Scanning method for material increase manufacturing three-dimensional body

A technology of three-dimensional objects and scanning methods, which is applied in the field of additive manufacturing, can solve the problems of low efficiency during scanning and processing of three-dimensional objects, and achieve the effects of improving scanning processing efficiency, ensuring processing accuracy, and balancing processing accuracy and processing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

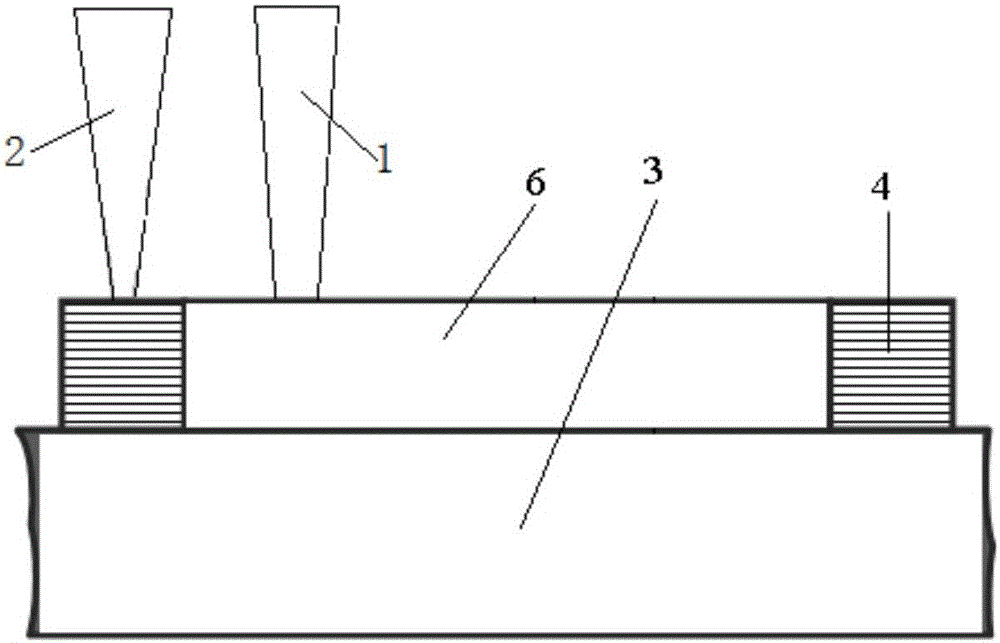

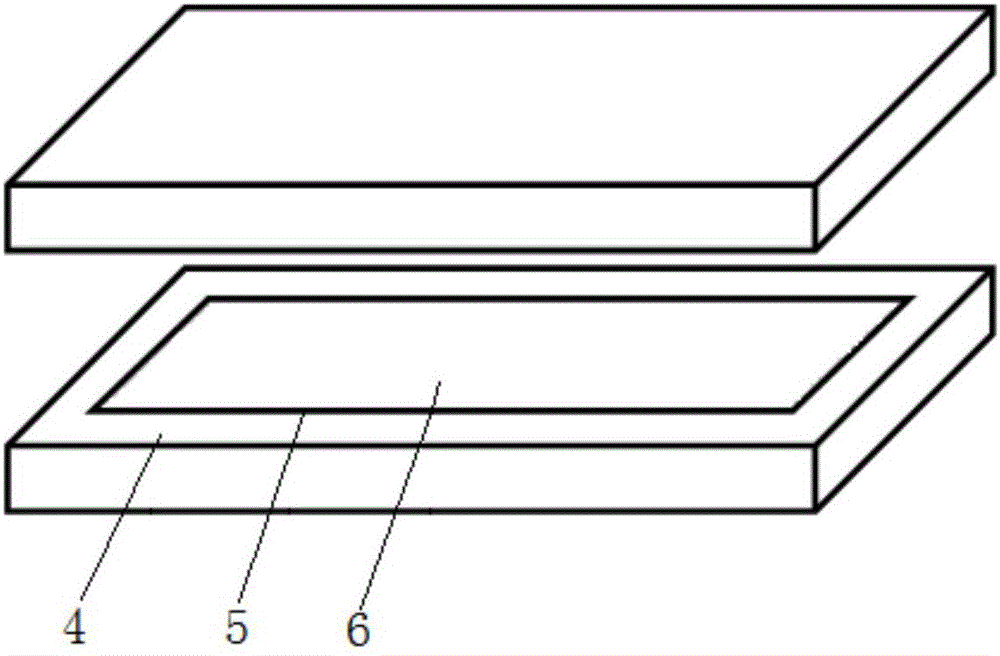

[0030] Further, on the premise of ensuring the processing accuracy of the three-dimensional object 3, in order to further improve the processing efficiency of the three-dimensional object 3, when scanning a slice containing both the surface area 4 and the internal area 6, the small spot heat source 2 follows the scanning path, every After scanning the surface area 4 of the c-layer slice, the large-spot heat source 1 conducts an overall scan of the inner area 6 of the c-layer slice, where c is the multi-layer single-firing coefficient of the inner area 6, and c is an integer. Its specific implementation steps are as follows:

[0031] Step 1: Input the m-layer slice file of the 3D object 3 model, and the surface area 4 threshold L 1 , multi-layer single-firing coefficient c in the inner area 6, the total height H of the three-dimensional object 3 along the Z-axis direction, the thickness of the single-layer slice Δh, the i-th slice is the current slice, where, 1≤i≤m, Indicates...

Embodiment 2

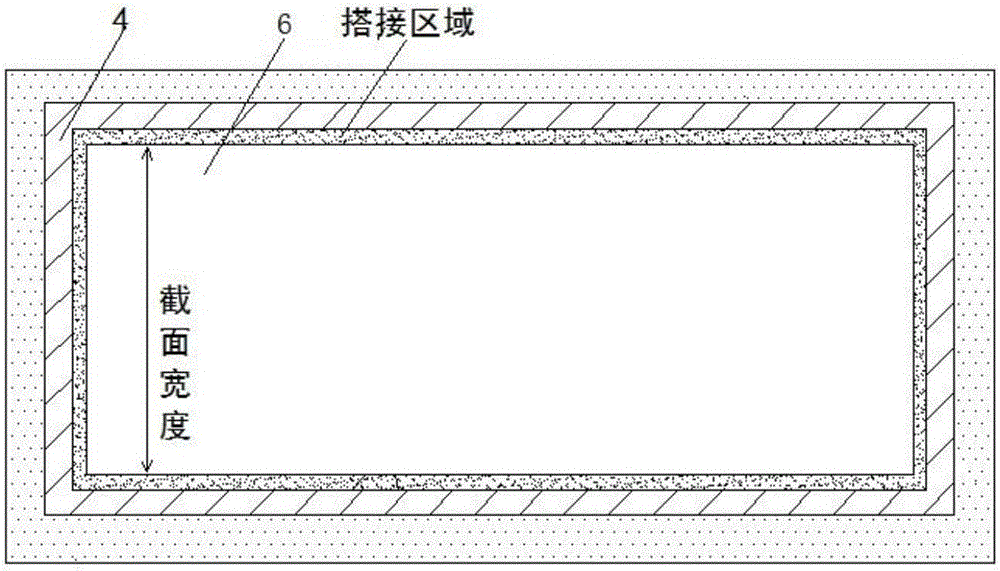

[0039] In order to further improve the processing efficiency of the three-dimensional object 3, after the division of the surface area 4 and the internal area 6 of the single-layer slice of the three-dimensional object 3 is completed, if the cross-sectional width of the profile of the internal area 6 in the X and / or Y directions is less than twice the overlap When the width is wide, the area within the cross-section of the three-dimensional object 6 in the X and / or Y direction whose cross-sectional width is less than twice the overlap width is scanned with a small-spot heat source 2, and the rest of the internal area 6 is scanned with a large-spot heat source 1 scanning. The specific implementation steps are as follows:

[0040] Step 1: Input the m-layer slice file of the 3D object 3 model, and the surface area 4 threshold L 1 , multi-layer single-firing coefficient c in the inner area 6, the total height H of the three-dimensional object 3 along the Z-axis direction, the thi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com