Variable diameter drill and mill for oil and gas wells

An oil and gas well, drilling and milling technology, which is applied in the field of variable diameter drilling and milling machines for oil and gas wells, can solve problems such as the inability of the drill bit to accurately find the target wellbore, the high downhole safety risk, the downhole accident and the accident, etc., so as to achieve safe downhole engineering goals, The effect of reducing downhole complications and accidents and increasing success rates

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described below in conjunction with embodiment and accompanying drawing.

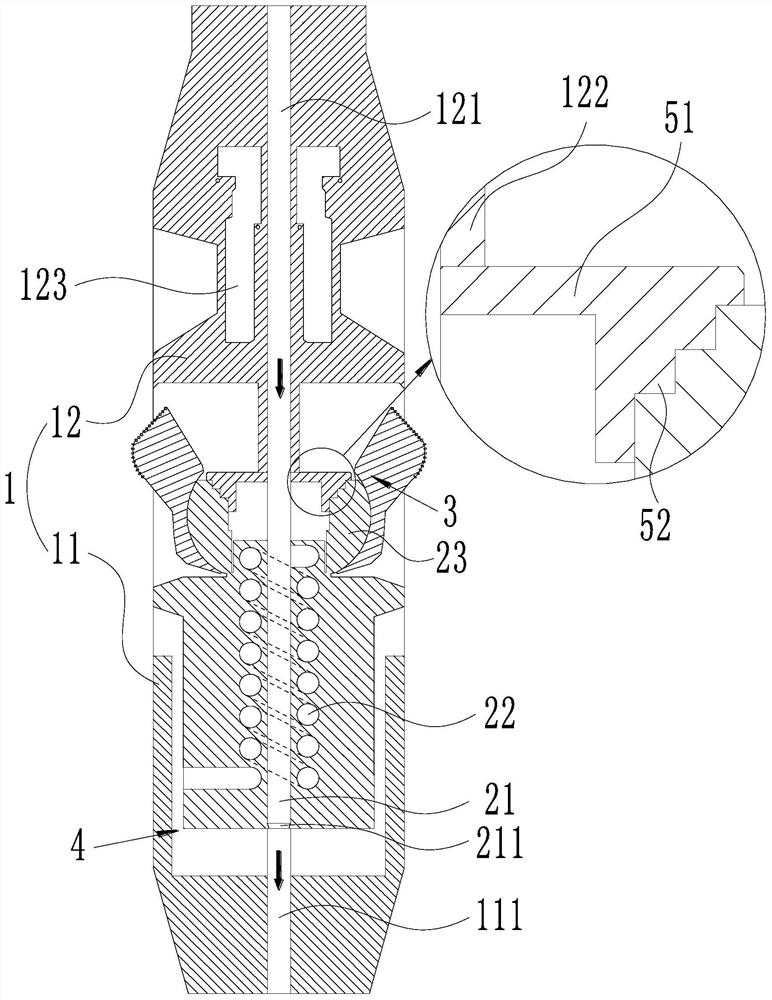

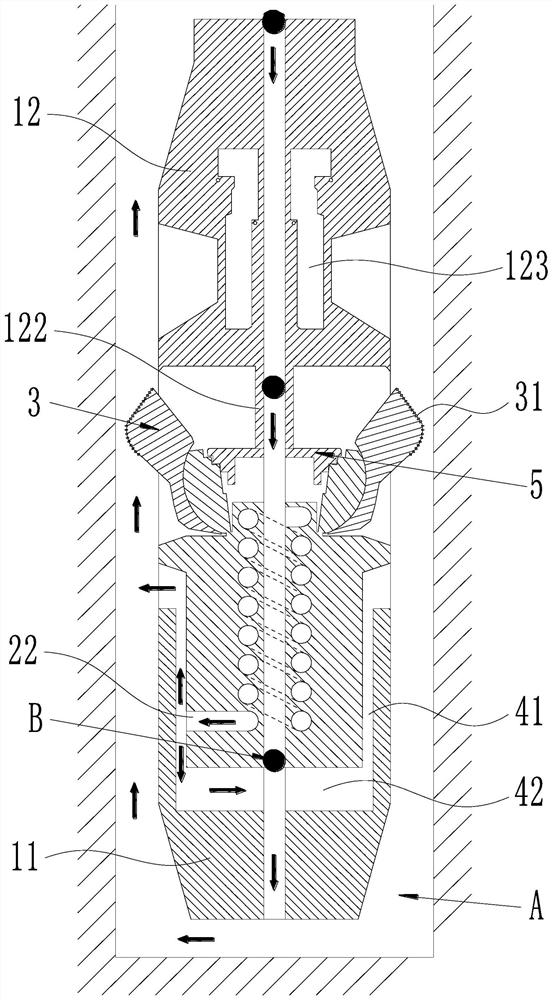

[0023] Such as figure 1 and figure 2 As shown, a variable-diameter drilling and milling device for oil and gas wells mainly includes a drilling and milling device main body 1 composed of a lower mounting cylinder 11 and an upper driving cylinder 12, both of which have a cylindrical structure. Therefore, the drill-mill main body 1 also has a cylindrical structure. Moreover, the upper drive cylinder 12 is arranged on the top of the lower installation cylinder 11, and can move up and down along the lower installation cylinder 11. A diameter-changing mechanism installation cavity is formed between the lower installation cylinder 11 and the upper drive cylinder 12. There is a variable diameter drilling and milling mechanism. The variable diameter drilling and milling mechanism includes a core body 2 installed on the lower installation cylinder 11 and a number o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com