Polishing disk surface finishing device

A dressing device and polishing disc technology, applied in abrasive surface adjustment devices, grinding devices, grinding/polishing equipment, etc., can solve the problems of easy deformation, inability to process wafers, affecting geometric parameters, etc., and achieve the effect of repairing deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention will be further described below in conjunction with the accompanying drawings.

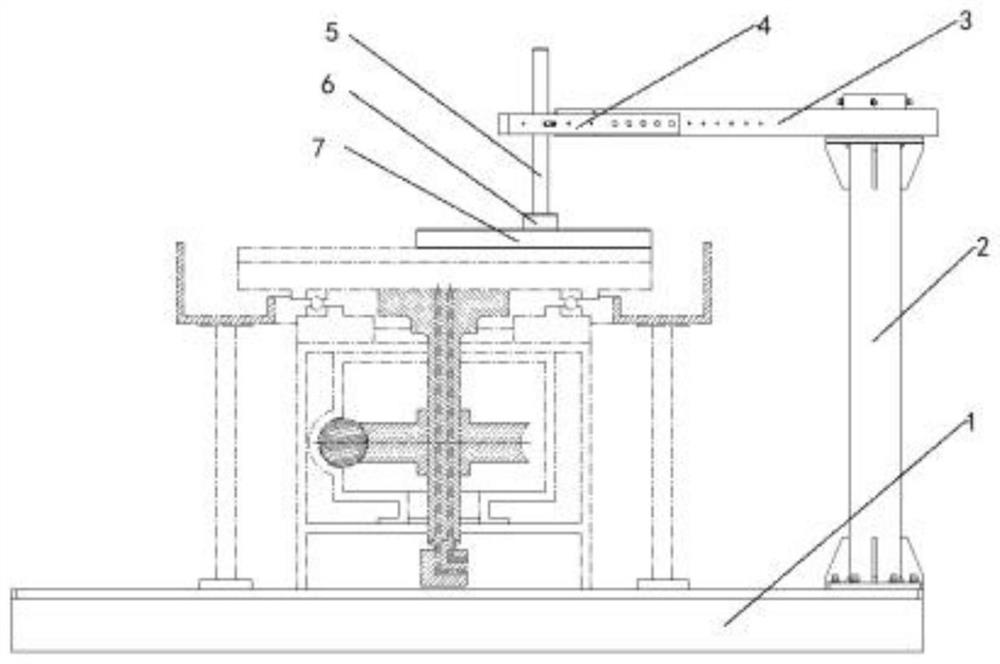

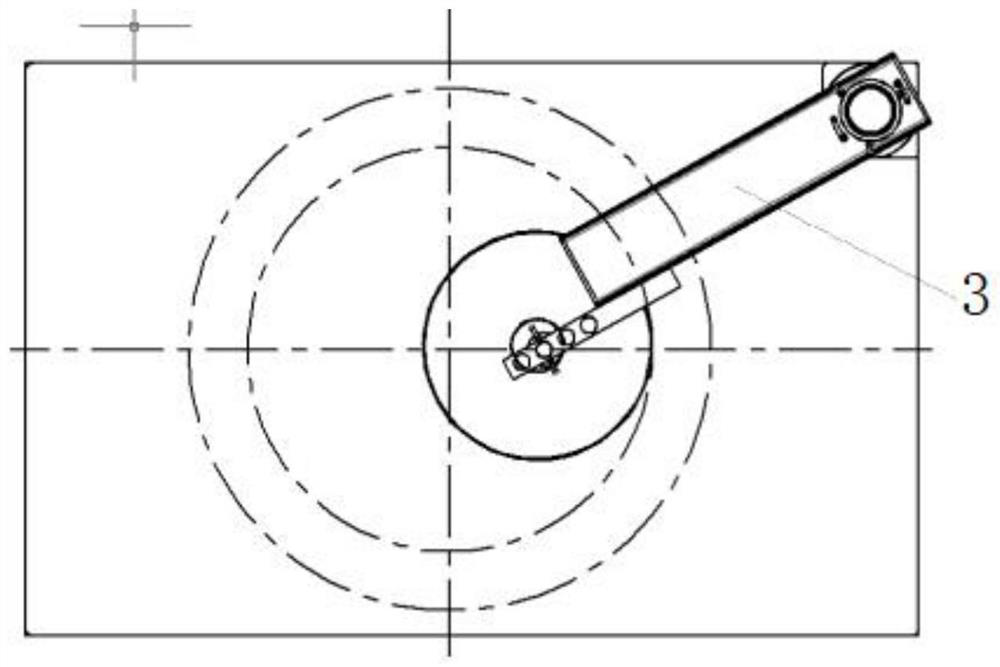

[0033] like figure 1 , 2 As shown, a polishing disc surface conditioning device, comprising: image 3 Platform 1 shown, such as Figure 4 Column 2 shown, such as Figure 5 Beam 3 shown, such as Image 6 As shown in the positioning rod 4, such as Figure 7 The guide rod 5, guide wheel 6 and as shown Figure 8 Grinding disc 7 shown.

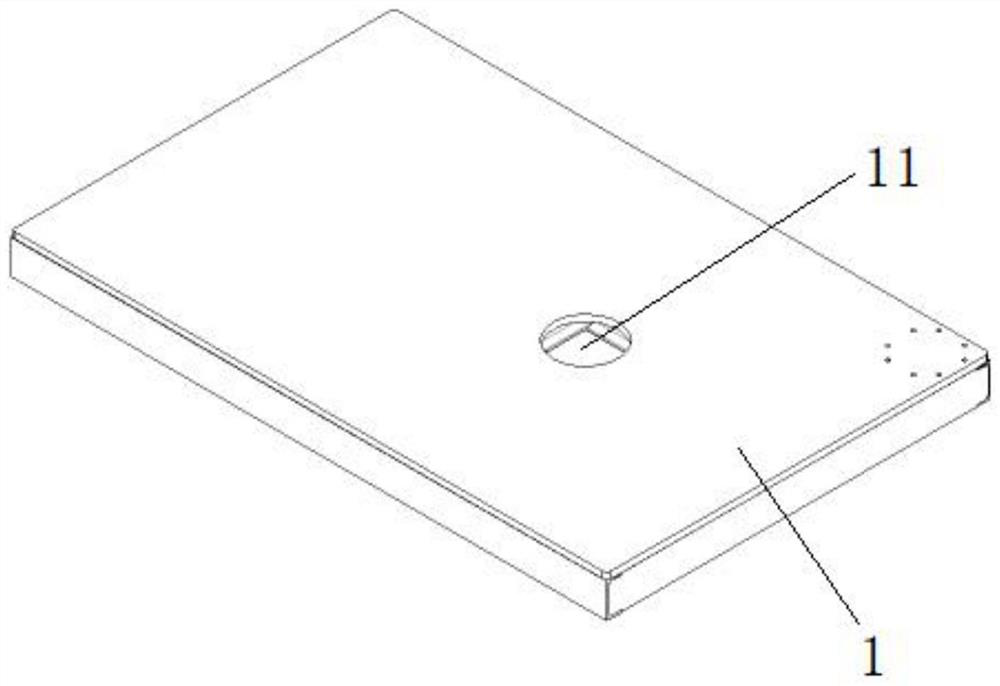

[0034] A rotatable polishing disc can be placed on the platform 1 . The platform is welded with medium-thickness steel plate and channel steel. Reserve in the middle of the platform The through hole 11 is convenient to pass constant temperature cooling water when grinding and polishing the disc.

[0035] The bottom end of the upright column 2 is fixed on the platform 1 by screws. The top of the column 2 is sleeved with a flange 21 , a plurality of triangular reinforcing ribs 22 are arranged between the bottom surface of the flan...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com