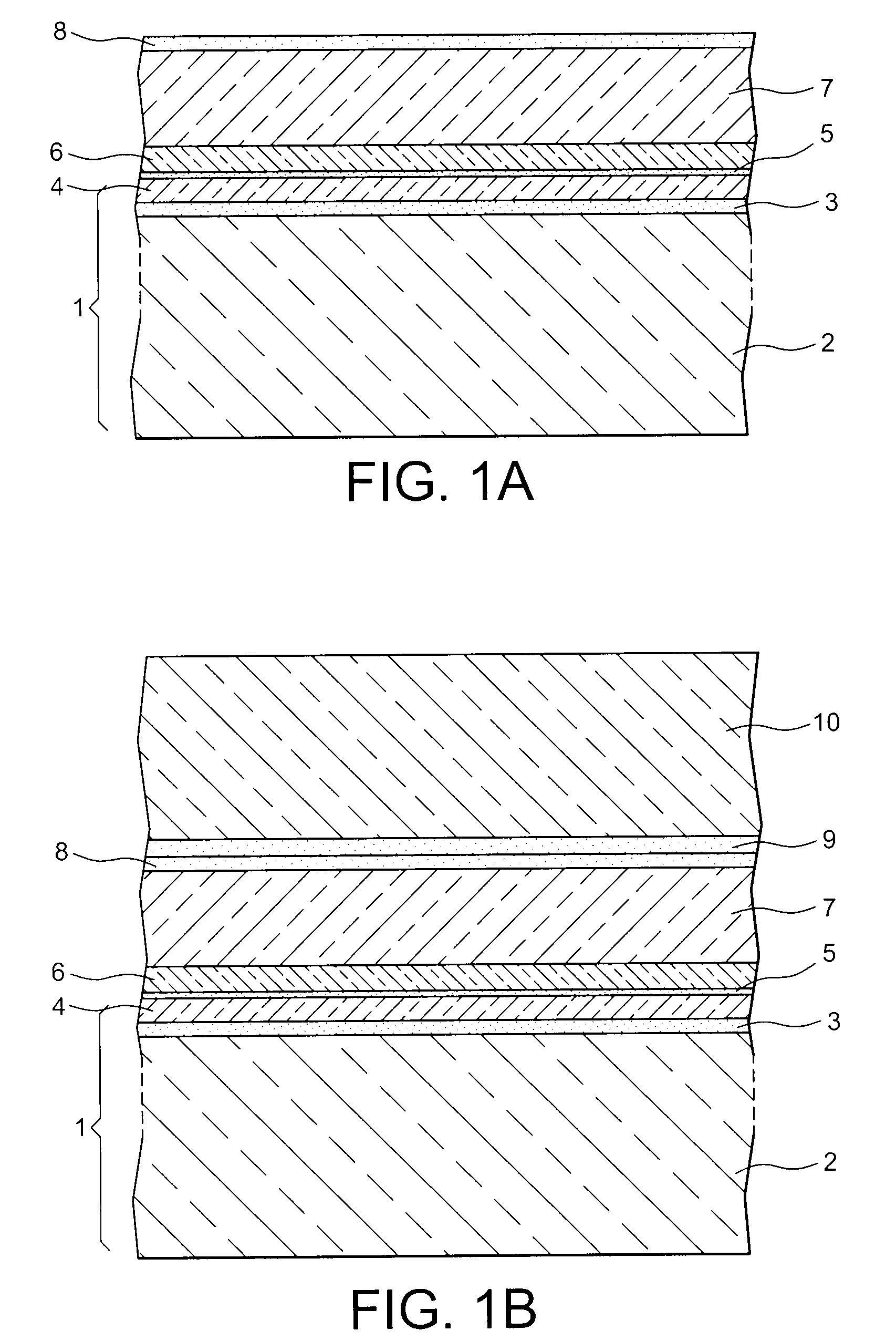

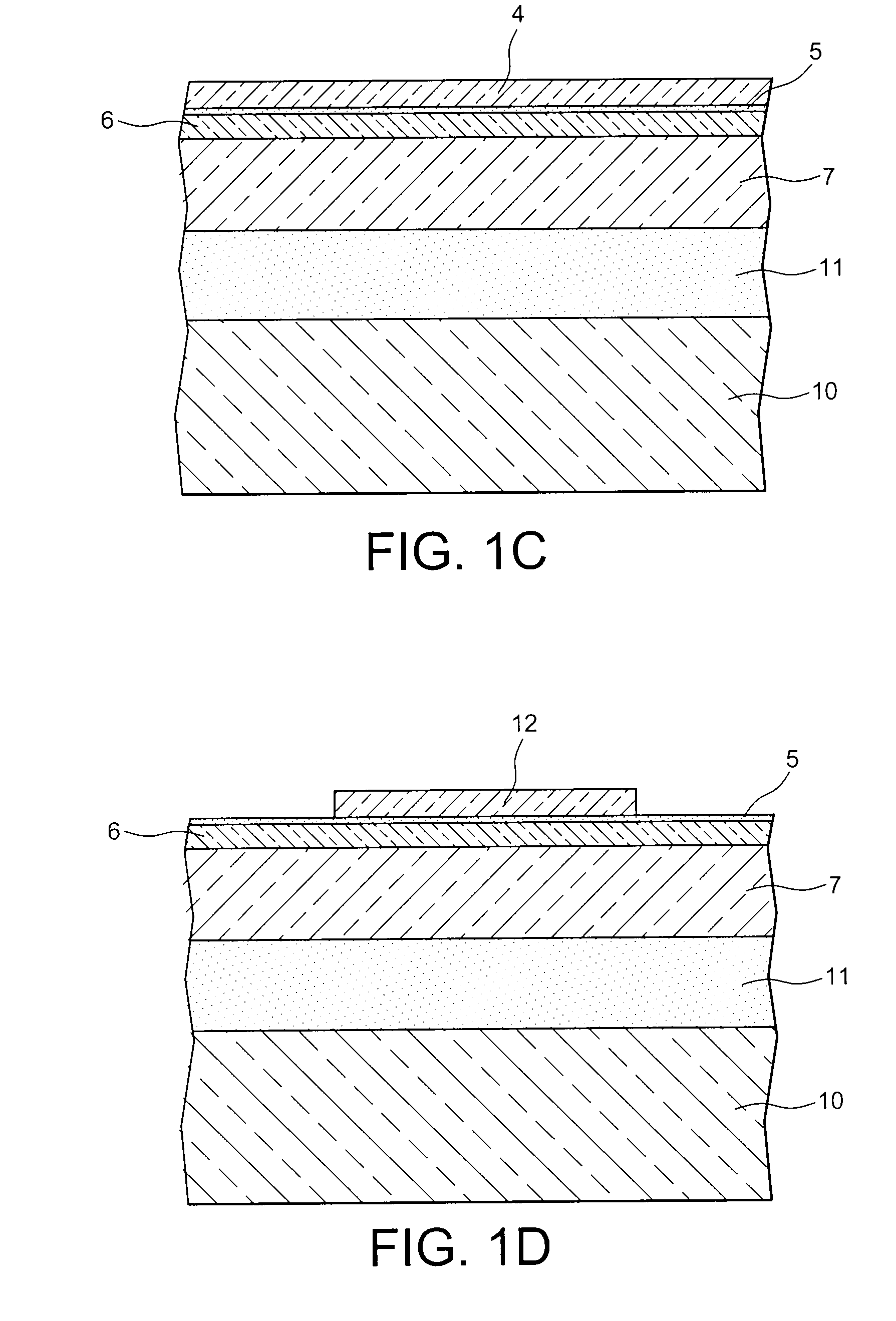

Method for producing si1-ygey based zones with different contents in ge on a same substrate by condensation of germanium

ActiveUS20070284625A1Semiconductor/solid-state device detailsSolid-state devicesComputer scienceSemiconductor

The disclosure relates to a method for producing a microelectronic device including a plurality of Si1-yGey based semi-conducting zones (where 0<y≦1) which have different respective Germanium contents, comprising the steps of:a) formation on a substrate covered with a plurality of Si1-yGey based semi-conducting zones (where 0<x<1 and x<y) and identical compositions, of at least one mask comprising a set of masking blocks, wherein the masking blocks respectively cover at least one semi-conducting zone of the said plurality of semi-conducting zones, wherein several of said masking blocks have different thicknesses and / or are based on different materials,b) oxidation of the semi-conducting zones of the said plurality of semi-conducting zones through said mask.

Owner:COMMISSARIAT A LENERGIE ATOMIQUE ET AUX ENERGIES ALTERNATIVES +1

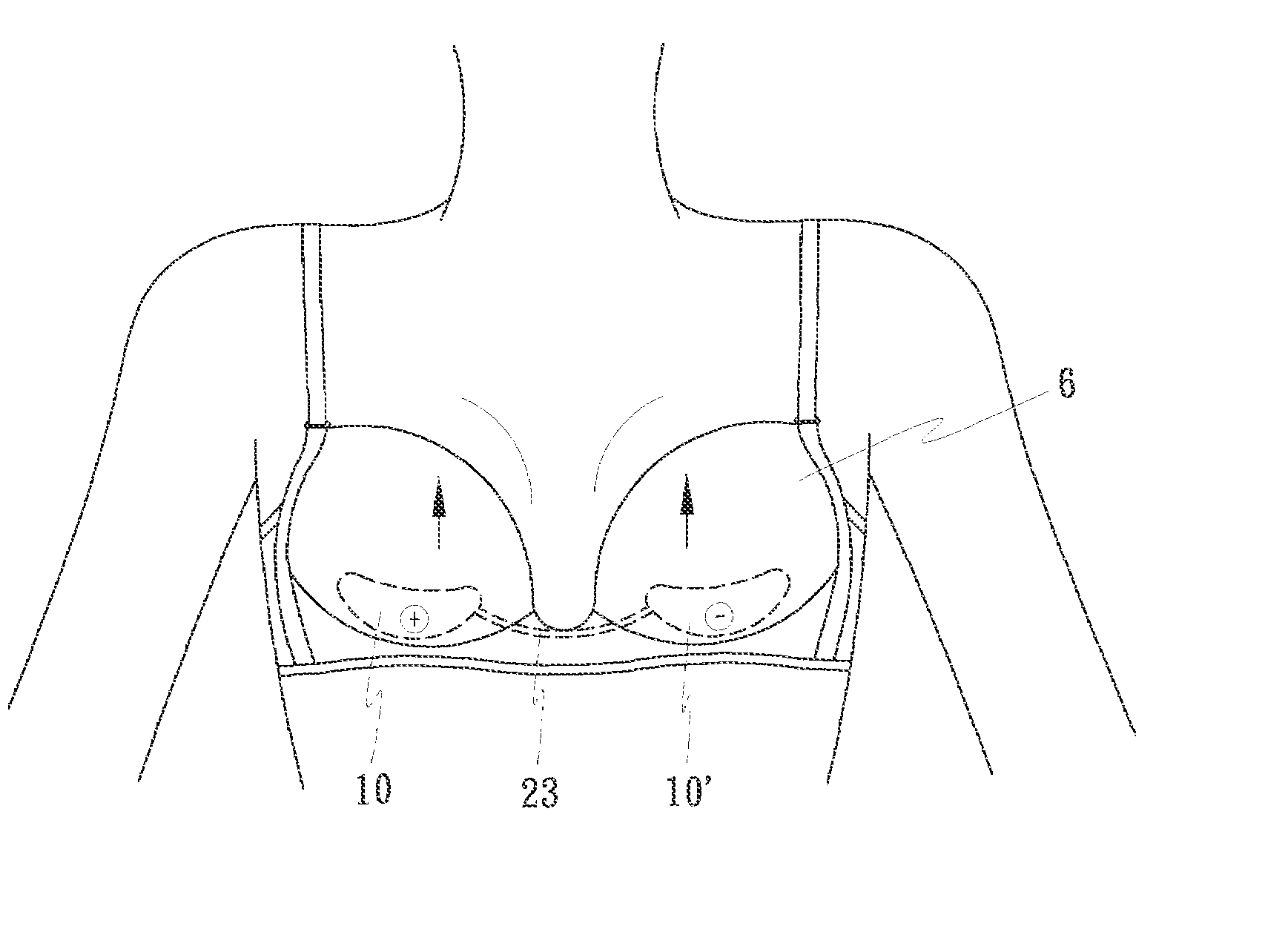

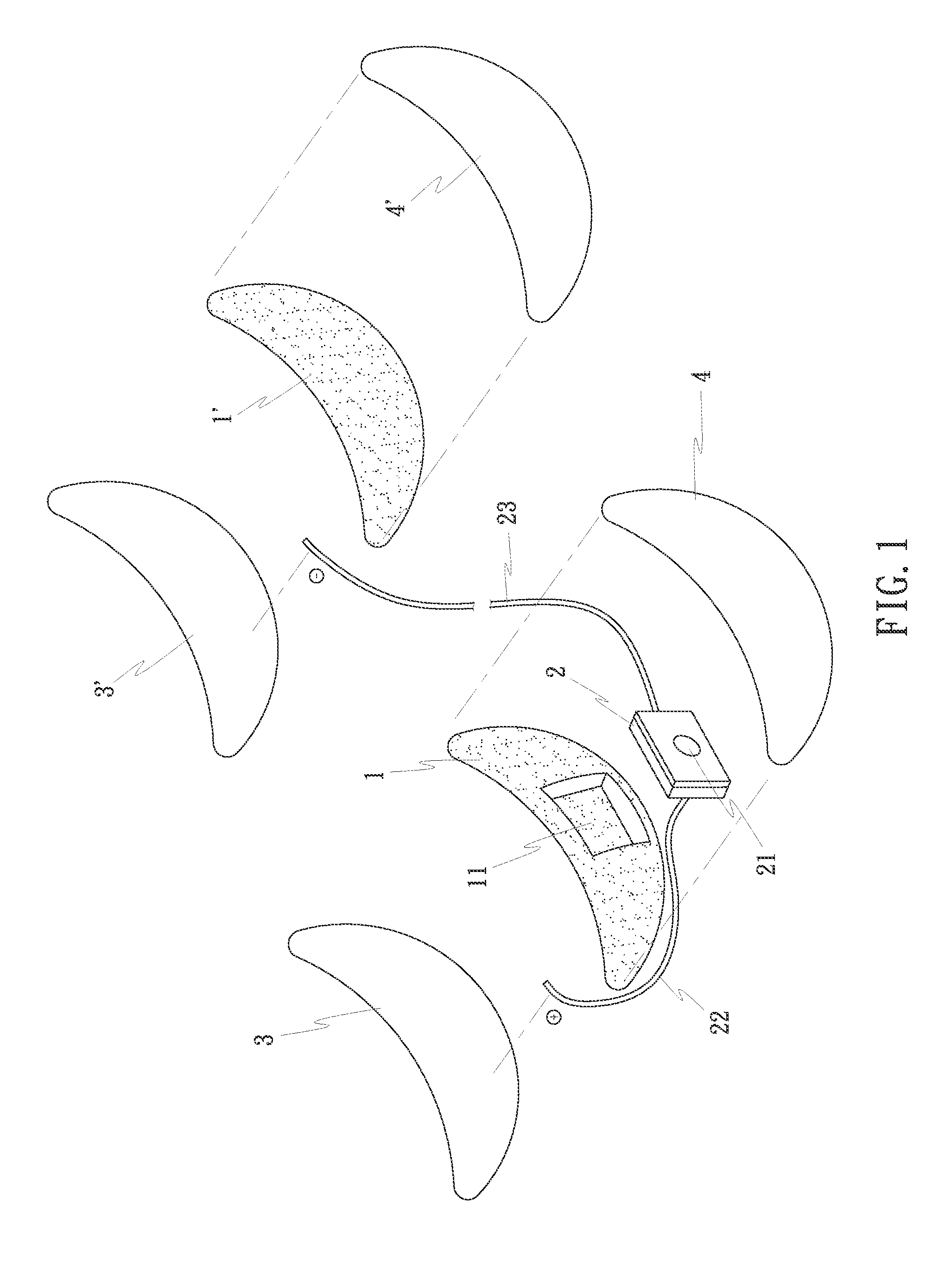

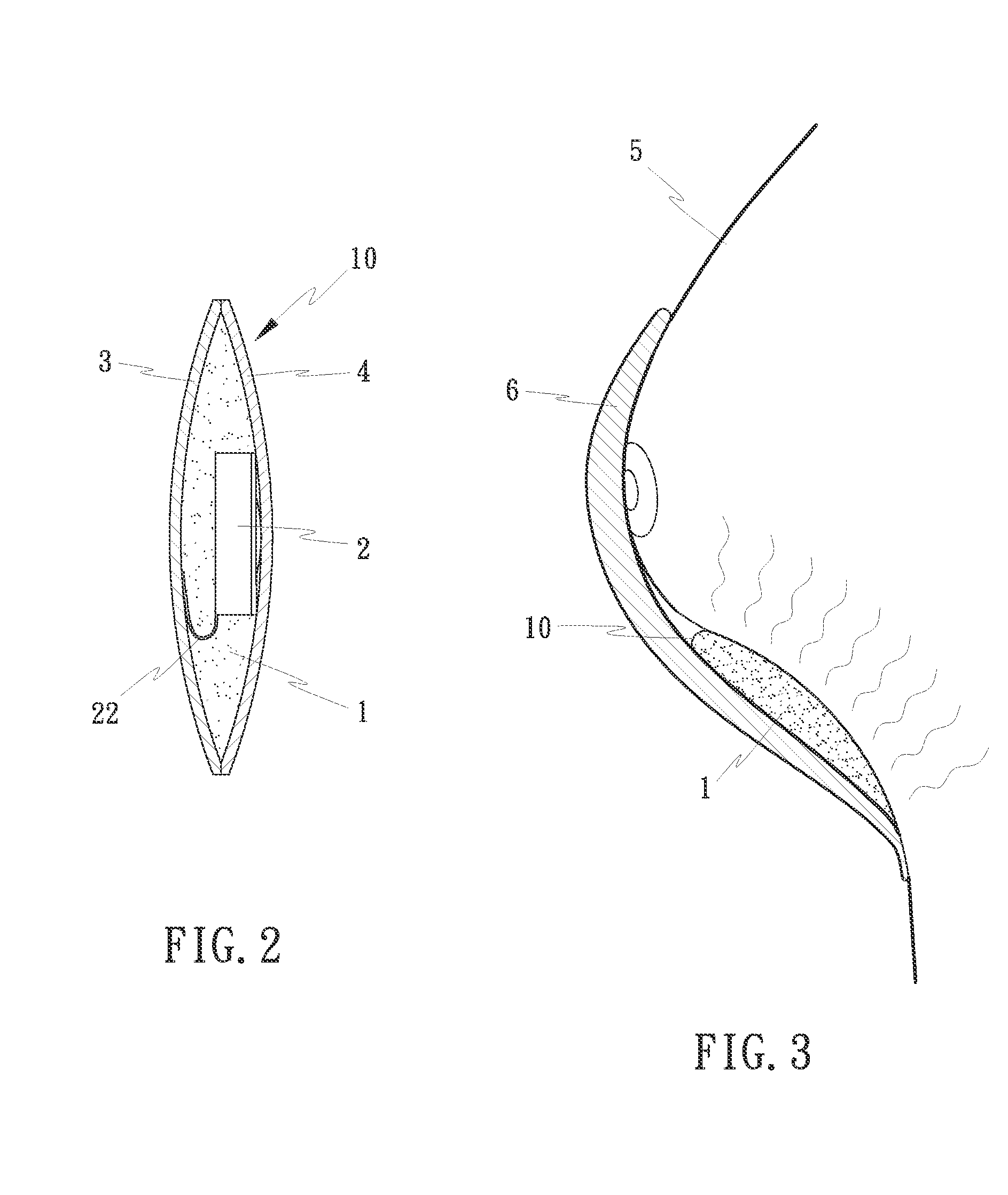

Micro-current massaging brassiere pad

A micro-current massaging brassiere pad includes a flexible pad, a controller mounted in the pad and having a control IC for outputting a pulse waveform and two lead wires for connection to the positive pole and the negative pole of a power source respectively, an electrically insulative outer cover layer covered on the outer side of the pad, and an inner cover layer covered on the inner side of the pad for direct contact with one breast of a female user, the inner cover layer having two isolated conducting zones respectively connected to the two lead wires of the controller such that when electricity is connected through the lead wires of the controller, a medium or low frequency pulse is discharged through the inner cover layer to stimulate the breast of the female user.

Owner:SHAO HUNG CHIANG

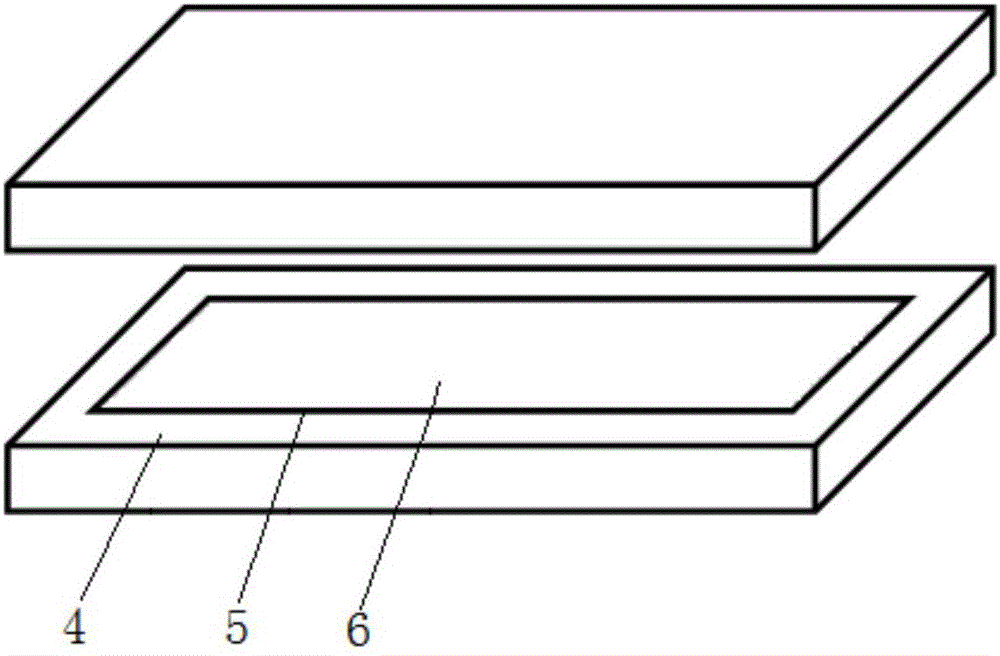

Scanning method for material increase manufacturing three-dimensional body

ActiveCN105710366AGuaranteed machining accuracyImprove scanning processing efficiencyAdditive manufacturing apparatusCeramic shaping apparatusSurface layerAdditive layer manufacturing

The invention discloses a scanning method for a material increase manufacturing three-dimensional body. The scanning method includes the steps that a certain value is set to serve as a three-dimensional body surface layer zone threshold value; then the whole three-dimensional body is divided into a surface layer zone and an internal zone according to the threshold value; small light spot heat source scanning is adopted on the surface layer zone, and large light spot heat source scanning is adopted on the internal zone; and scanning is completed. By means of the scanning method, a user can freely set the surface layer zone thickness threshold value according to the machining requirement, a single-deck section to-be-scanned zone of the three-dimensional body is divided into the surface layer zone and the internal zone, different scanning parameters are further adopted to conduct zone dividing scanning on the surface layer zone and the internal zone, the machining accuracy of the three-dimensional body is guaranteed, and the scanning machining efficiency of the three-dimensional body is improved. The user can further take a scanning strategy that scanning machining of the internal zone is carried out one time after the multi-layer surface layer zone is scanned according to the machining requirement, and the machining accuracy and the machining efficiency are balanced to the maximum degree.

Owner:XIAN BRIGHT ADDTIVE TECH CO LTD

Water supply pipe network pipe burst and leakage preliminary positioning method

ActiveCN109869638AQuick fixReduce lost fix timeCharacter and pattern recognitionPipeline systemsEngineeringAbnormal pressure

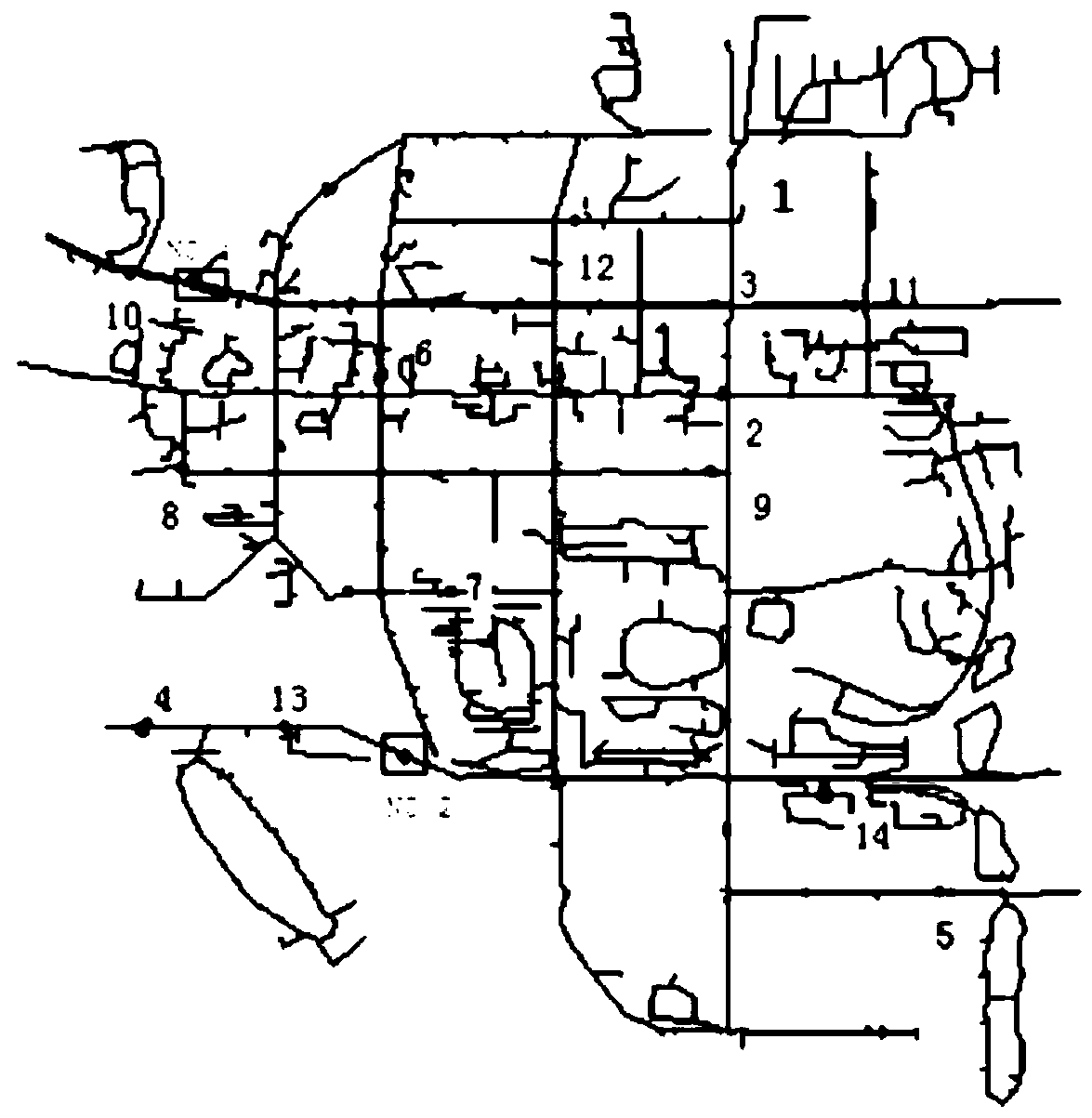

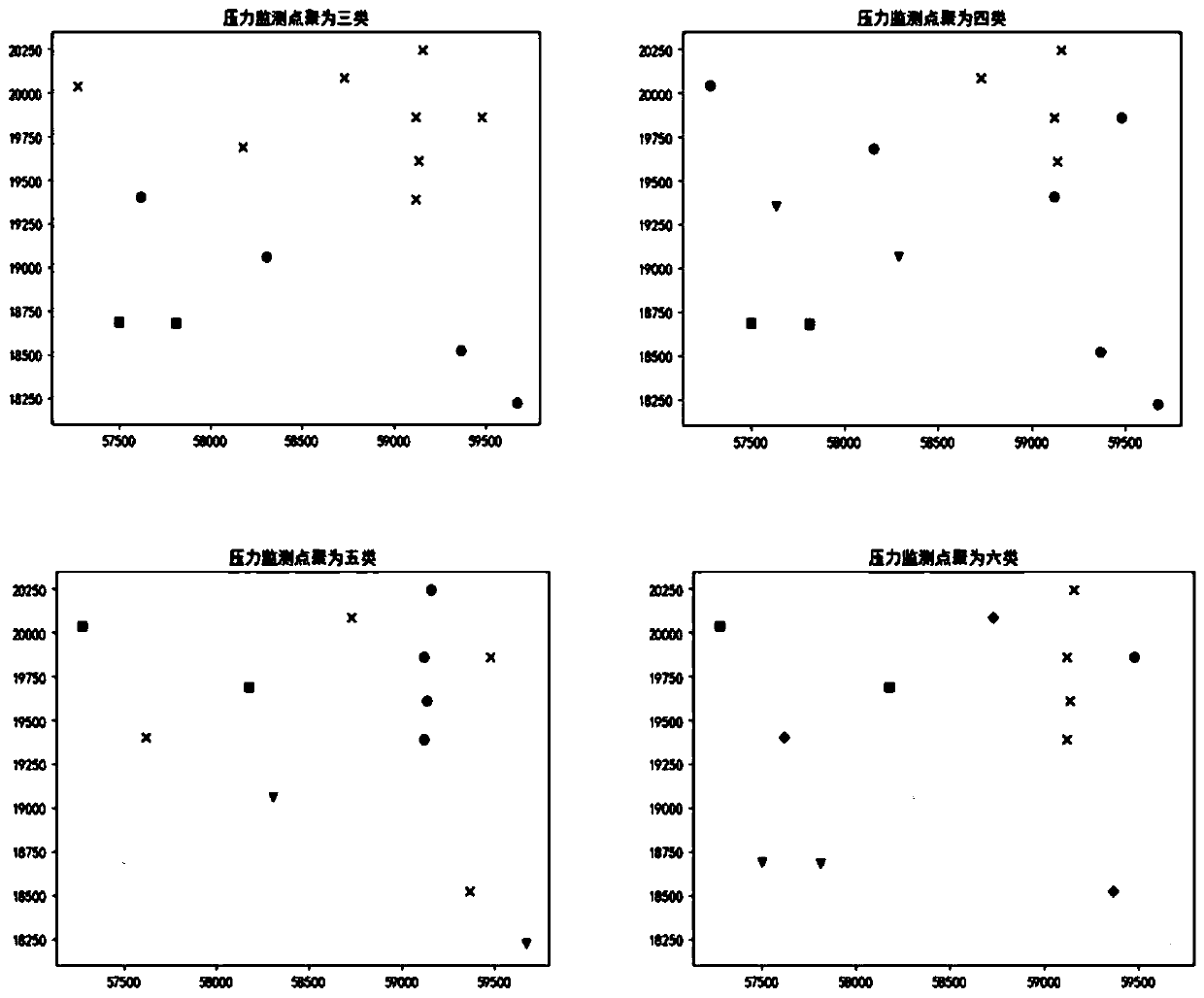

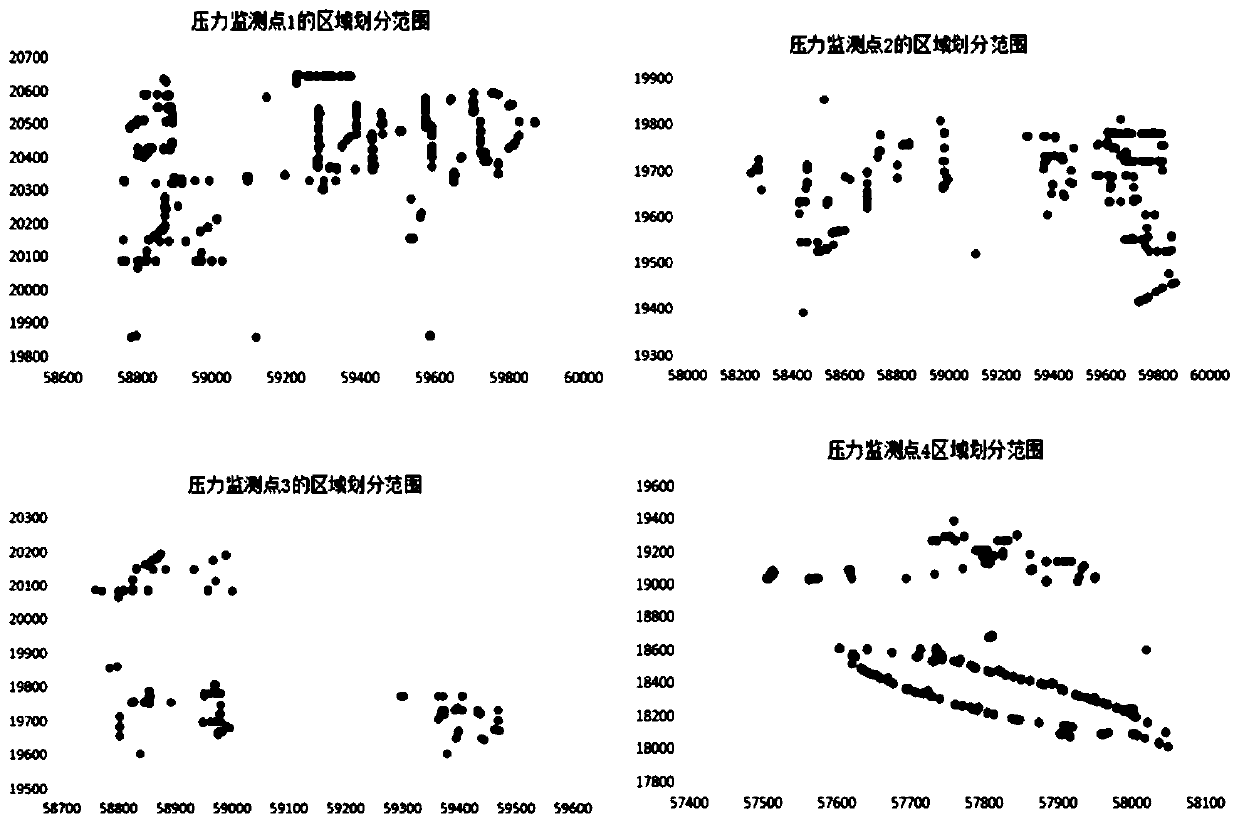

The invention discloses a water supply pipe network pipe burst and leakage preliminary positioning method. The preliminary positioning method comprises the steps of conducting zoning on a water supplypipe network based on spectral clusters; judging whether abnormal change occurs to the pressure of a pressure monitoring point or not through a CUSUM algorithm; and finally, positioning the water supply pipe network zone at the spectral cluster where the abnormal pressure monitoring point is located according to the abnormal pressure monitoring point and preliminarily judging a pipe burst and leakage incident occurs in the zone where the pressure monitoring point is located. Through the method, the related zones of the pressure monitoring points do not need to be repeatedly partitioned, the leakage positioning time can be shortened, and quick and flexible leakage preliminary positioning can be realized.

Owner:HANGZHOU DIANZI UNIV

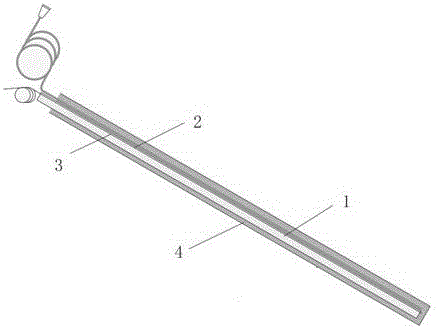

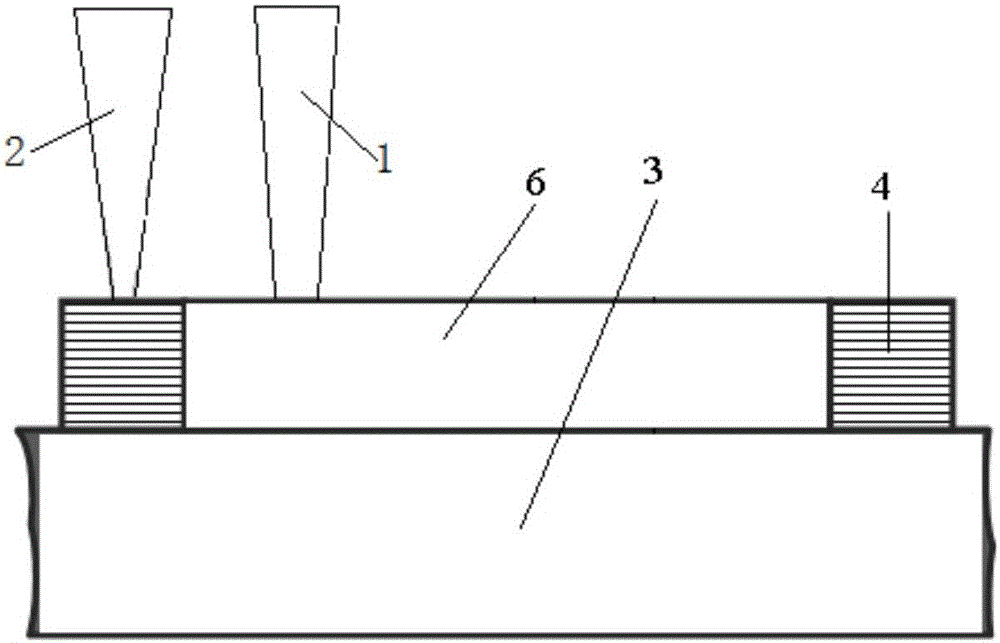

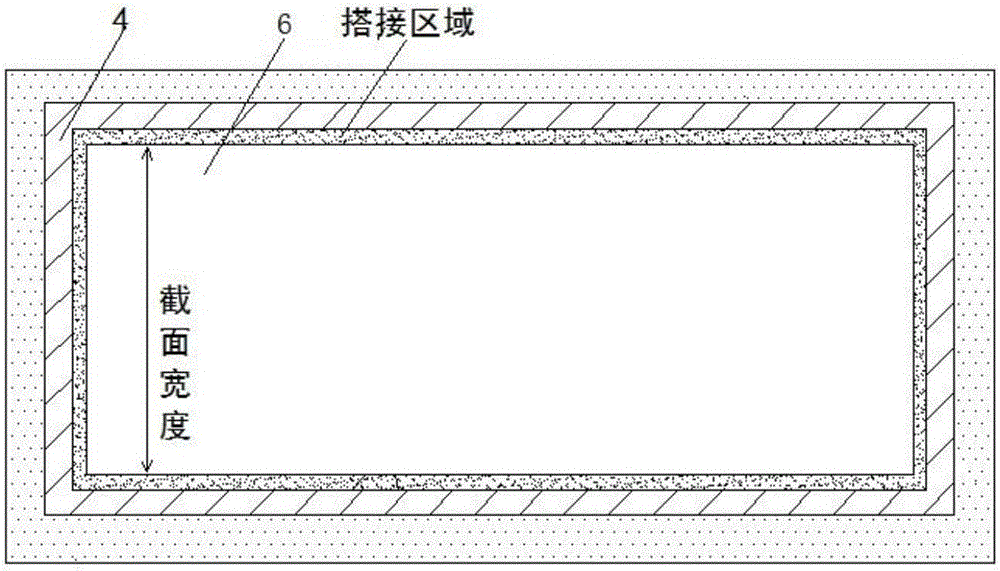

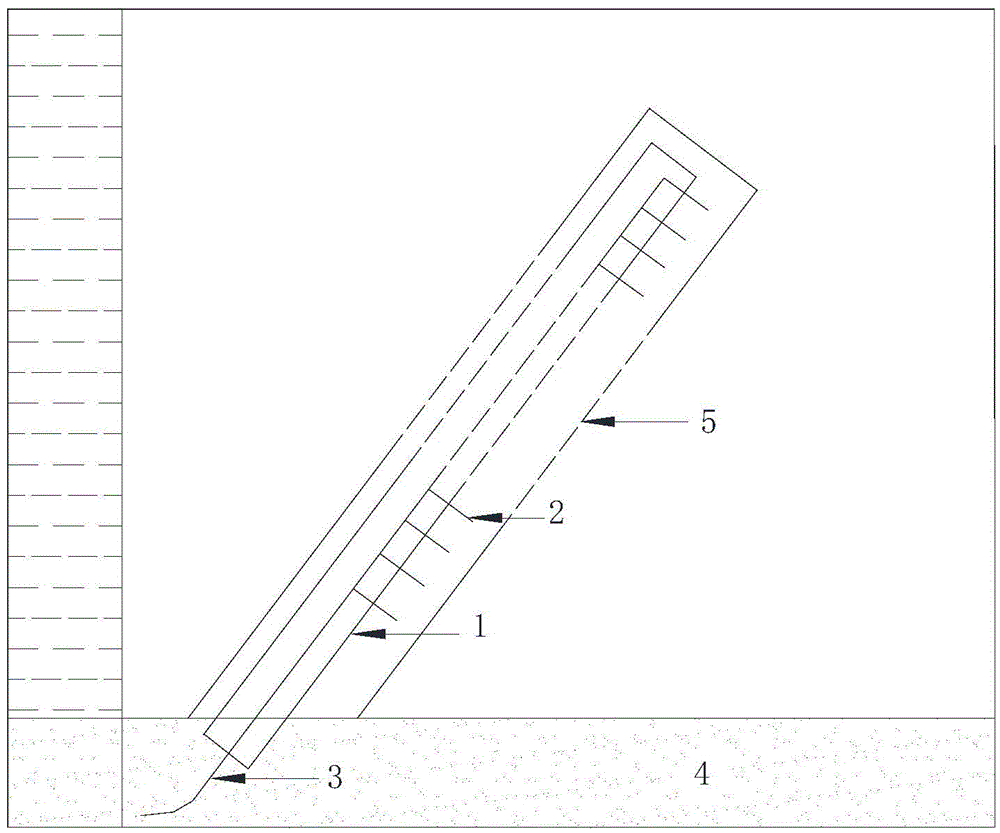

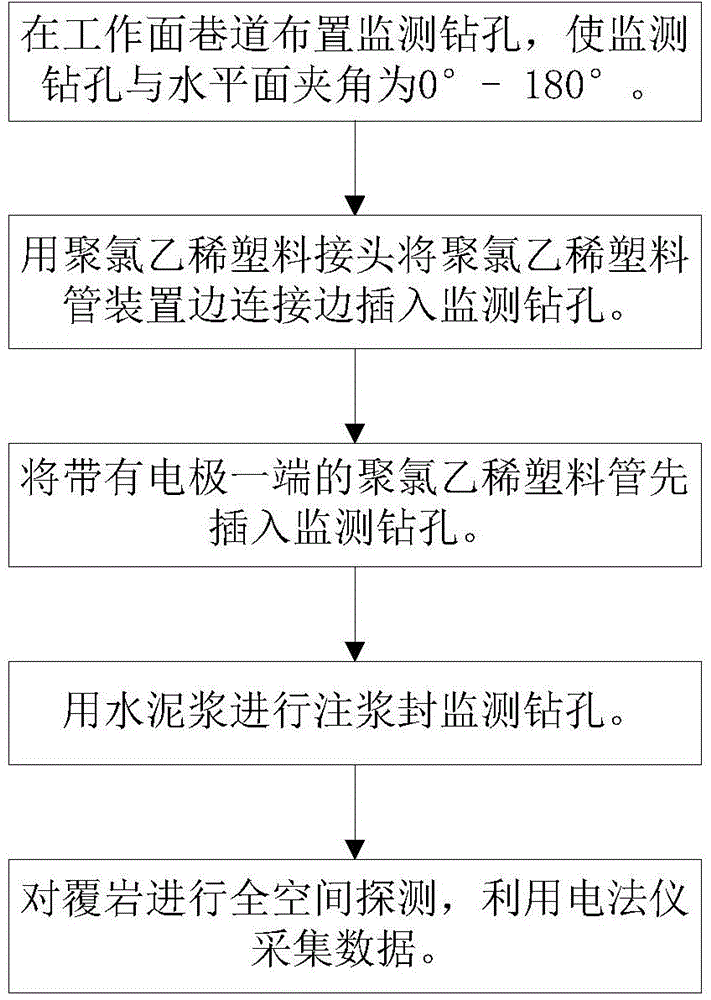

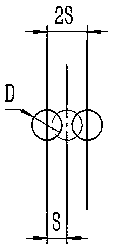

Drilling electrical prospecting device and method for overburden water-conducting zone

InactiveCN104405376AEasy to makeEasy loading and unloadingBorehole/well accessoriesPolyvinyl chlorideRebar

The invention relates to a drilling electrical prospecting device and method for an overburden water-conducting zone, and belongs to the technical field of prospecting. The drilling electrical prospecting device comprises a plurality of polyvinyl chloride plastic pipes and steel bars serving as electrodes, wherein a fixing hole is drilled in the middle of each polyvinyl chloride plastic pipe; the intervals between adjacent fixing holes are 2 meters; the steel bars are inserted into the fixing holes for fixing; electric wires arranged in the steel bars are taken as electrode cables; the electric wires pass through the polyvinyl chloride plastic pipes. The drilling electrical prospecting device and method for the overburden water-conducting zone disclosed by the invention have the advantages of total-space prospecting of the overburden water-conducting zone, wider prospecting range, higher prospecting accuracy and higher working efficiency. Necessary basic geological data is provided for hazard control, and a novel geophysical prospecting measure is provided for the prevention and control of coal mine flooding.

Owner:SHANDONG UNIV OF SCI & TECH

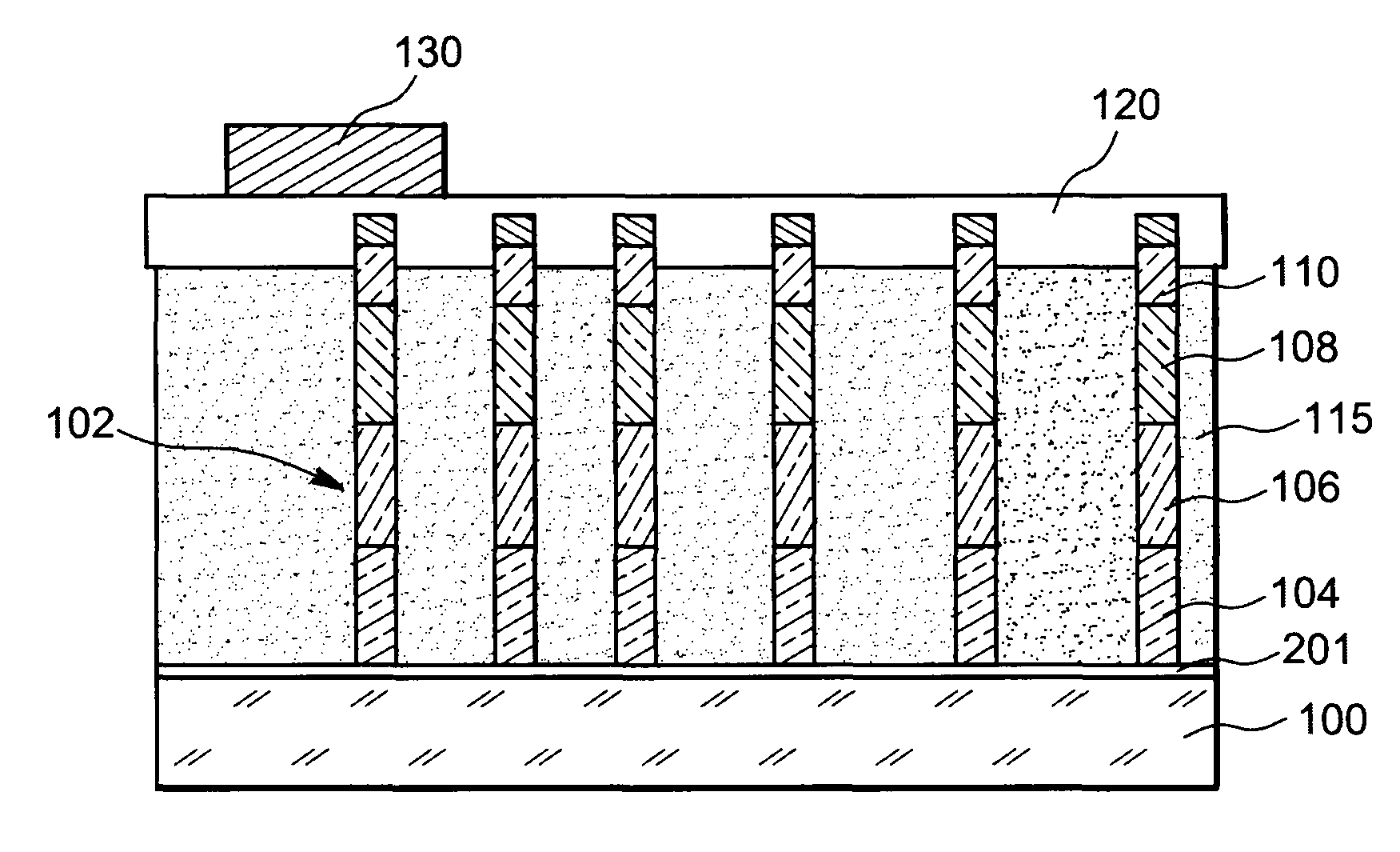

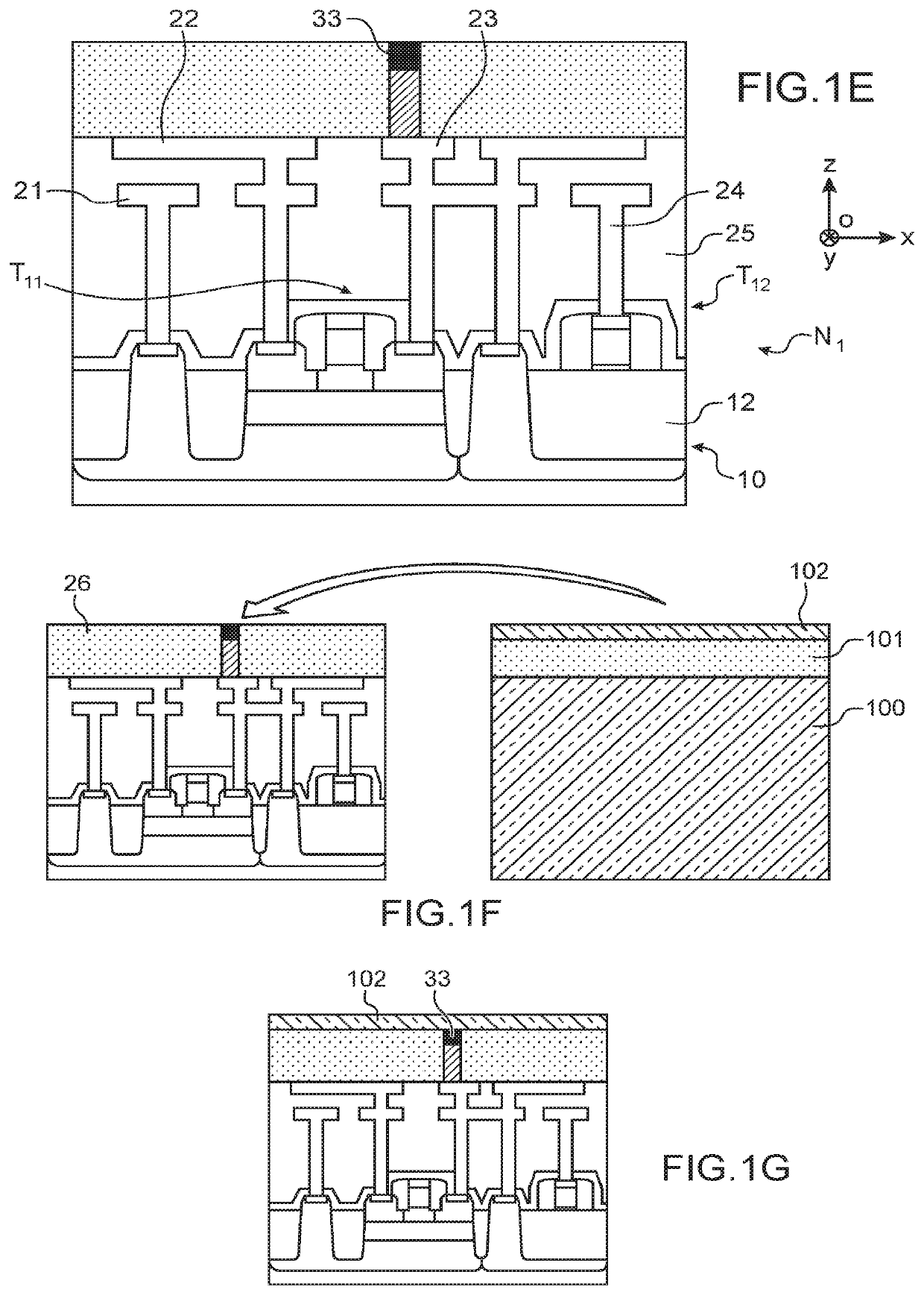

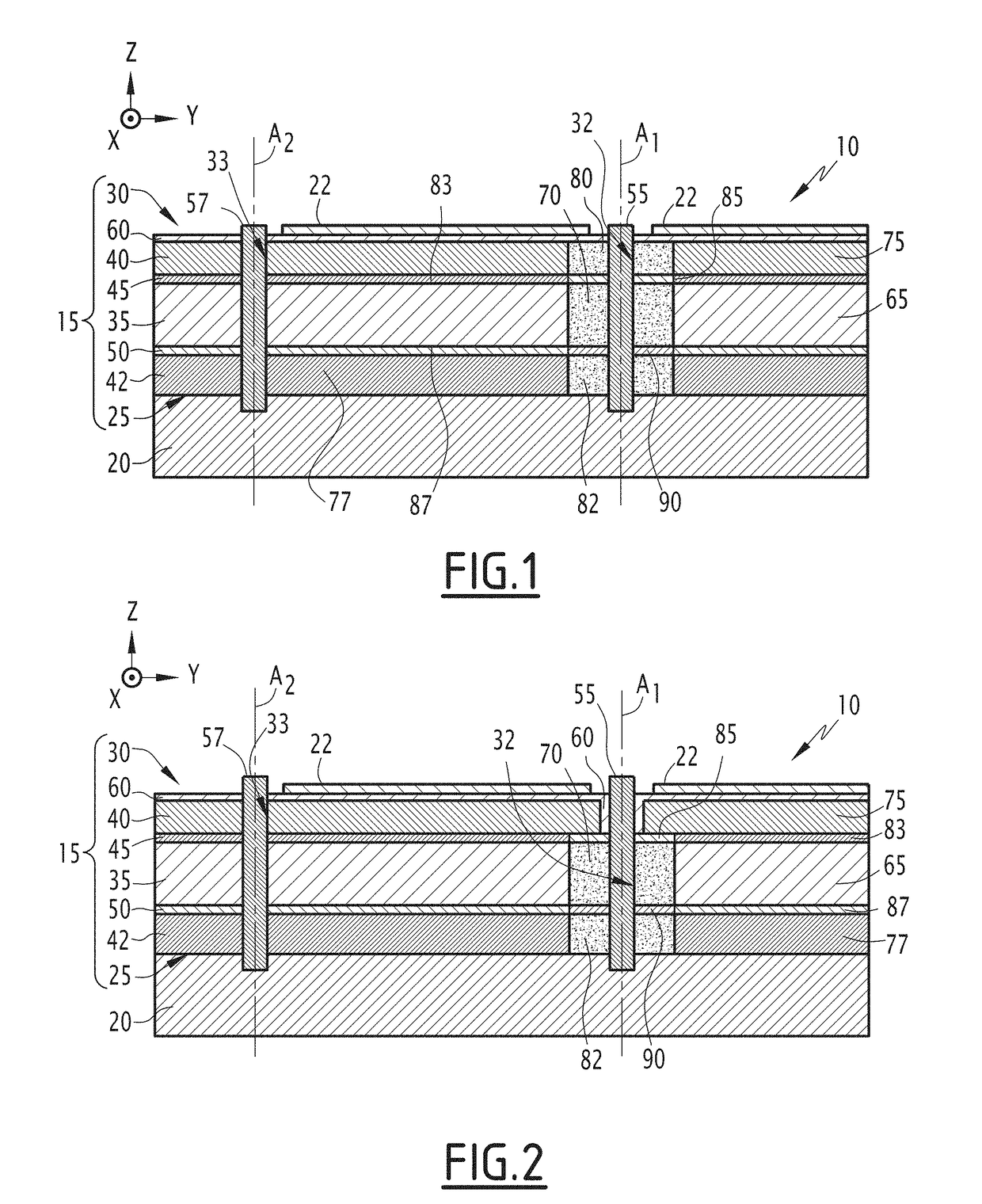

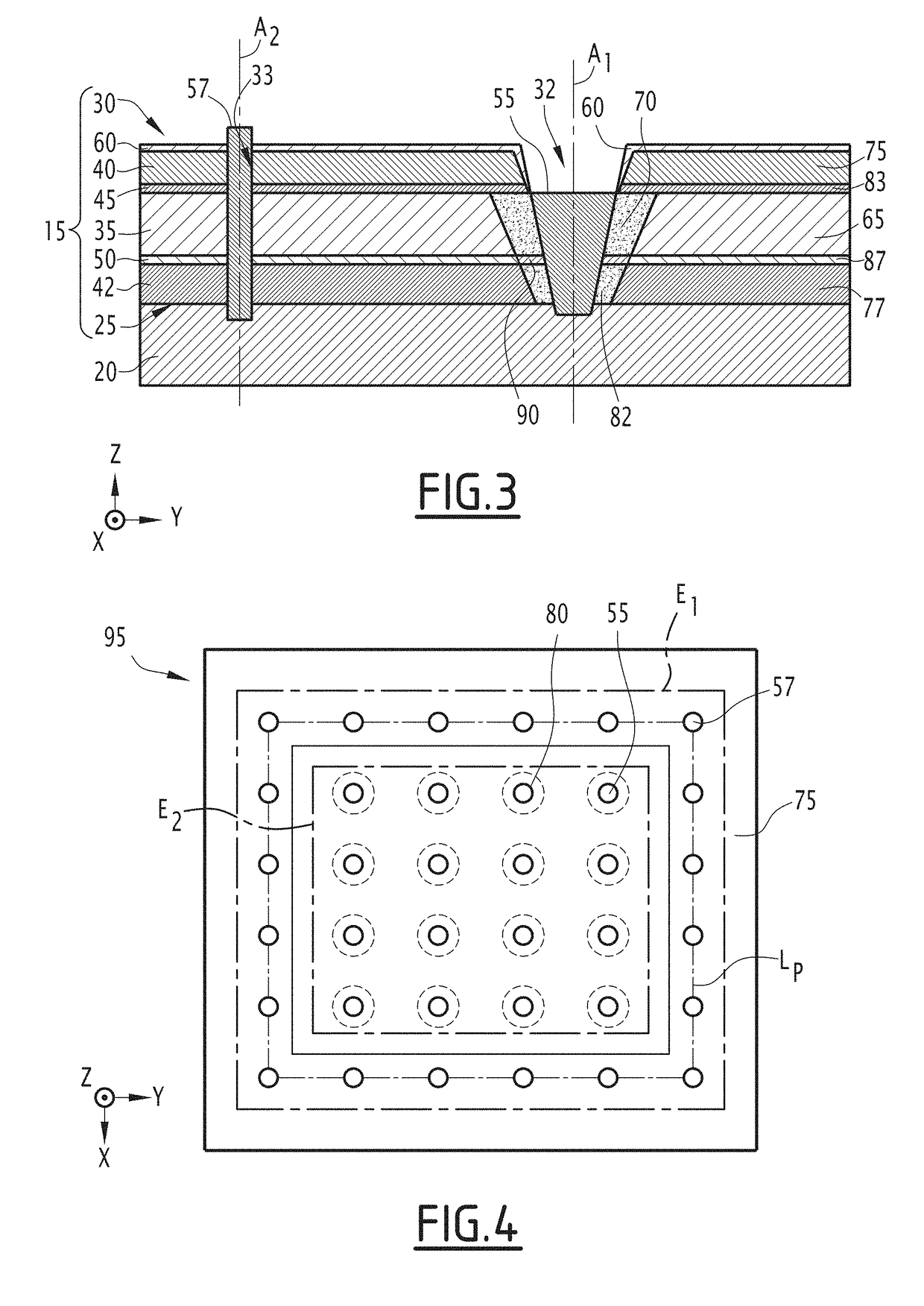

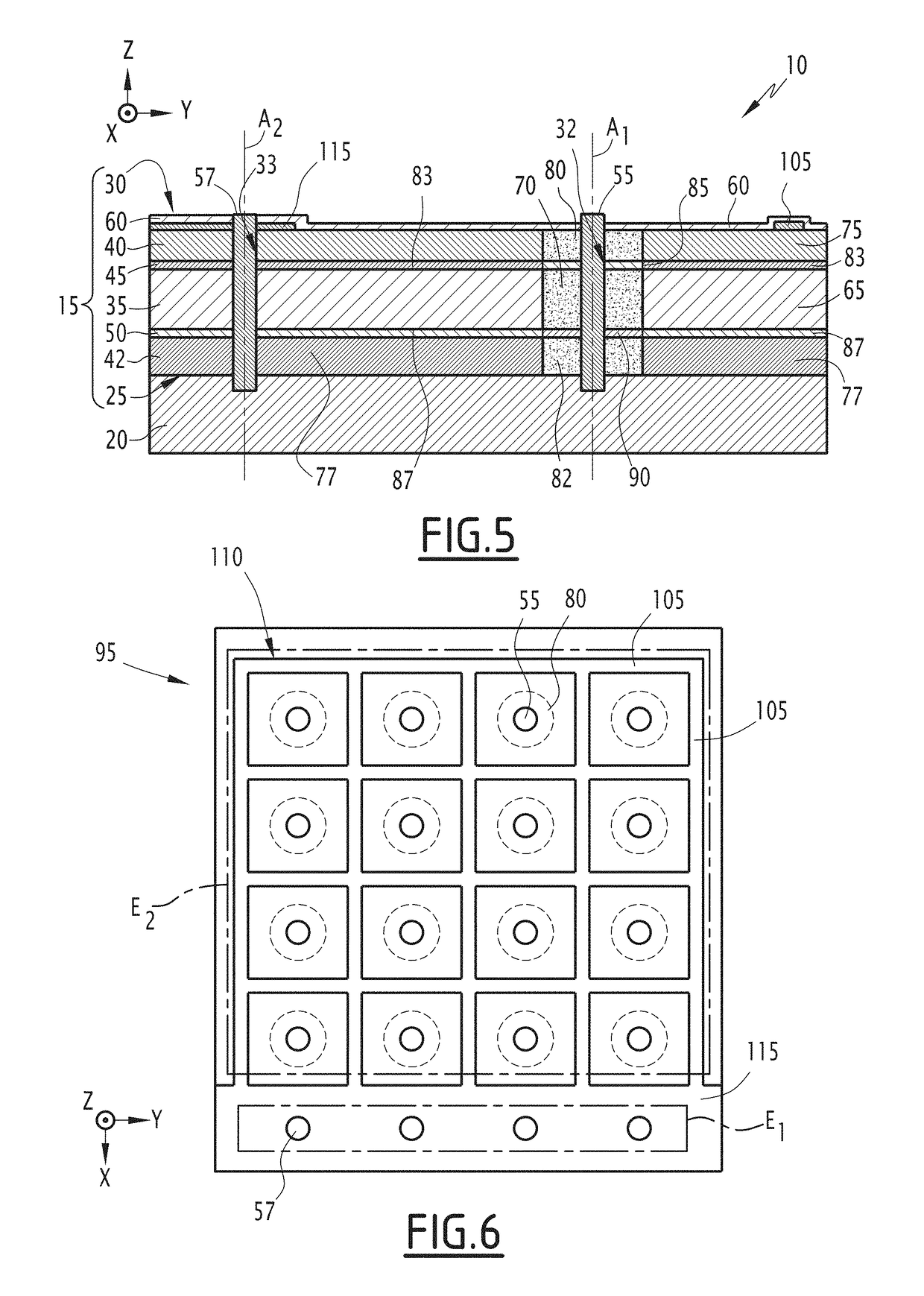

Method for providing mixed stacked structures, with various insulating zones and/or electrically conducting zones vertically localized

Owner:COMMISSARIAT A LENERGIE ATOMIQUE ET AUX ENERGIES ALTERNATIVES

Method for making a light-emitting microelectronic device with semi-conducting nanowires formed on a metal substrate

A process of making a microelectronic light-emitting device, including: a) growth on a metallic support of multiple wires based on one or more semi-conducting materials designed to emit radiant light, and b) formation of at least one electrical conducting zone of contact on at least one of the wires.

Owner:CENT NAT DE LA RECHERCHE SCI

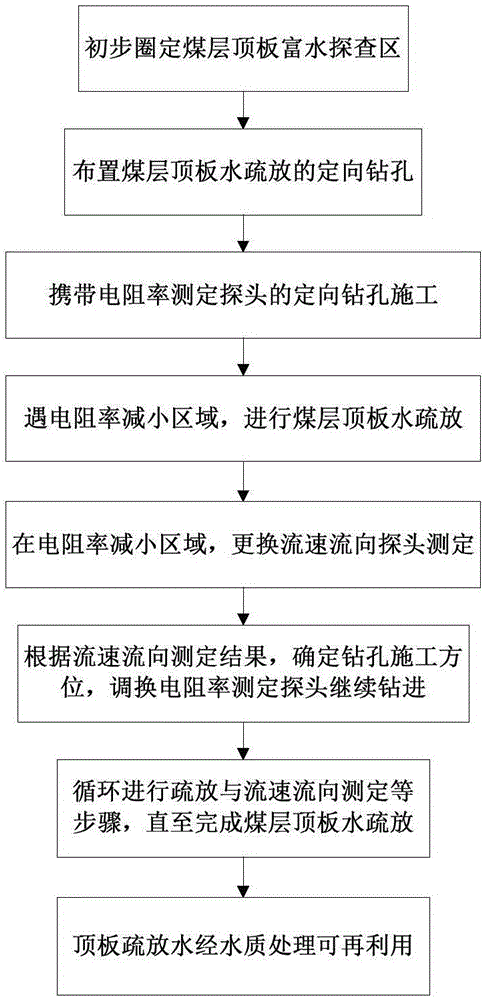

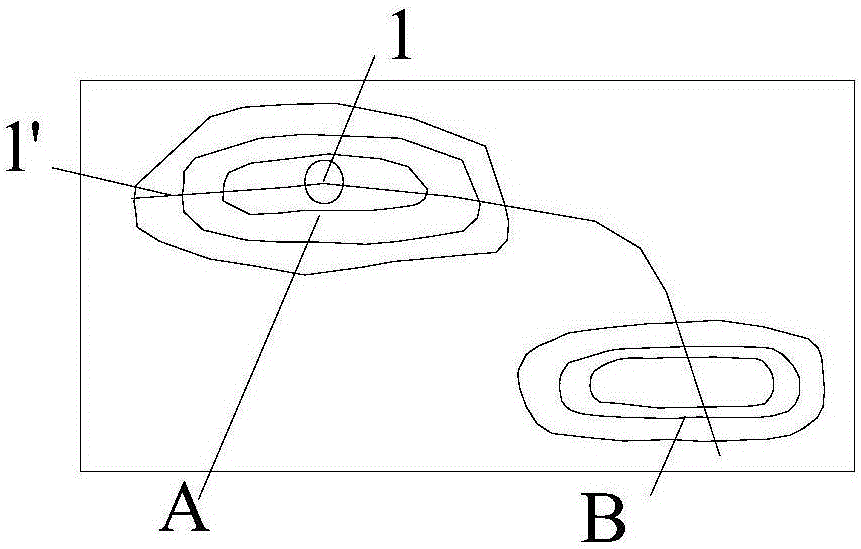

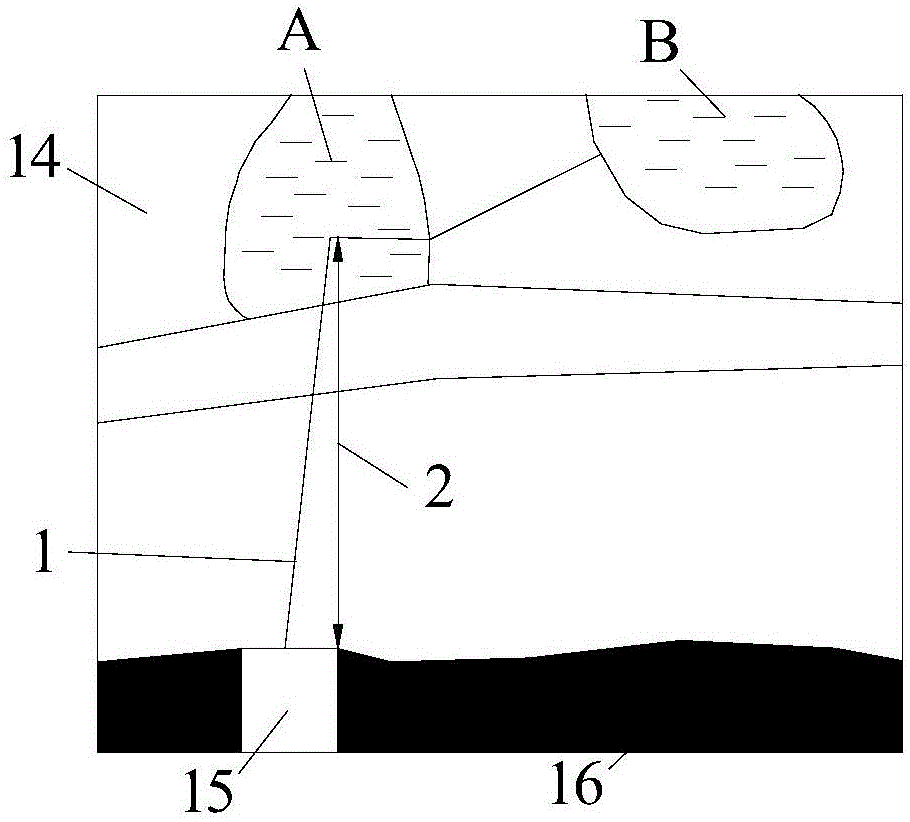

Roof water draining method based on directional drilling technique

ActiveCN106285776AIncrease water richness detectionIncrease the lengthDirectional drillingDrainageCoalGroundwater

Owner:SHAANXI COAL & CHEM TECH INST

Silicon integrated circuit operating at microwave frequencies and fabrication process

InactiveUS20070252177A1Reduced propagation lossTransistorSemiconductor/solid-state device detailsMicrowave applicationsParasitic capacitance

The invention relates to integrated circuits for microwave applications in the millimeter wavelength range (frequencies of around 50 GHz). To improve the performance of the microwave transmission lines in the circuit, a structure of conducting vias between a transmission line and a conducting zone is proposed. The vias are formed in apertures in a benzocyclobutene layer. These apertures are larger at their base than the conducting zones. The transmission line descends into the aperture but does not come back up over the edges of the aperture. The parasitic capacitances with the substrate at the point of contact are minimized.

Owner:COMMISSARIAT A LENERGIE ATOMIQUE ET AUX ENERGIES ALTERNATIVES +1

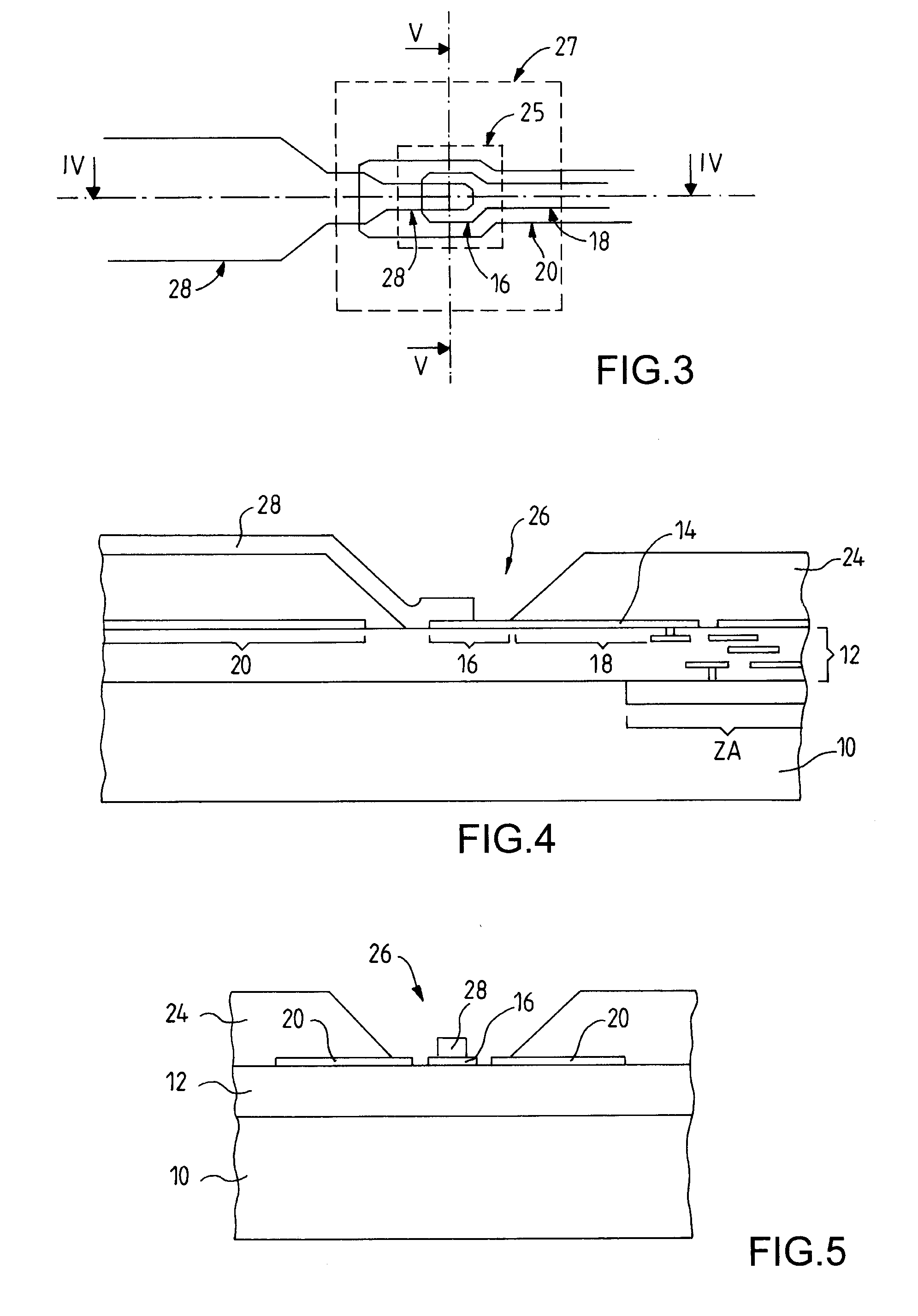

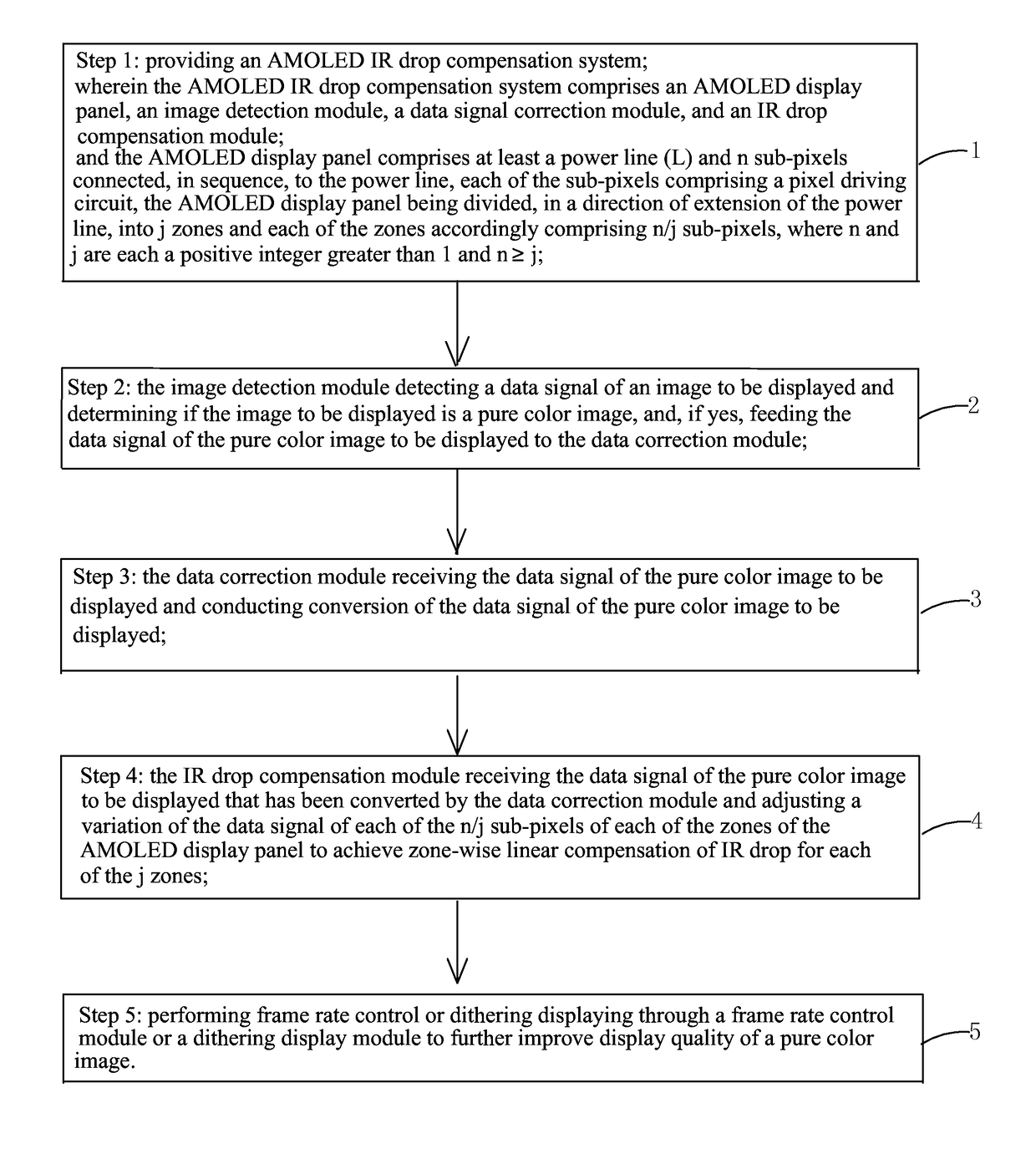

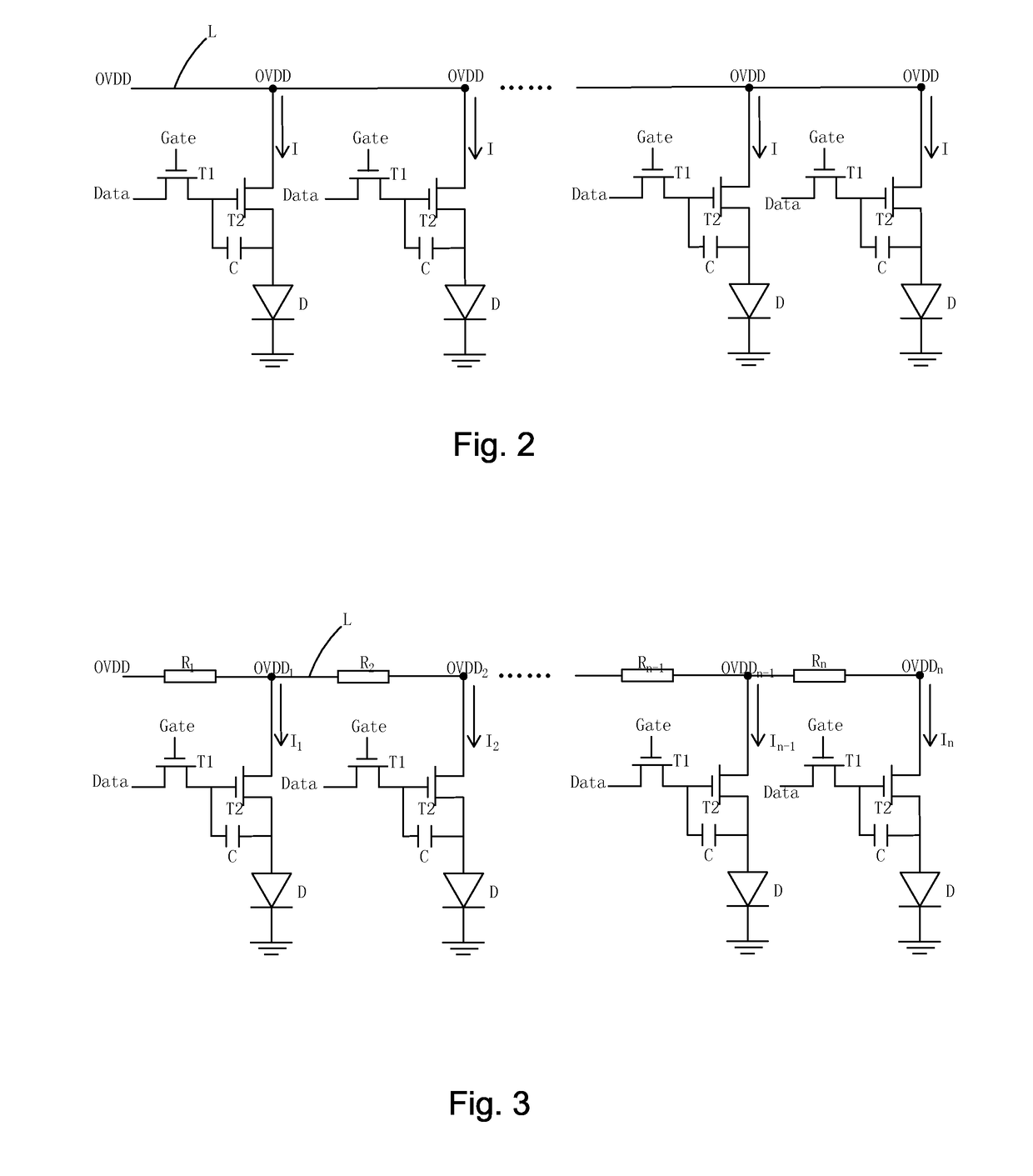

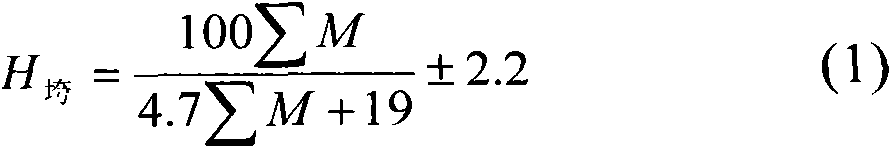

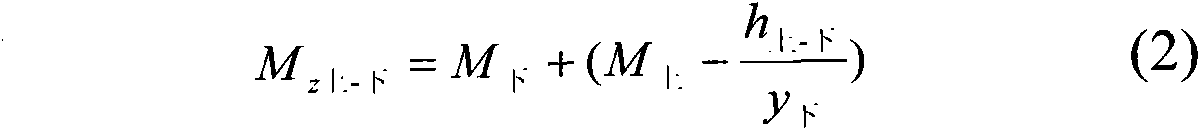

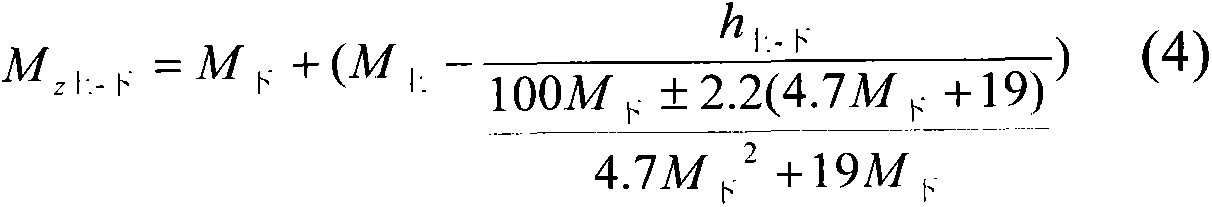

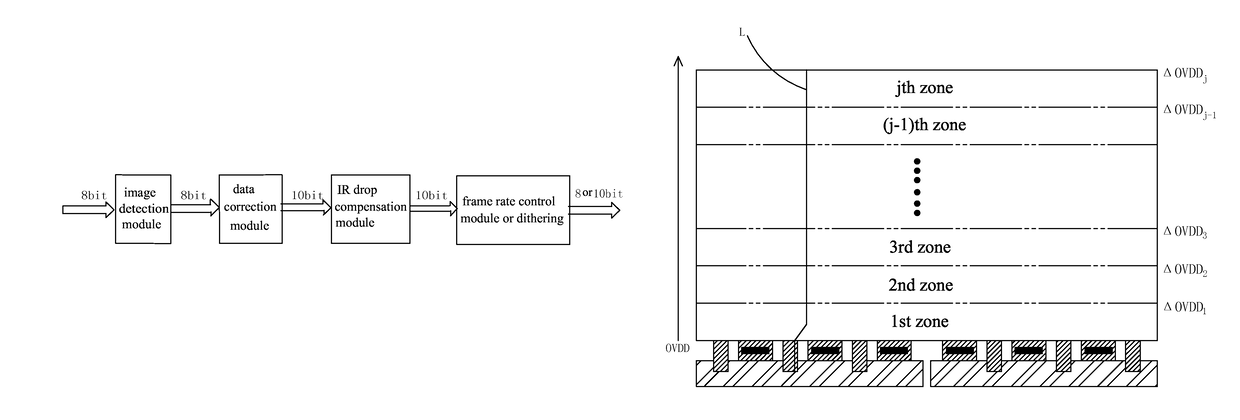

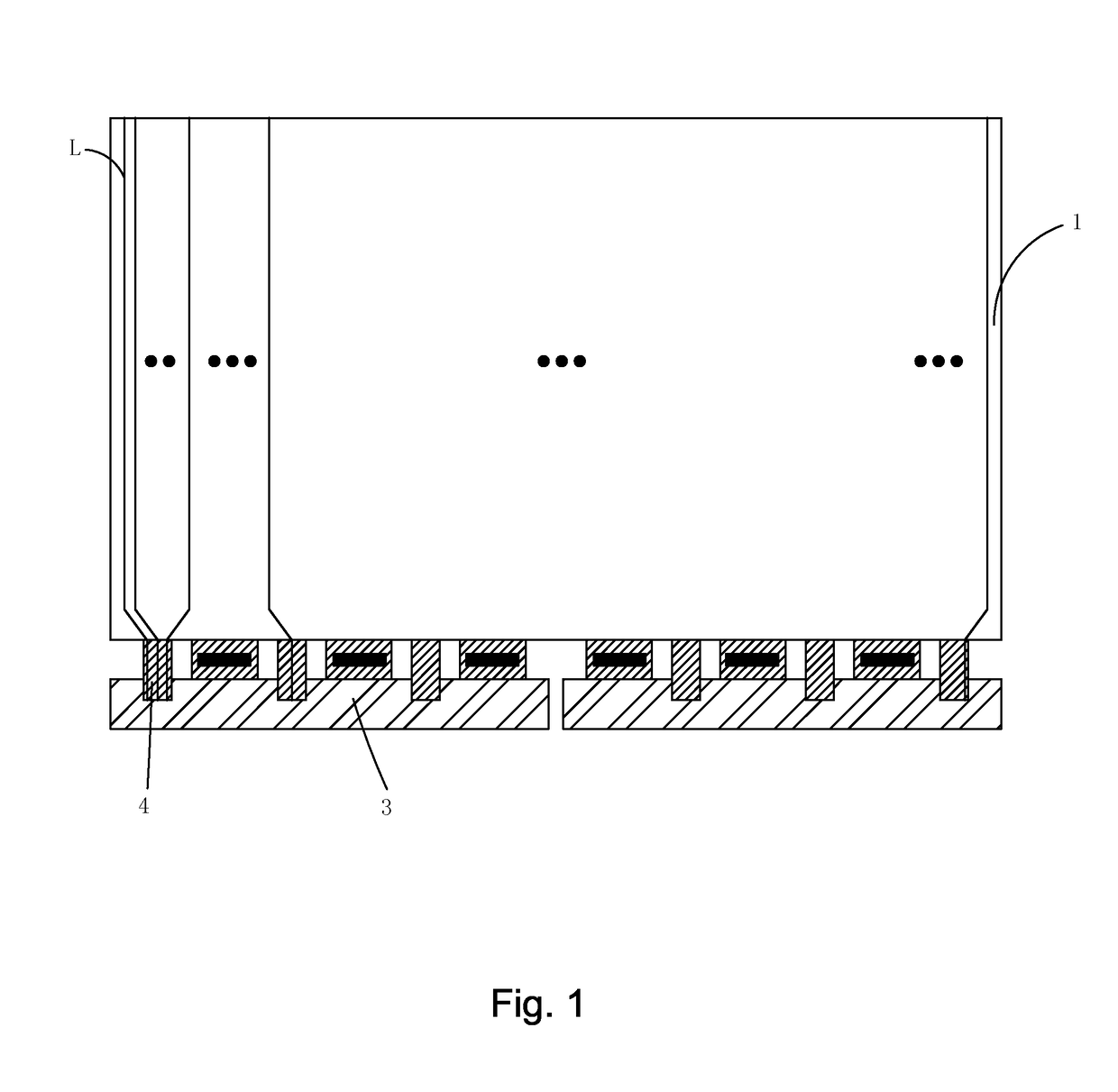

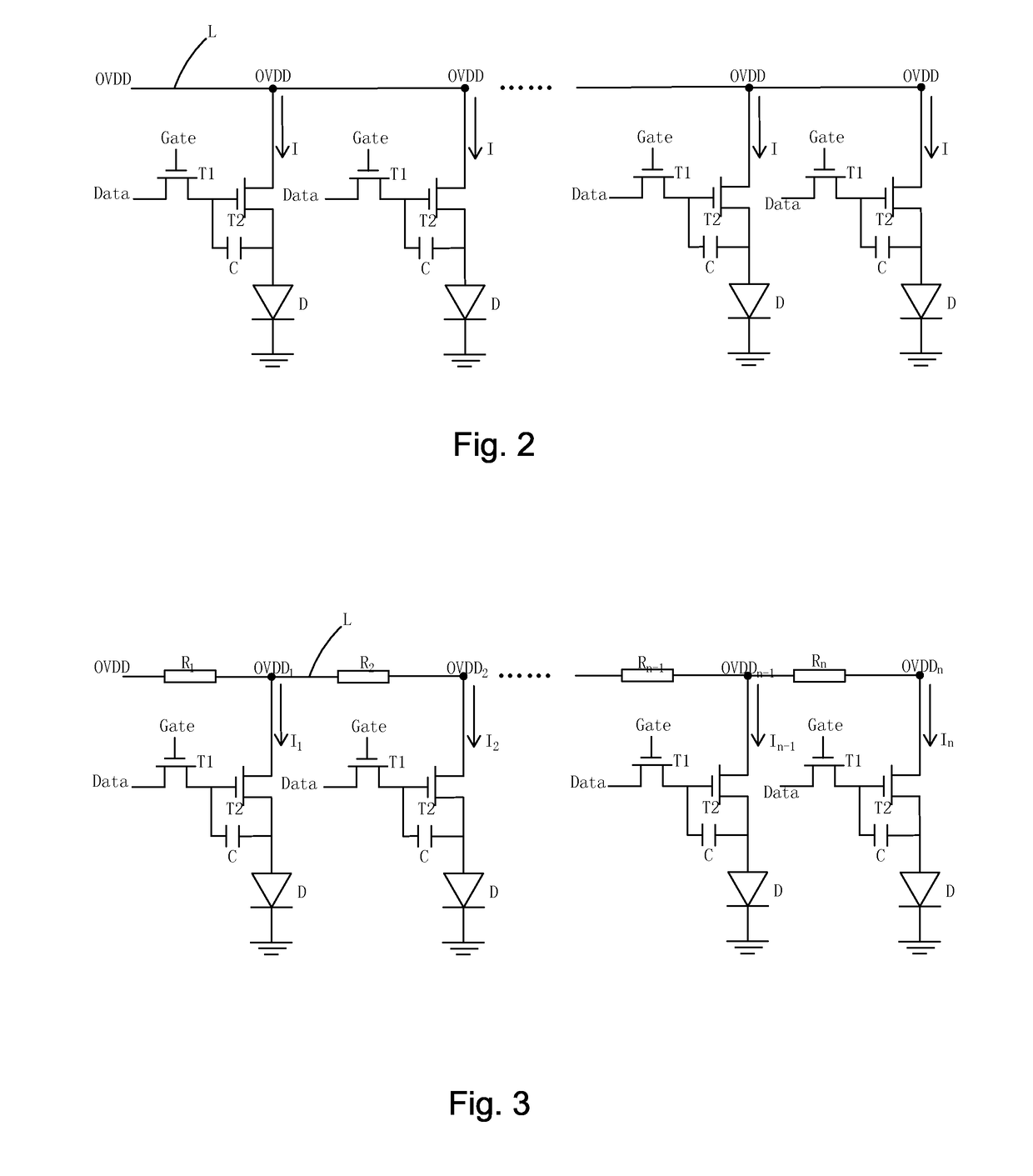

Amoled ir drop compensation system and method

ActiveUS20170140705A1Effective compensationImprove display qualityStatic indicating devicesColor imageImaging quality

The present invention provides an AMOLED IR drop compensation system and method. The AMOLED IR drop compensation system includes an AMOLED display panel that is divided into a plurality of zones, an image detection module, a data signal correction module, and an IR drop compensation module and may achieve zone-wise linear compensation for IR drop. The AMOLED IR drop compensation method includes dividing an AMOLED display panel in a direction of extension of a power line into a plurality of zones, applying an image detection module to detect a data signal of an image to be displayed and determine if the image to be displayed is a pure color image, applying a data correction module to convert the data signal of a pure color image to be displayed, and applying an IR drop compensation module to conduct zone-wise linear IR drop compensation for each of the plurality of zones by adjusting the variation of the data signal of each of the sub-pixels of each of the zones of the AMOLED display panel. The present invention can effectively compensate IR drop and overcome the problem of the image quality being not homogeneous caused by IR drop when an AMOLED display panel is displaying a pure color image.

Owner:SHENZHEN CHINA STAR OPTOELECTRONICS TECH CO LTD

Method for distinguishing ultra-close coal seam/group

The invention discloses a method for distinguishing an ultra-close coal seam / group. The method includes the steps of obtaining geographic information of related coal seams according to mine practical surveys; taking a lower coal seam as a single coal seam according to obtained parameters of the related coal seams and calculating the heights of caving zones of the coal seams according to formulas provided by related rules; choosing different calculation methods of comprehensive mining thicknesses according to ratios; according to the comprehensive mining thicknesses obtained through calculation, choosing an appropriate calculation formula of water conducted zone heights in combination with practical geographic conditions of a mine, and therefore calculating the water conducted zone heights of two coal seams. The method provides applicable conditions of the calculation formula of the water conducted zone heights of the ultra-close coal seam when the height of the caving zone of the lower coal seam enters a mining range of an upper coal seam, reflects the quantitative relation of the mining thickness of the upper coal seam, the mining thickness of the lower coal seam and vertical distances of the coal seams, and provides bases and reference for choices of calculation methods of the ultra-close coal seam and the water conducted zone of the ultra-close coal seam.

Owner:SHANDONG UNIV OF SCI & TECH

Repairing method for split sealing surface of pressure resistant vessel

The invention discloses a repairing method for a split sealing surface of a pressure resistant vessel. The pressure resistant vessel mainly comprises an upper half cylinder and a lower half cylinder, which are connected together by a fastening bolt; and the split sealing surface is formed between the upper half cylinder and the lower half cylinder. The repairing method comprises the following steps: (1) checking the gap of the split sealing surfaces between the upper half cylinder and the lower half cylinder, and completing the record; (2) taking the sealing surface of the upper half cylinder as the standard; determining a surfacing zone on the sealing surface of the lower half cylinder and the corresponding surfacing thickness according to the checked data; (3) cleaning the surfacing zone on the sealing surface of the lower half cylinder, conducting the zoned and segmented surfacing, and forming a grid-shaped surfacing layer on the sealing surface of the lower half cylinder; (4) polishing the surfacing layer, and reserving a scraping allowance; and (5) conducting zoned scraping to enable the sealing surface of the upper half cylinder and the sealing surface of the lower half cylinder with the surfacing layer to form a split sealing surface meeting the design requirement. The repairing method can eliminate the gap between the sealing surfaces of the upper half cylinder and the lower half cylinder reliably to achieve a good sealing effect.

Owner:DONGFANG TURBINE CO LTD

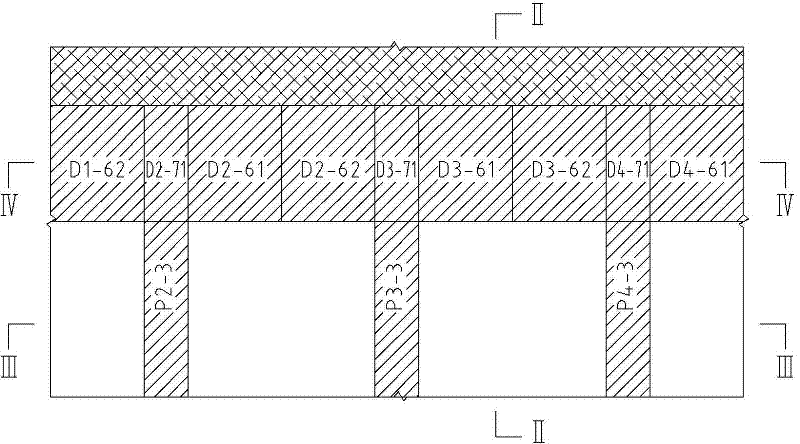

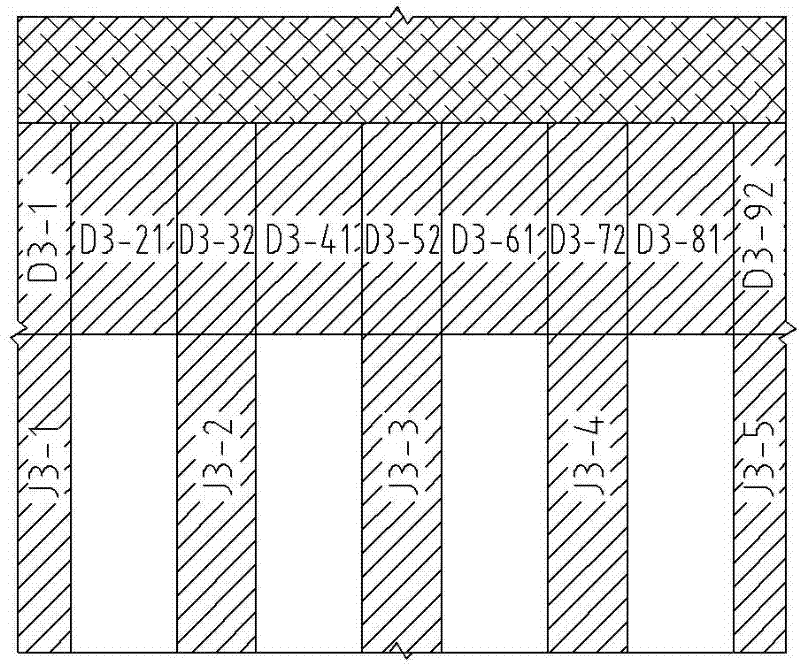

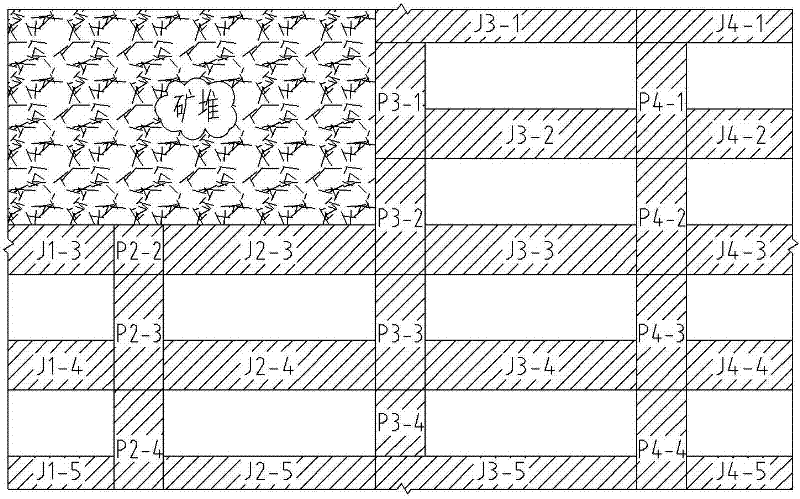

Three-dimensional zoned collaborative caving mining method for pillar groups

InactiveCN102359377AAvalanche efficientAvoid destructionUnderground miningBlastingEngineeringStoping

The invention discloses a three-dimensional zoned collaborative caving mining method for pillar groups. The method comprises that: taking stability significantly correlated pillar groups in a large and empty environment as a collaborative caving unit, conducting zoning within a three-dimensional solid of the collaborative caving unit, with each zone as a blasting zone with an independent free surface and a compensation space; carrying out blasting for one time to all zones within the caving unit through short-delay blasting or simultaneous blasting between zones to realize collaborative caving; making the blasting directions of all zones form mutual extrusion, with a continuous or discontinuous blasting initiation sequence in space among zones; leaving the blasting initiation sequences and blasting directions of blast holes within different zones mutually uncorrelated. The method of the invention is suitable for collaborative stoping of a plurality of pillars and treatment of multiple empty zones in a big and empty zone environment. The method provided in the invention completes empty zone treatment and pillar stoping in one step, thus providing a safe, efficient, productive and low-cost solution to underground mining of pillar groups in a big and empty zone environment.

Owner:CHINA MINMETALS CHANGSHA MINING RES INST

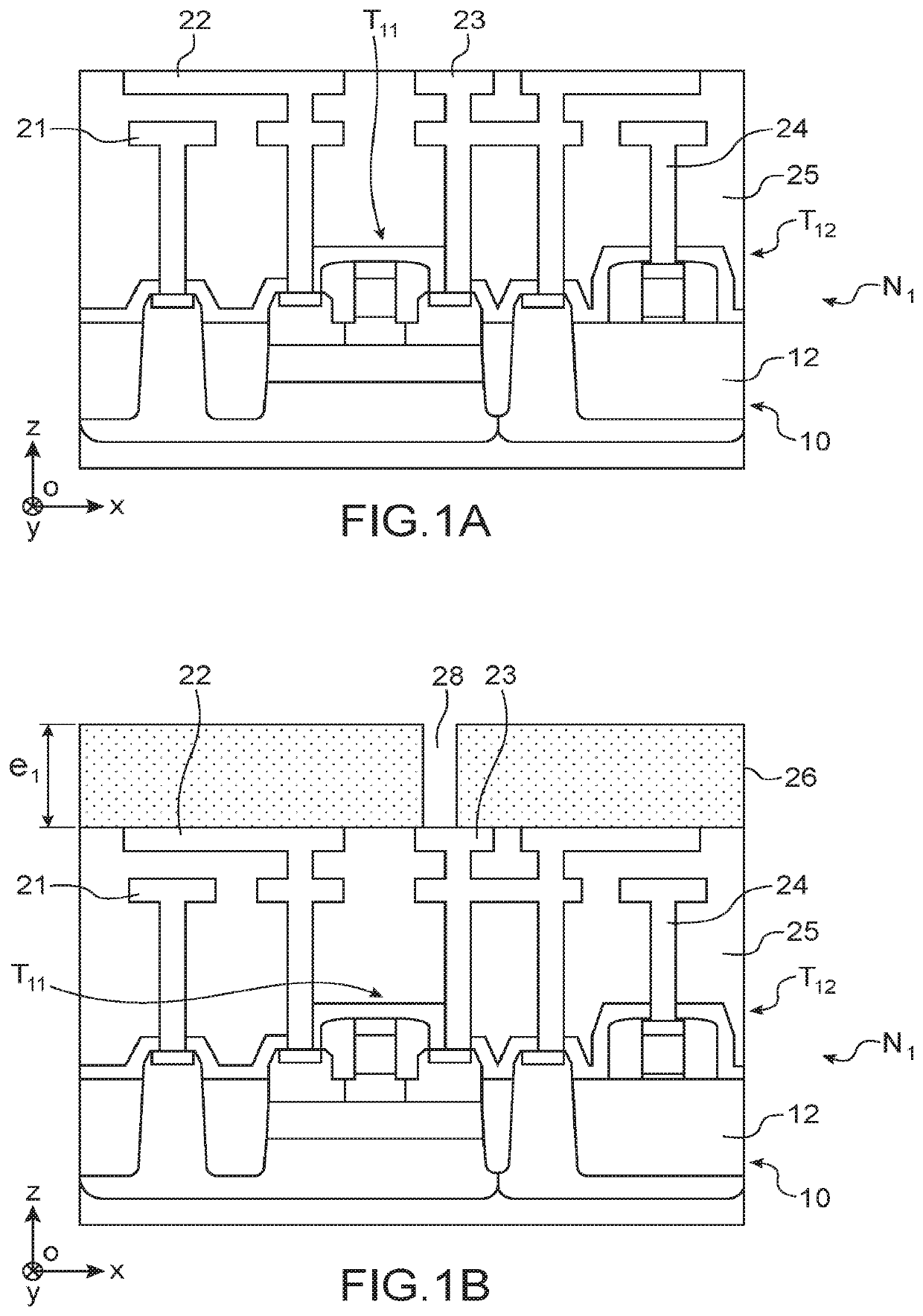

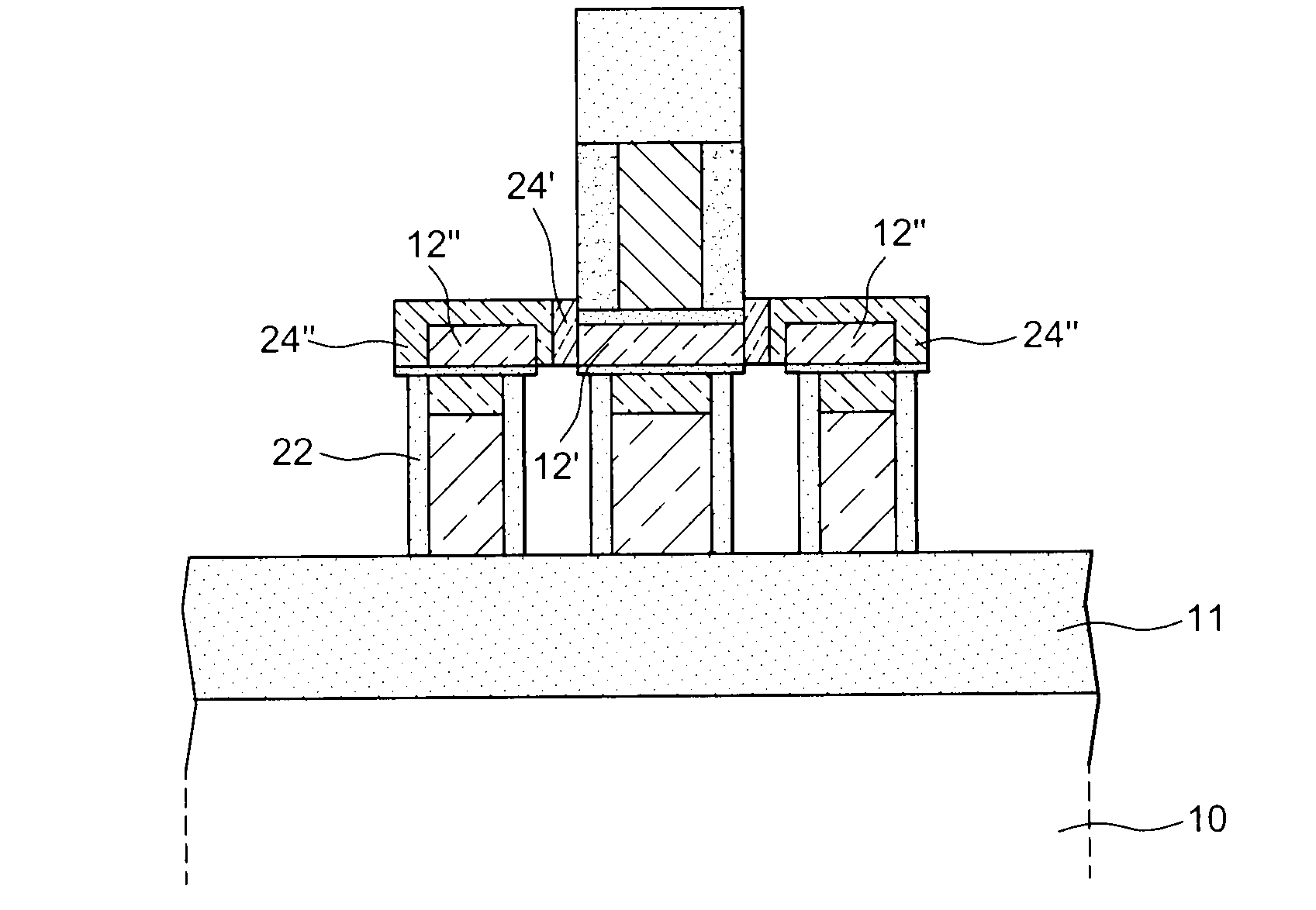

Internal via with improved contact for upper semi-conductor layer of a 3D circuit

ActiveUS20190371671A1Short durationReduce resistanceSemiconductor/solid-state device detailsSolid-state devicesElectrical conductorSemiconductor structure

Connection structure for microelectronic device with superposed semi-conductor layers comprising a conductor via that connects a lower face of an upper semi-conductor layer and an underlying conducting zone, said connection structure further comprising a silicide zone in contact with a lower face or with an inner face of the layer of the upper semi-conductor layer.

Owner:COMMISSARIAT A LENERGIE ATOMIQUE ET AUX ENERGIES ALTERNATIVES

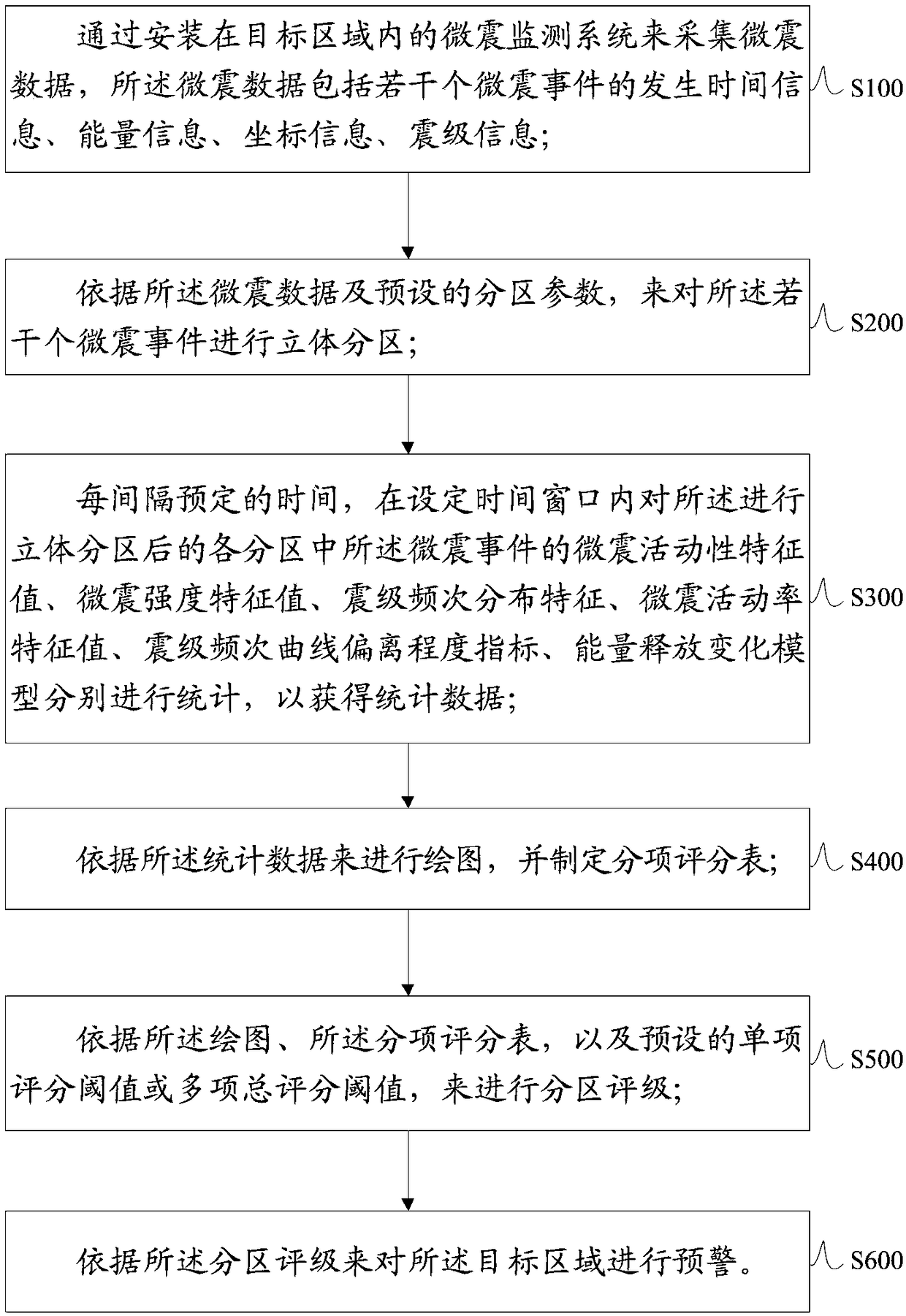

Method for mine disaster automatic zoning and early warning based on microseismic information

ActiveCN109441546AImprove securityImprove the effect of early warningMining devicesAlarmsMonitoring systemDistribution characteristic

The invention discloses a method for mine disaster automatic zoning and early warning based on microseismic information, and belongs to the technical field of microseismic early warning. The method includes the steps that microseismic data are collected through a microseismic monitoring system, microseismic data include occurrence time information, energy information, coordinate information and magnitude information of a plurality of microseismic events; according to the microseismic data and preset zoning parameters, the microseismic events are subjected to three-dimensional zoning; at everypredetermined time interval, in a set time window, microseismic activity characteristic values, microseismic intensity characteristic values, magnitude frequency distribution characteristics, microseismic activity rate characteristic values, magnitude frequency curve deviation degree indexes and energy release change models of the microseismic events in each zoning are statistically analyzed correspondingly to obtain statistic data to plot, an itemized rating scale and a preset single score threshold or multiple total score threshold are developed to conduct zoning rating and early warning toa target zone. The method for mine disaster automatic zoning and early warning based on the microseismic information achieves the technical effects that safety is improved, operation is convenient, and the early warning effect is improved.

Owner:湖北海震科创技术有限公司 +2

Method for producing Si.sub.1-yGe.sub.y based zones with different contents in Ge on a same substrate by condensation of germanium

ActiveUS7972971B2Solid-state devicesMaterial analysis by electric/magnetic meansComputer scienceSemiconductor

The disclosure relates to a method for producing a microelectronic device including a plurality of Si1-yGey based semi-conducting zones (where 0<y≦̸1) which have different respective Germanium contents, comprising the steps of: a) formation on a substrate covered with a plurality of Si1-yGey based semi-conducting zones (where 0<x<1 and x<y) and identical compositions, of at least one mask comprising a set of masking blocks, wherein the masking blocks respectively cover at least one semi-conducting zone of the said plurality of semi-conducting zones, wherein several of said masking blocks have different thicknesses and / or are based on different materials, b) oxidation of the semi-conducting zones of the said plurality of semi-conducting zones through said mask.

Owner:COMMISSARIAT A LENERGIE ATOMIQUE ET AUX ENERGIES ALTERNATIVES +1

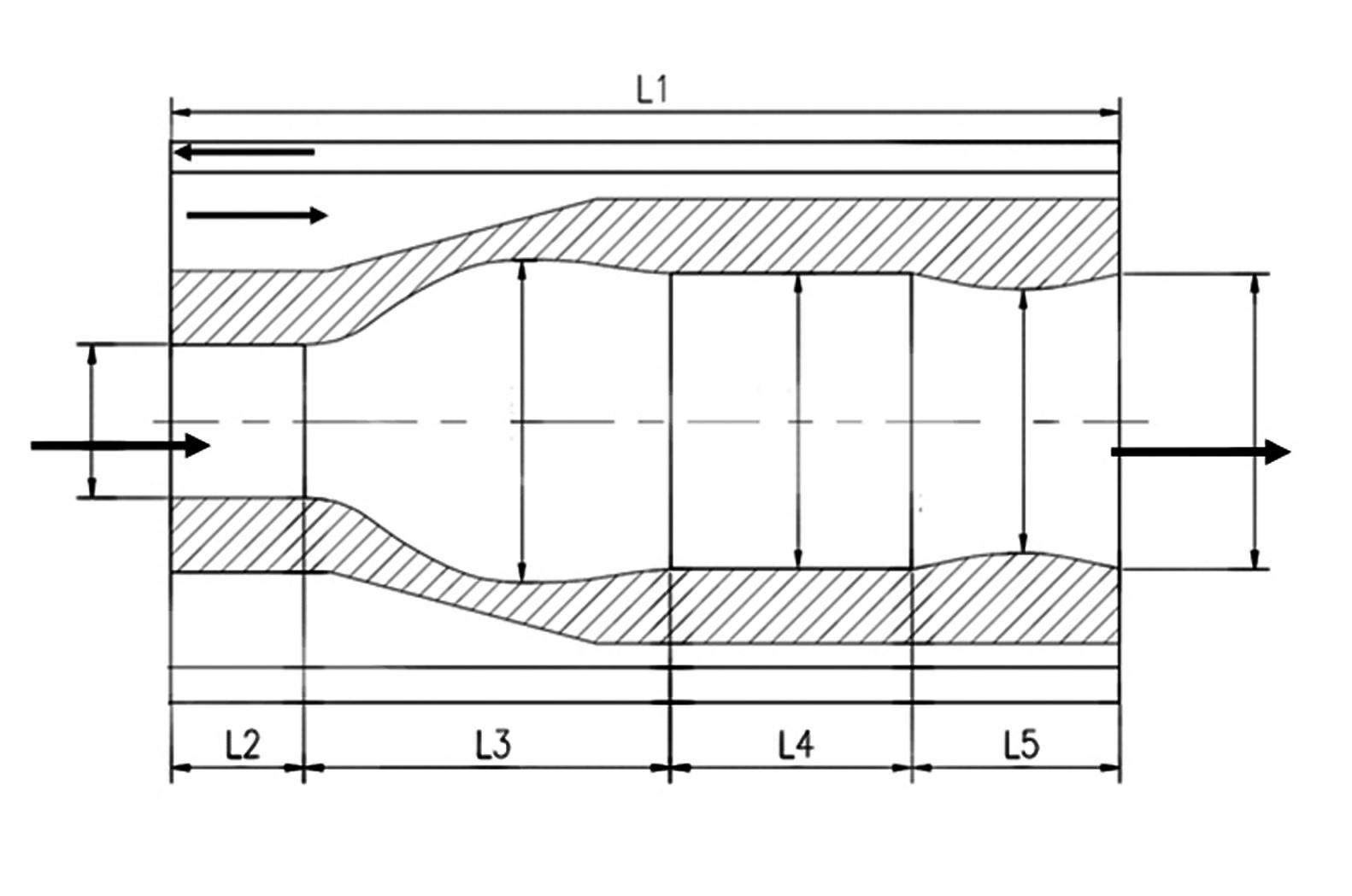

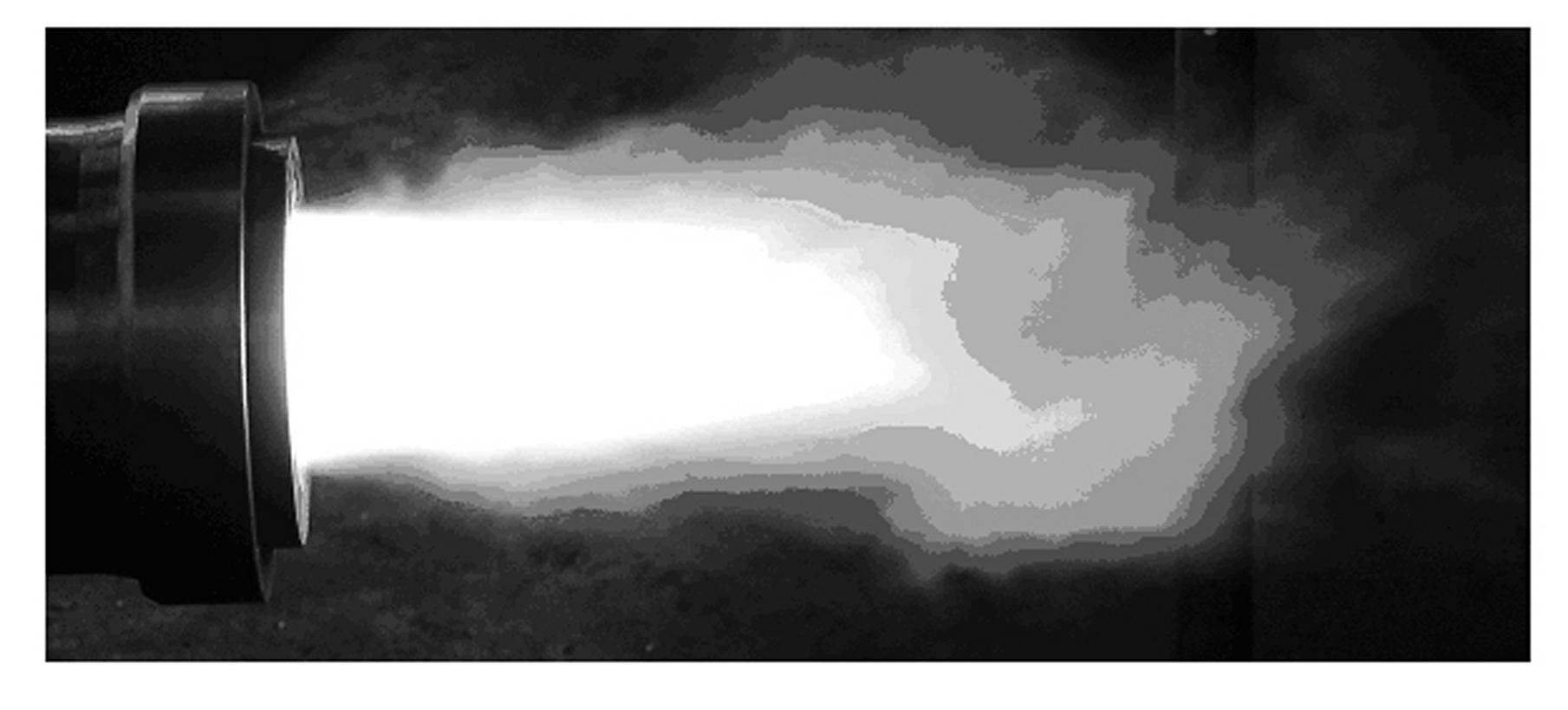

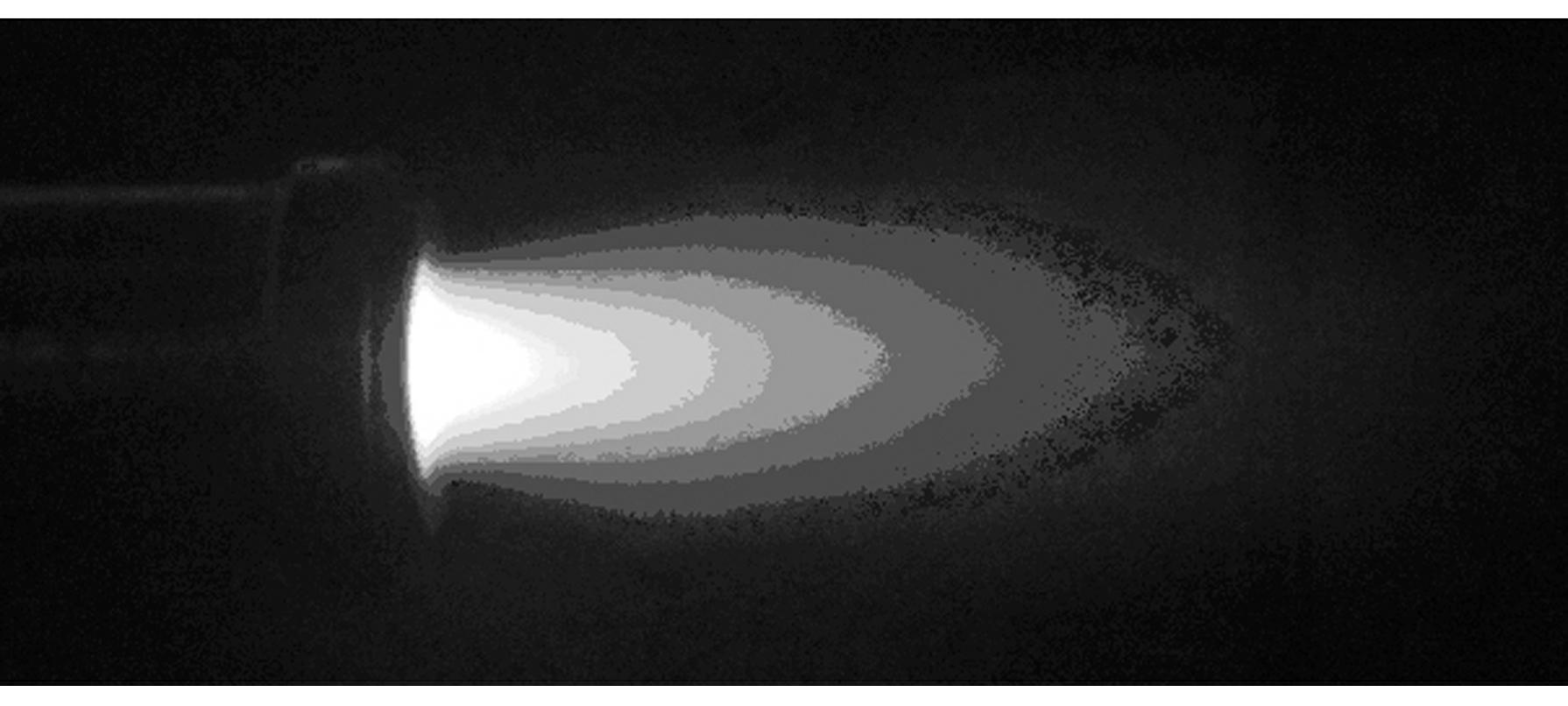

Multi-cavity plasma generator anode

The invention provides a multi-cavity plasma generator anode, which comprises a compression cavity, a stable combustion cavity, a conduction flow cavity and an accelerating cavity, which are connected in succession; the compression cavity is used to compress plasmas generated by a cathode; the stable combustion cavity can meet the requirement of plasma expansion; the conduction flow cavity provides a good electrically conductive path for conduction electrons; the accelerating cavity is a double-parabola structure formed by an upper-open parabola and a lower-open parabola; and the compression section is used to compress plasmas and improve plasma density, and the accelerating section is used to reduce the resistance of plasmas jetting form the leading end of the anode and increase plasma jetting velocity. The multi-cavity plasma generator anode provided by the invention is different from the traditional plasma generator anode, which adopts a first-compression-and-then-expansion type nozzle. In the invention, a unique multi-cavity anode construction is designed according to the expansion property of plasmas, and therefore the shortcoming of the traditional anode that the anode life is shortened due to too fast ablation rate resulting from the overlap of a conducting zone and an electric arc combustion zone is overcome.

Owner:WUHAN TIANHE TECH

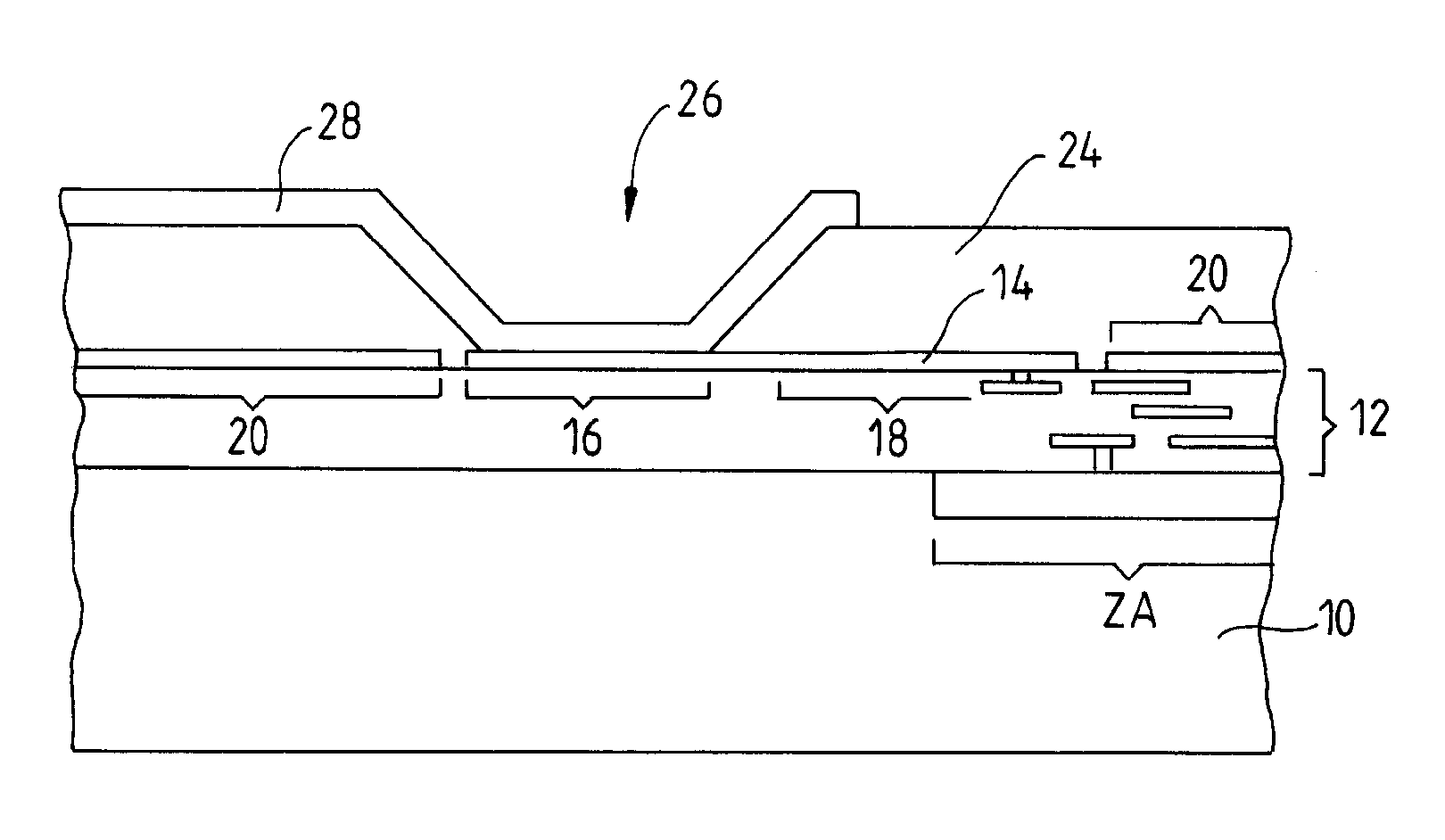

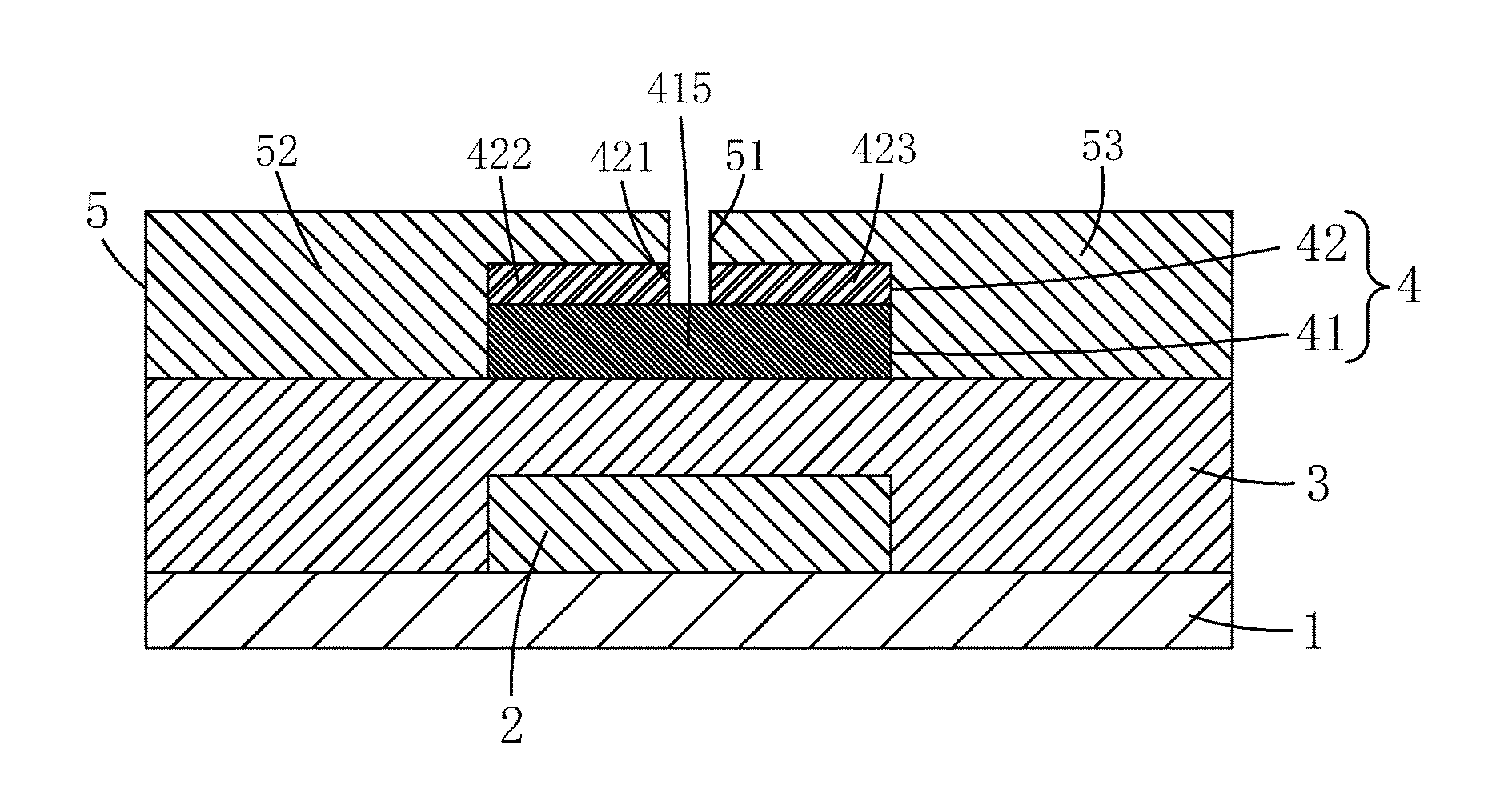

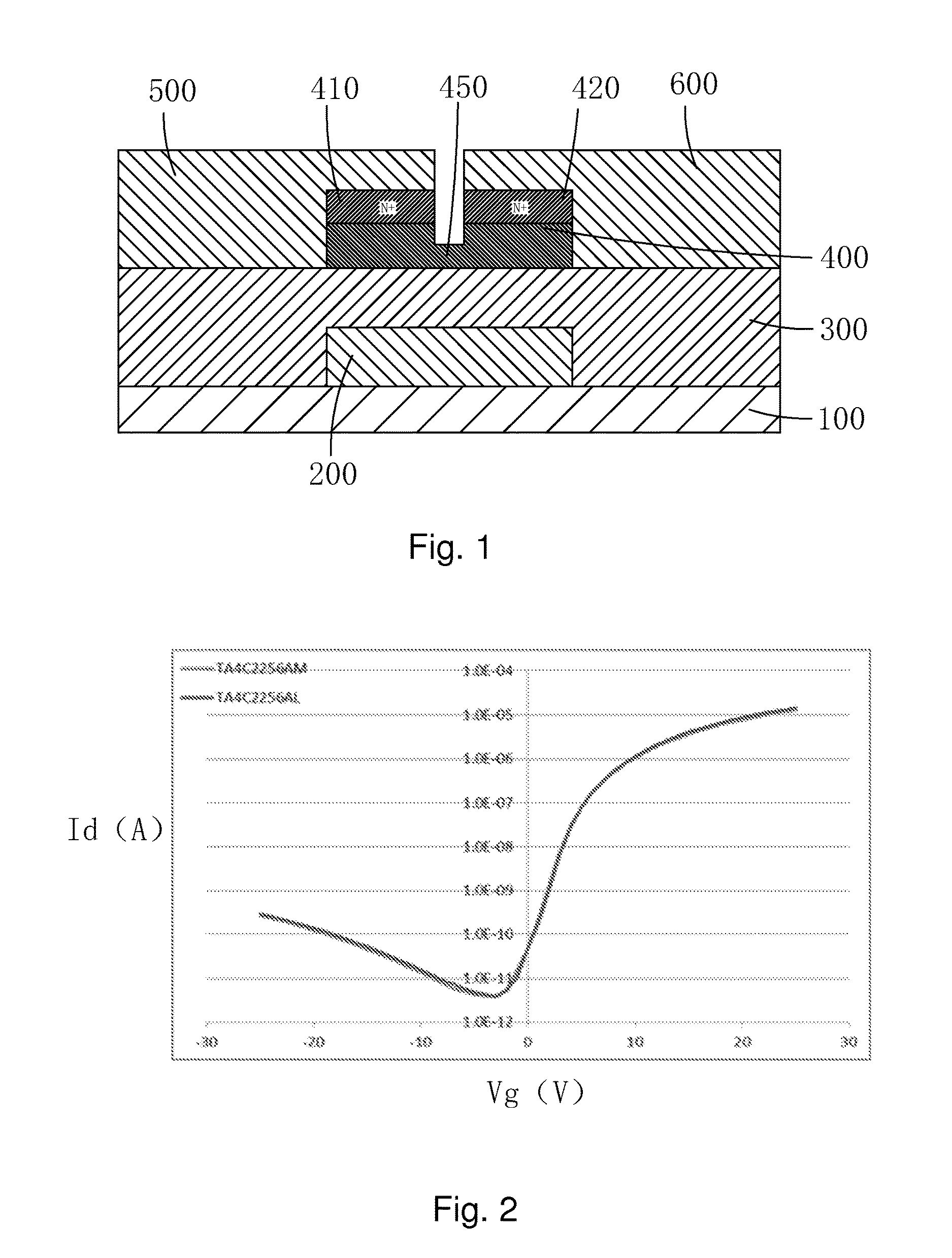

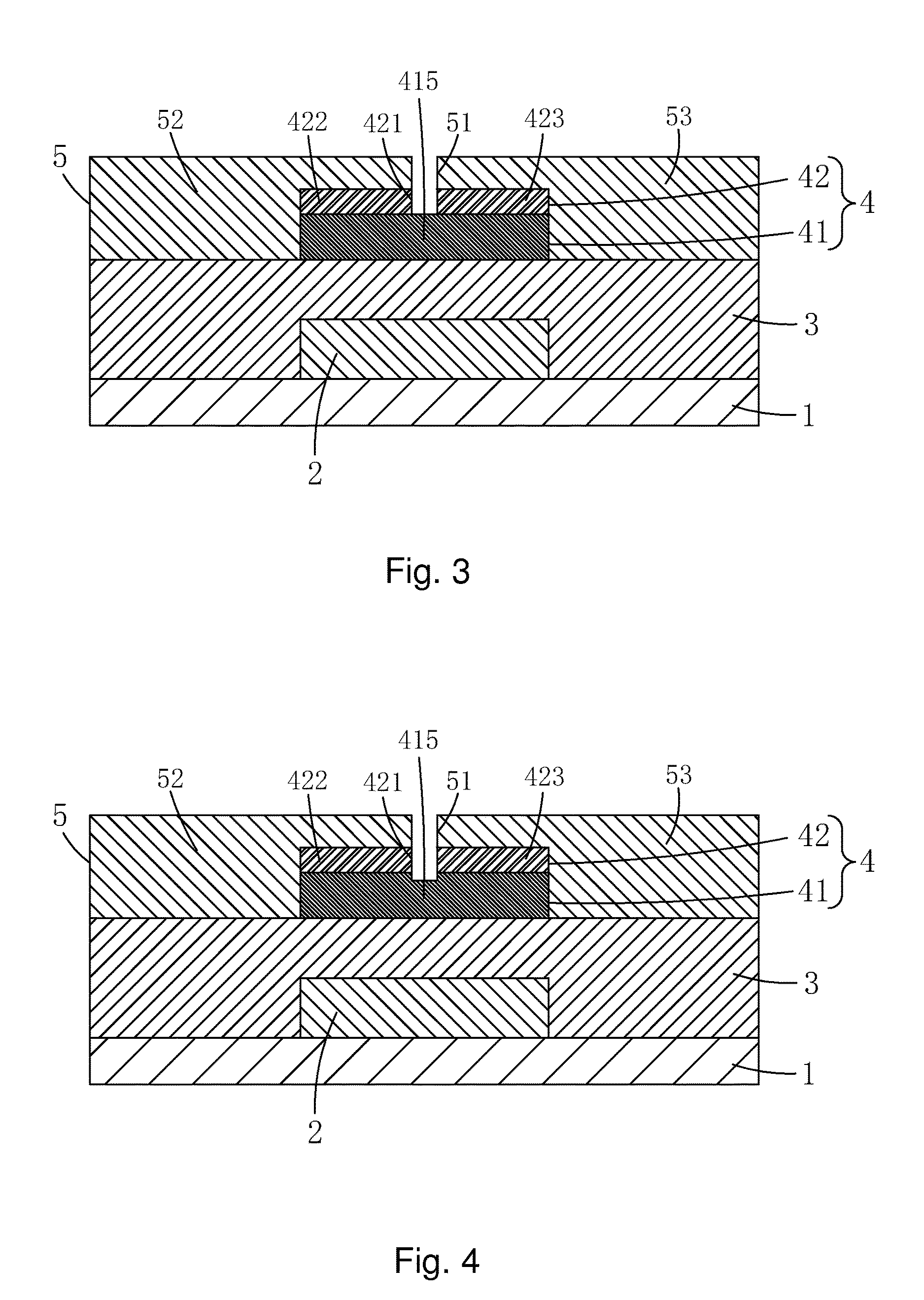

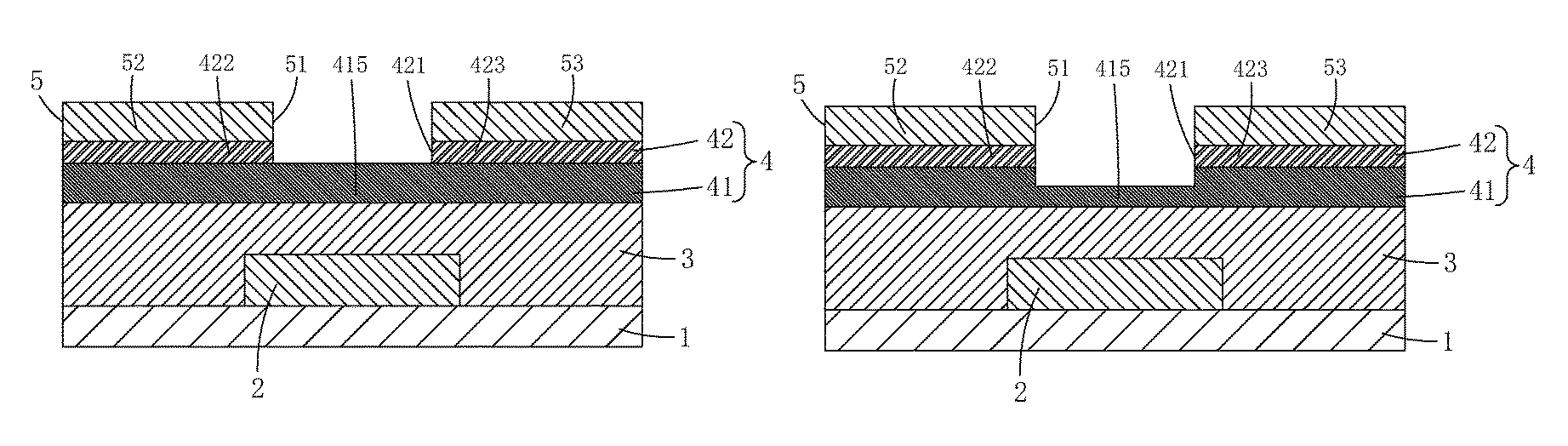

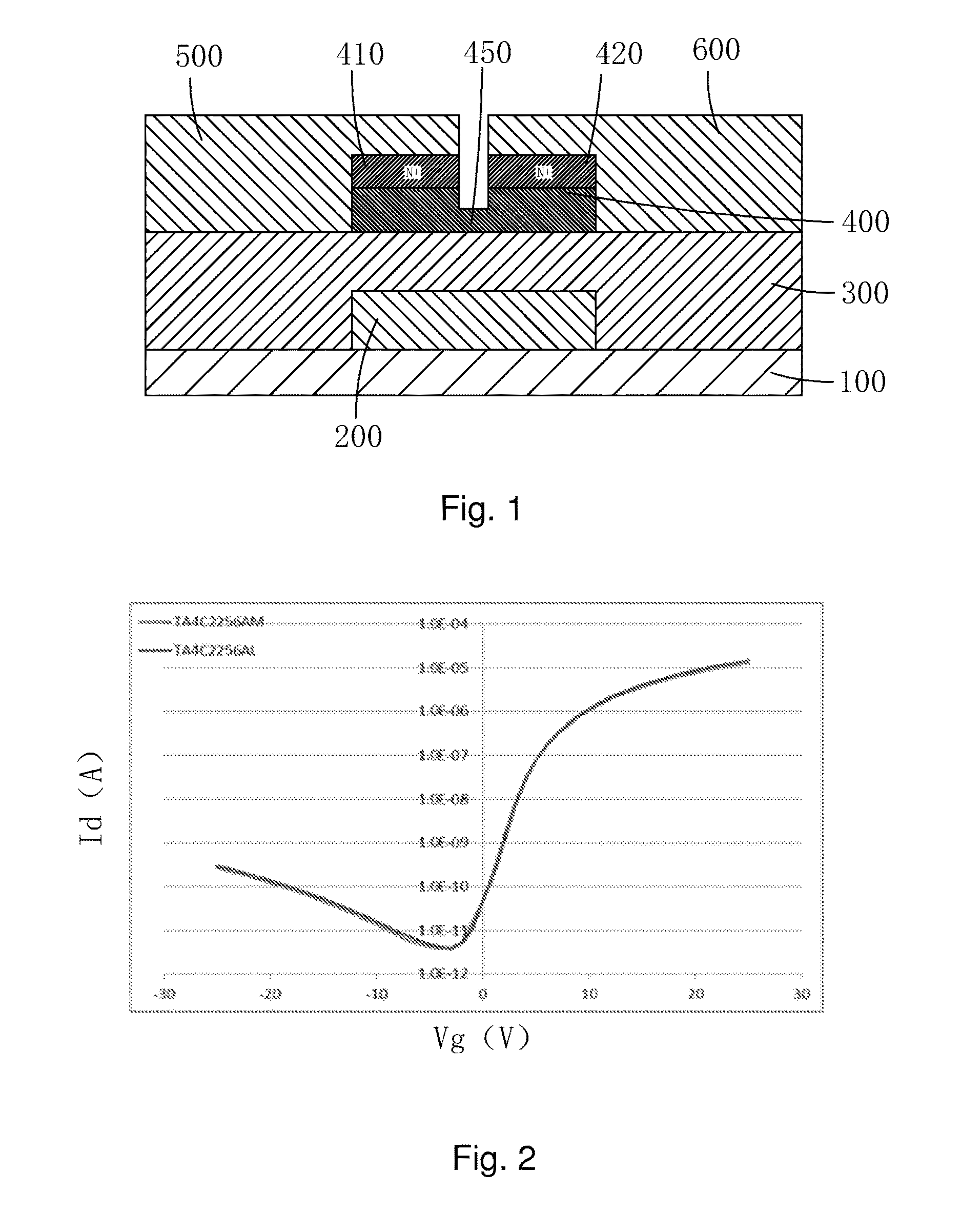

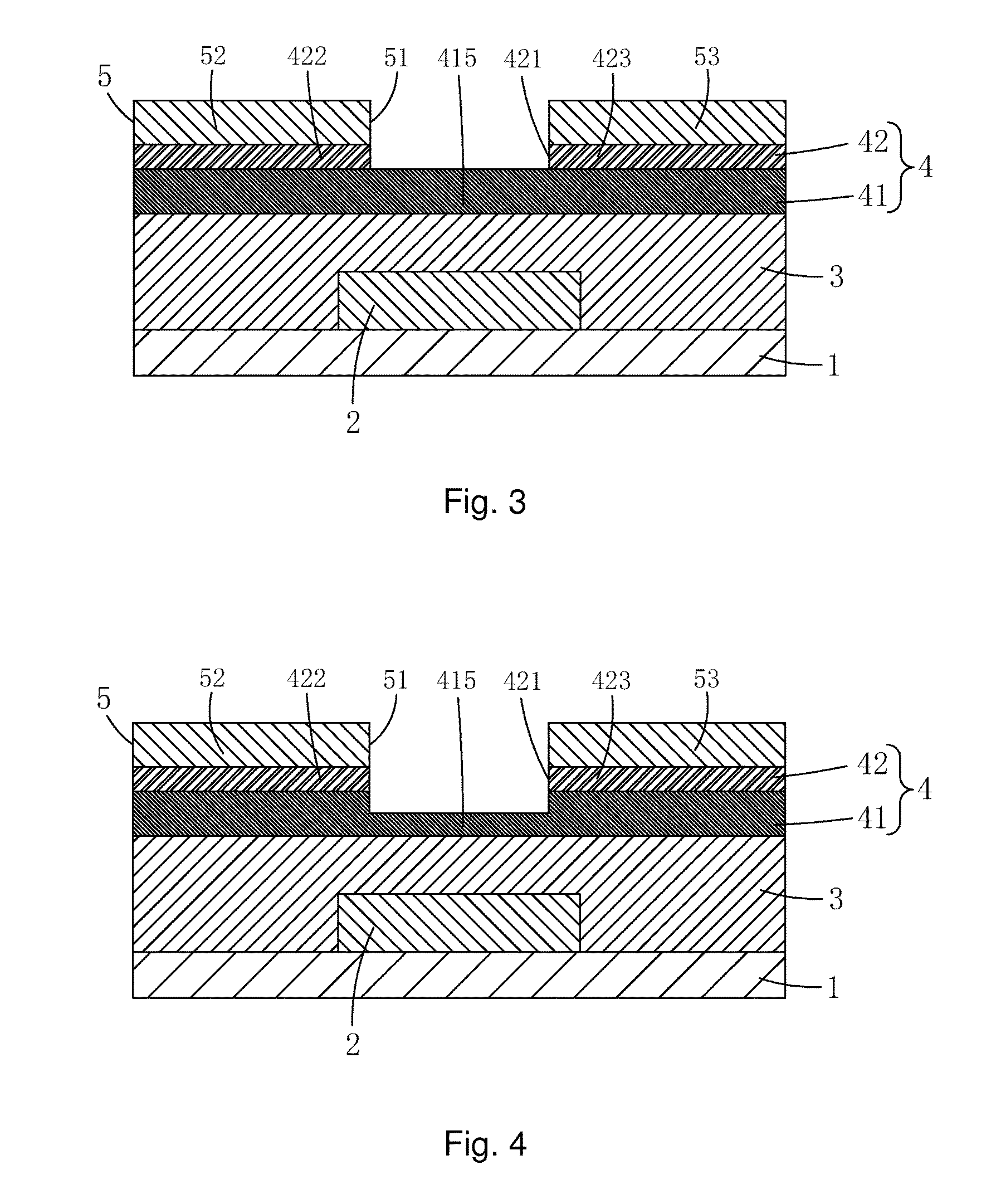

TFT substrate structure and manufacturing method thereof

ActiveUS20170018651A1Improve current efficiencyLower the barrierTransistorOhmic contactAmorphous silicon

The present invention provides a TFT substrate structure and a manufacturing method thereof. A metal oxide semiconductor layer is formed on an amorphous silicon layer to replace an N-type heavily-doped layer. The potential barrier between the amorphous silicon layer and metal layer is relatively low, making it possible to form an ohmic contact and thus increasing current efficiency, without the need of doping other ions to form the N-type heavily-doped layer. Further, the metal oxide semiconductor layer comprises numerous defects that trap holes so that during the operation of the TFT, even a great negative voltage is applied to the gate terminal to thus form a hole conducting channel, the holes may hardly move from the source / drain terminals through the metal oxide semiconductor layer and the semiconductor layer to reach the conducting channel and consequently, the current leakage issue occurring in a hole conducting zone of a conventional TFT substrate structure can be improved and severe bending of the hole current curve and poor reliability are also improved.

Owner:SHENZHEN CHINA STAR OPTOELECTRONICS TECH CO LTD

Laser scanning method for coaxially feeding powder

ActiveCN110625114AReduce distortionReduce the chance of crackingAdditive manufacturing apparatusIncreasing energy efficiencyManufacturing technologyLaser scanning

The invention relates to the technical field of additive manufacturing, and discloses a laser scanning method for coaxially feeding powder. The laser scanning method comprises the steps of obtaining layout files of sections of a to-be-processed workpiece layer by layer and identifying the layout files, in the area of each layer of layout file, conducting zoning in the form that a same kind of polygons is uniformly arranged, planning a scanning path in each zone, and then deleting zoning lines of the zones; conducting laser scanning on each zone in a negative lapping way by using an internallynon-overlapped isometric spiral scanning path; conducting border scanning on each layer of layout file. After zoning, heat is dispersed, energy is prevented from being too concentrated, and the deformation and cracking probability of a component is reduced. By using the isometric spiral scanning path, the problems are solved that in the prior art, reciprocating backfilling scanning is conducted inthe same layer, short edges are mutually overlapped, and the flatness is poor, and the post machining allowance is reduced.

Owner:TSC LASER TECH DEV BEIJING CO LTD

AMOLED IR drop compensation system and method

ActiveUS9892686B2Effective compensationImprove display qualityStatic indicating devicesColor imageImaging quality

The present invention provides an AMOLED IR drop compensation system and method. The AMOLED IR drop compensation system includes an AMOLED display panel that is divided into a plurality of zones, an image detection module, a data signal correction module, and an IR drop compensation module and may achieve zone-wise linear compensation for IR drop. The AMOLED IR drop compensation method includes dividing an AMOLED display panel in a direction of extension of a power line into a plurality of zones, applying an image detection module to detect a data signal of an image to be displayed and determine if the image to be displayed is a pure color image, applying a data correction module to convert the data signal of a pure color image to be displayed, and applying an IR drop compensation module to conduct zone-wise linear IR drop compensation for each of the plurality of zones by adjusting the variation of the data signal of each of the sub-pixels of each of the zones of the AMOLED display panel. The present invention can effectively compensate IR drop and overcome the problem of the image quality being not homogeneous caused by IR drop when an AMOLED display panel is displaying a pure color image.

Owner:TCL CHINA STAR OPTOELECTRONICS TECH CO LTD

TFT substrate structure and manufacturing method thereof

ActiveUS9525070B1Improve current efficiencyReduce leakage currentTransistorOhmic contactAmorphous silicon

The present invention provides a TFT substrate structure and a manufacturing method thereof. A metal oxide semiconductor layer is formed on an amorphous silicon layer to replace an N-type heavily-doped layer. The potential barrier between the amorphous silicon layer and metal layer is relatively low, making it possible to form an ohmic contact and thus increasing current efficiency, without the need of doping other ions to form the N-type heavily-doped layer. Further, the metal oxide semiconductor layer comprises numerous defects that trap holes so that during the operation of the TFT, even a great negative voltage is applied to the gate terminal to thus form a hole conducting channel, the holes may hardly move from the source / drain terminals through the metal oxide semiconductor layer and the semiconductor layer to reach the conducting channel and consequently, the current leakage issue occurring in a hole conducting zone of a conventional TFT substrate structure can be improved and severe bending of the hole current curve and poor reliability are also improved.

Owner:SHENZHEN CHINA STAR OPTOELECTRONICS TECH CO LTD

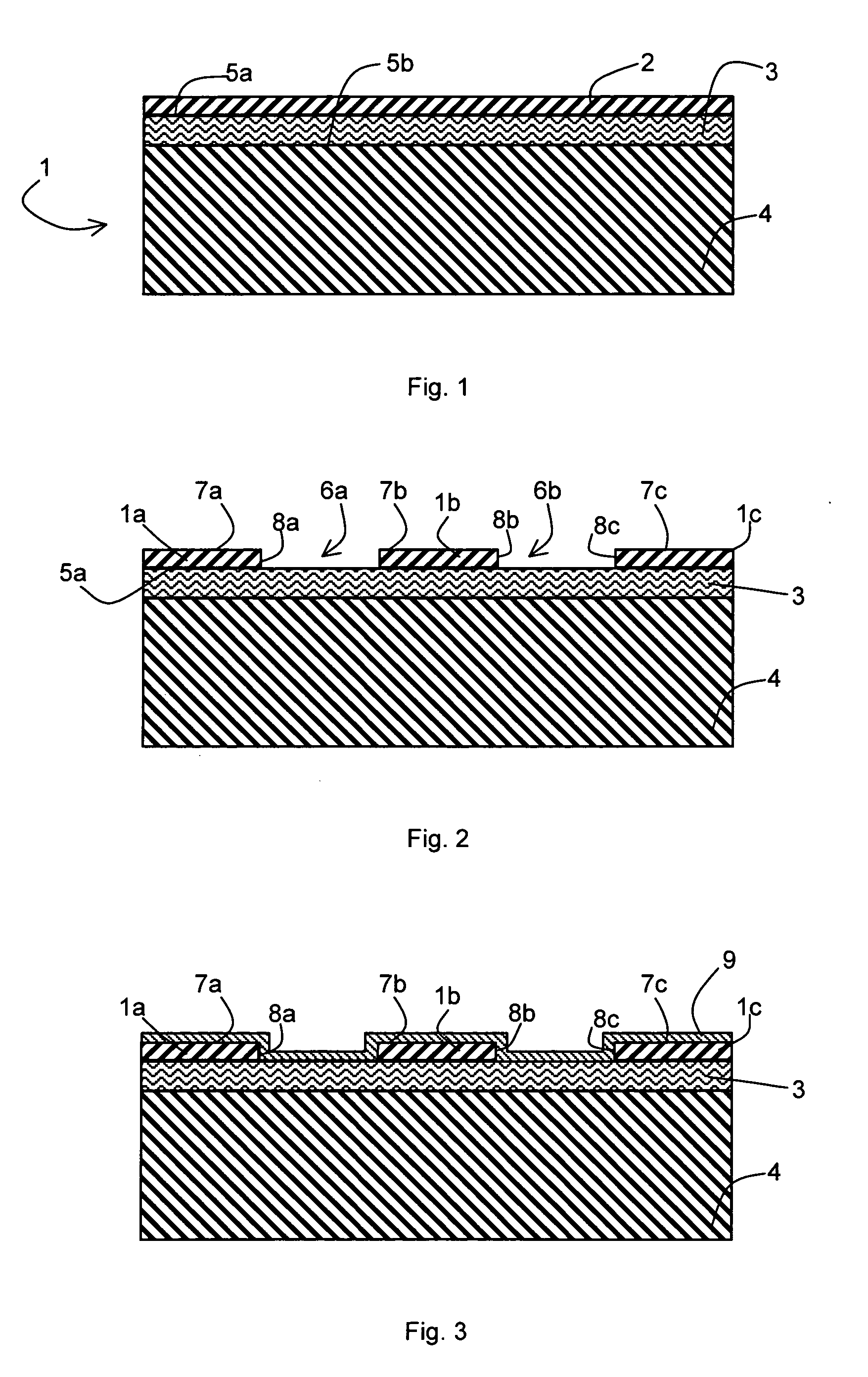

Method for producing distinct first and second active semi-conducting zones and use thereof for fabricating C-MOS structures

InactiveUS20070105315A1Easy to manufactureSolid-state devicesSemiconductor/solid-state device manufacturingSemiconductor materialsCrystal structure

A method according to the invention enables first and second active zones to be produced on a front face of a support, which said zones are respectively formed by first and second monocrystalline semi-conducting materials that are distinct from one another and preferably have identical crystalline structures. The front faces of the first and second active zones also present the advantage of being in the same plane. Such a method consists in particular in producing the second active zones by a crystallization step of the second semi-conducting material in monocrystalline form, from patterns made of second semi-conducting material in polycrystalline and / or amorphous form and from interface regions between said patterns and preselected first active zones. Moreover, the support is formed by stacking of a substrate and of an electrically insulating thin layer, the front face of the electrically insulating thin layer forming the front face of the support.

Owner:STMICROELECTRONICS SRL +1

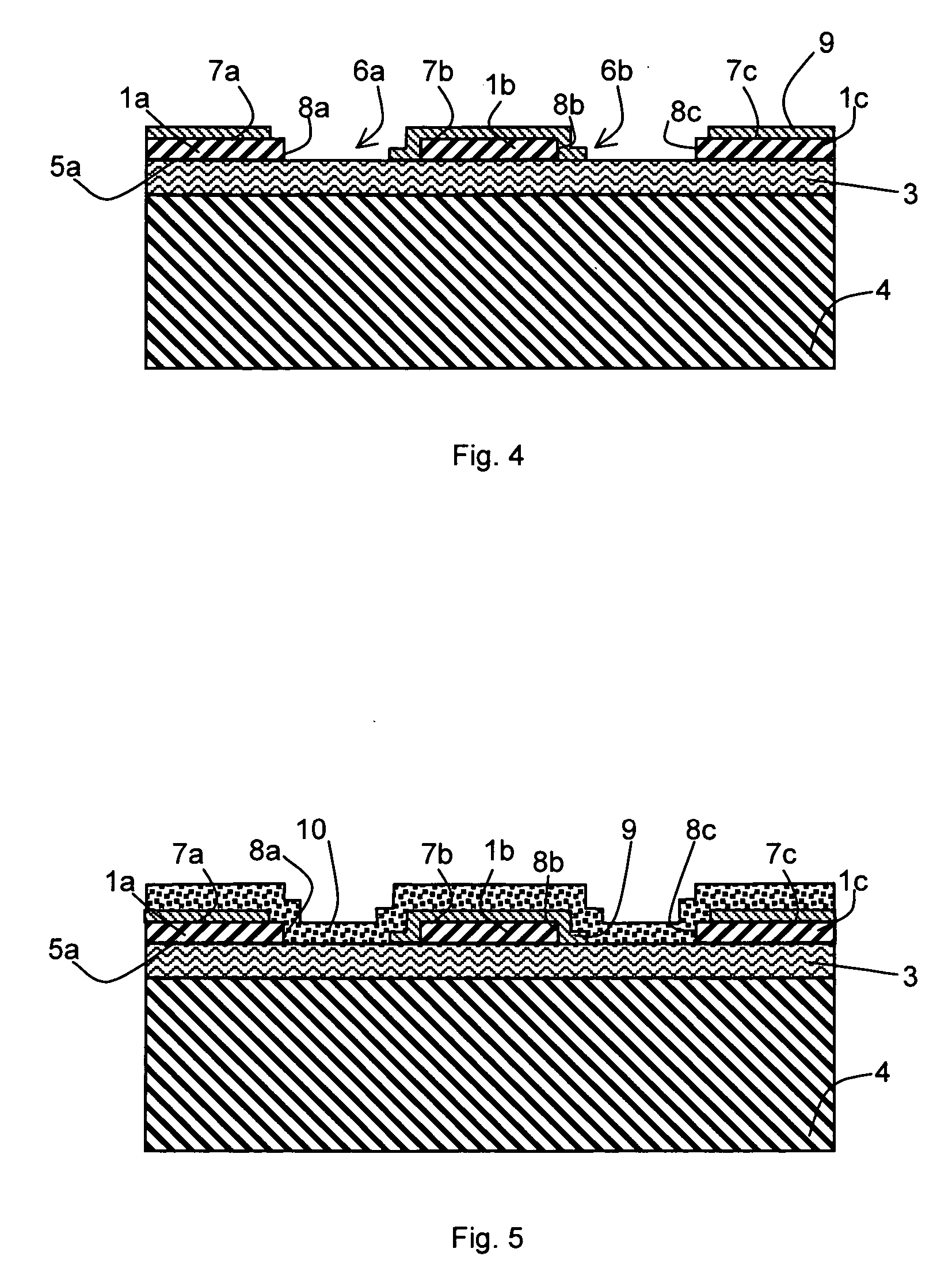

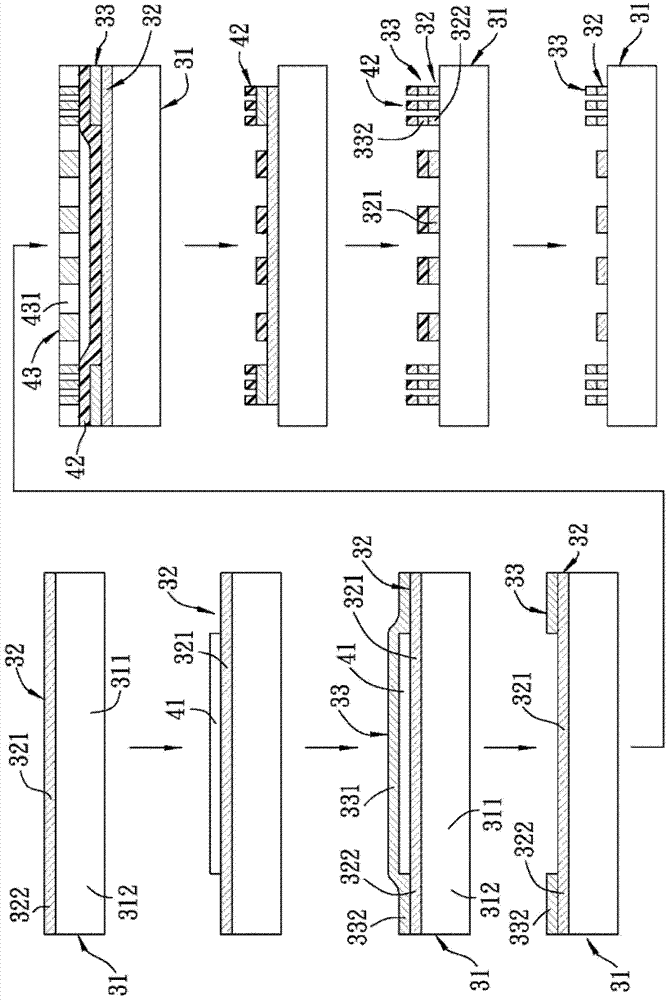

Method for making patterning conducting layer

InactiveCN103369870AThe process steps are simpleReduce processing timeConductive material chemical/electrolytical removalMultilayer circuit manufactureTectorial membraneEtching

Discloses is a method for making a patterning conducting layer, and the method comprises steps of: (A) draping a base material with a first conducting layer; (B) forming a layer of protective film on the surface of a first conducting zone of the first conducting layer; (C) draping with a second conducting layer, and the second conducting layer comprises a to-be-removed zone and a pattern-forming zone. (D) removing the protective film to expose the first conducting zone; (E) etching the pattern-forming zone of the second conducting layer and the first conducting layer to form a pattern. Before the second conducting layer is formed, the first conducting layer is shielded by the protective film at first, and then the protective film is removed so as to make the to-be-removed zone be removed together. In this way, only one time of photolithographic etching is capable of completing the making of two conducting layers, thereby simplifying processing steps and shortening processing time.

Owner:EFUN TECH CO LTD

Method for manufacturing a field effect transistor with auto-aligned grids

ActiveUS20080220569A1Semiconductor/solid-state device manufacturingSemiconductor devicesEtchingComputational physics

The method comprises steps consisting of:forming, on an isolating face of a first substrate, a stack comprising successively at least one layer of rear grid material, an electrically insulating rear grid layer, a semi-conducting zone, an electrically insulating layer for the front grid, at least one layer of front grid material and a masking element, placed facing the semi-conducting zone,forming in the layer of front grid material a pattern reproducing the shape of the masking element and comprising etching of the layer of front grid material to eliminate the front grid material outside said pattern,forming on the free faces of the pattern a sacrificial spacer covering a first part of the semi-conducting zone revealed by eliminating the grid material,forming a protective layer over the remaining part, or second part, of the semi-conducting zone revealed by eliminating the grid material,eliminating the sacrificial spacer covering said first part of the semi-conducting zone,etching the first part of the semi-conducting zone revealed in the preceding step to delineate the channel of the transistor.

Owner:COMMISSARIAT A LENERGIE ATOMIQUE ET AUX ENERGIES ALTERNATIVES

Radiation detector element and imager comprising an assembly of radiation detector elements

Disclosed is a radiation detector element including a stack of layers superimposed in a stacking direction, the stack having a first face and a second face and including a radiation-absorbing layer consisting of a first semiconductor material having a first band gap value and at least one barrier layer consisting of a second semiconductor material having a second band gap value, the second band gap value being strictly greater than the first band gap value. The stack further delimits a primary hole traversing each of the layers of the stack, the primary hole receiving at least part of a primary electrode. The barrier layer includes a first conducting zone having a free carrier density greater than or equal to 1.1017 / cm−3.

Owner:THALES SA +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com