Three-dimensional zoned collaborative caving mining method for pillar groups

A technology of caving mining and pillars, which is applied in the field of collaborative caving mining with three-dimensional partitioning of pillar groups in the environment of large empty areas, which can solve problems such as potential safety hazards of pillar mining in empty areas, pillar damage, and loss of pillar resources, etc., to avoid High output rate of large blocks, poor effect of avoiding blasting, and simplified operation procedures

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

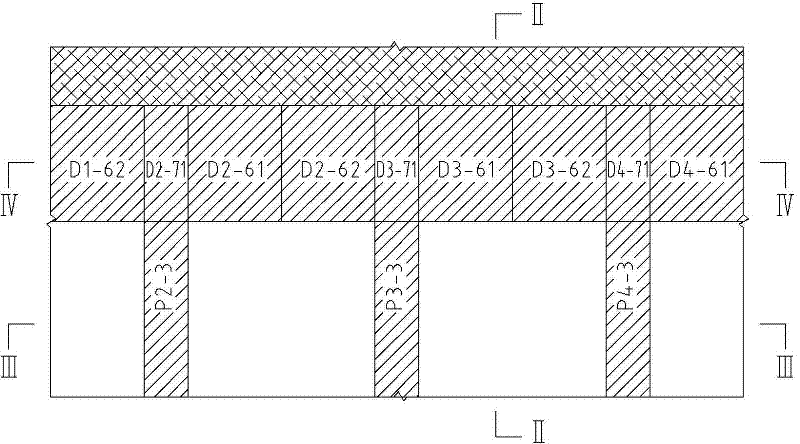

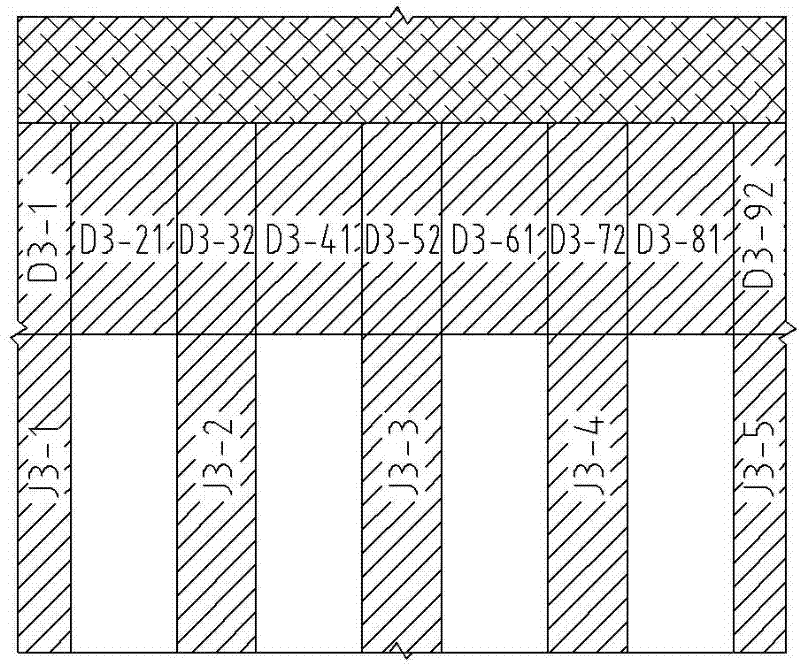

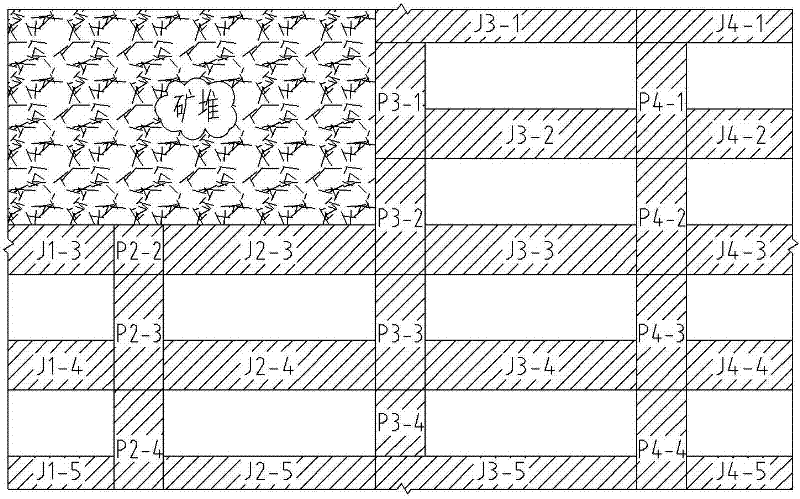

Embodiment approach 1

[0011] The mining object of embodiment one is the ore pillar group of ore inter-pillar and ore top pillar under the condition of large empty area, see Figure 1-Figure 4 , The inter-columns include room columns and disc inter-columns, the inter-columns are 30m-100m long, 15m-25m wide, and 40m-60m high. The key point of pillar group mining is to ensure safe production and achieve high efficiency and low cost in the process of pillar mining. Connect room columns J2-3, J2-4, J3-2, J3-3, J3-4 with disc columns P3-1, P3-2, P3-3, P3-4 and top columns D2-5, D2- 6. D2-7, D2-8, D3-2, D3-3, D3-4, D3-5, D3-6, D3-7, D3-8, D3-9 and other pillars are divided into a caving unit. In the three-dimensional space of this caving unit, the intercolumn partitions J2-3, J2-4, J3-2, J3-3, J3-4, P3-1, P3-2, P3-3, P3-4 and Column partition D2-52, D2-61, D2-62, D2-72, D2-81, D2-82, D3-21, D3-22, D3-31, D3-32, D3-41, D3-42 , D3-51, D3-51, D3-61, D3-62, D3-71, D3-72, D3-81, D3-82, D3-91 and other 30 di...

Embodiment approach 2

[0014] Implementation mode two, see Figure 1-Figure 4 , the ore pillar group is the ore inter-column and the surrounding rock roof above the void. The inter-column includes the room column and the inter-panel column. The inter-column is 30m-100m long, 15m-25m wide, and 40m-60m high. The mining of the pillar group will involve the treatment of the empty area and the treatment of the roof of the empty area. In the mining process of the ore pillar group, it is not only necessary to ensure safe production, but also to minimize the mixing of roof surrounding rocks, avoid excessive ore dilution and loss rates, and achieve high efficiency and low cost. Connect room columns J2-3, J2-4, J3-2, J3-3, J3-4, inter-panel columns P3-1, P3-2, P3-3, P3-4 and top plates D2-5, D2-6 , D2-7, D2-8, D3-2, D3-3, D3-4, D3-5, D3-6, D3-7, D3-8, D3-9 are divided into a caving unit. For the mining of this caving unit, the intercolumn partitions J2-3, J2-4, J3-2, J3-3, J3-4, P3-1, P3-2, P3-3, P3- 4 and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com