Correcting method and corrector of water jacket aperture of molten steel continuous casting crystallizer

A technology of continuous casting crystallizers and crystallizers, which is applied in the field of machinery manufacturing equipment, can solve the problems of waste materials and delays in work, and achieve the effect of saving the cutting and sawing process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] Below in conjunction with accompanying drawing and specific embodiment the function of the present invention is described in further detail:

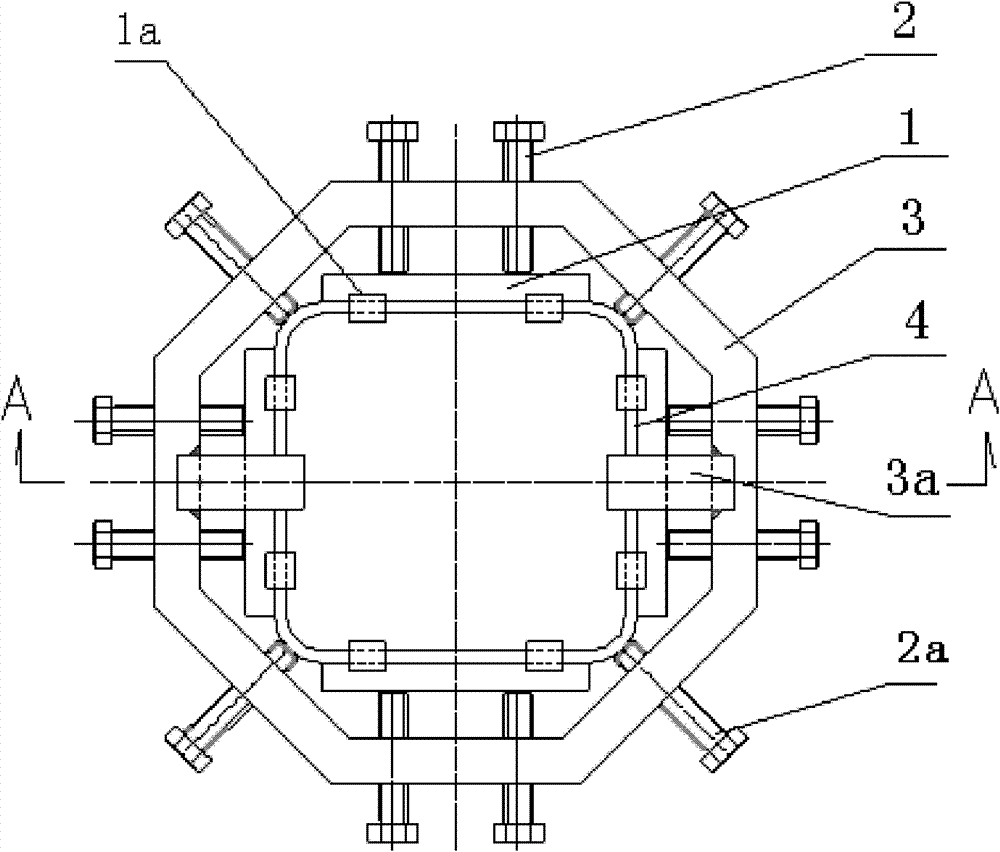

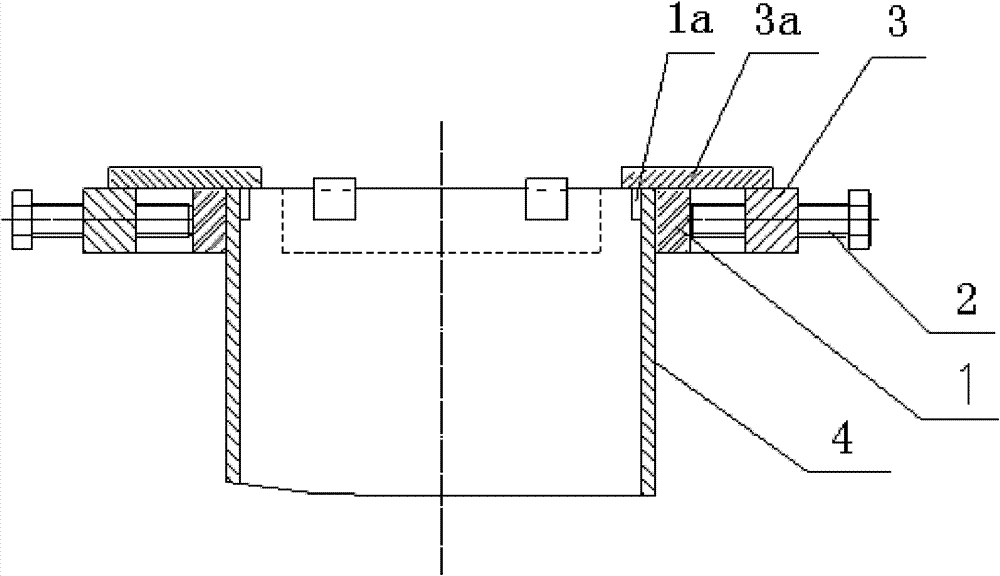

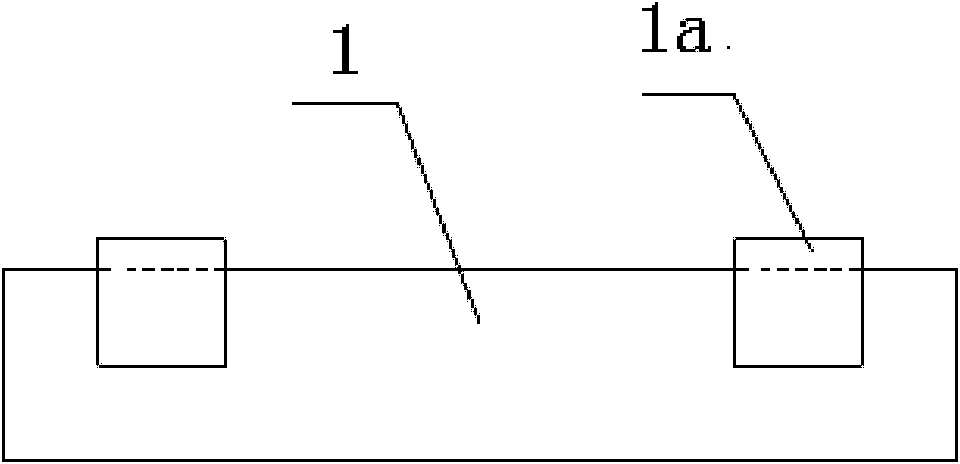

[0028] Such as figure 1 , figure 2 : Molten steel continuous casting crystallizer water jacket face corrector of the present invention comprises pressing plate part and correcting part, and pressing plate part comprises belt hook pressing plate 1, and band hook pressing plate 1 totally four pieces, and band hook pressing plate 1 top is to be with the crystallizer water to be corrected. The hook 1a matched with the surrounding wall of the socket 4, the correcting part includes a regular octagonal correcting frame 3 set on the outside of the hook plate 1, the upper end of the correcting frame 3 corresponds to two sides with horizontal steel bars that can be placed on the port of the crystallizer water jacket 3a, one or two internal screw holes and matching compression bolts 2 are evenly arranged on each side of the four sides par...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com