Repairing method for split sealing surface of pressure resistant vessel

A technology for a pressure vessel and a repair method, applied in the field of pressure vessels, can solve the problem of few repair technologies, and achieve the effects of stable and reliable sealing effect, short cycle and strong practicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

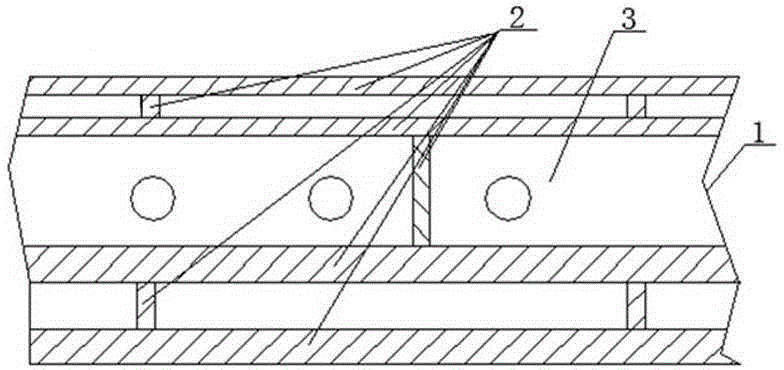

[0025] The pressure vessel of the present invention is preferably a steam turbine cylinder, which is mainly composed of an upper half cylinder body and a lower half cylinder body in a manner that cooperates with the sky and the ground. High-strength fastening bolts, the upper half cylinder and the lower half cylinder are sealed together by the fastening bolts, and the corresponding sealing surfaces of the upper half cylinder and the lower half cylinder are formed horizontally to form the upper half cylinder and the lower half cylinder. The split sealing surface between the cylinder halves. Since the cylinder of the present invention has a large structural volume and needs to carry high-temperature and high-pressure steam, deformation will occur at the middle sealing surface between the upper half cylinder and the lower half cylinder of the cylinder under long-term service. , resulting in a deformation gap, causing the medium-steam leakage in the cylinder.

[0026] To this phe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com