Roof water draining method based on directional drilling technique

A technology of directional drilling and directional drilling, which is applied in directional drilling, drainage, earth-moving drilling, etc., can solve the problems of affecting the drainage efficiency, drilling waste, waste of coal resources, etc., so as to improve the utilization rate of drilling and drilling. The effect of hole construction efficiency, shortening drilling workload, and improving water drainage efficiency

Active Publication Date: 2017-01-04

SHAANXI COAL & CHEM TECH INST

View PDF5 Cites 7 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0004] (1) The pumping (draining) water test used in the exploration of the water-richness of the roof is calculated from the geological information on the "point" of the drilled hole, and the water-richness of the surrounding area cannot be inferred from "points and planes", and it takes a long time and The cost is high; although geophysical exploration can detect the water-richness on the "surface" (area), there are multiple solutions to explain and delineate the water-richness, and the reliability is poor

[0005] (2) The geological information used in risk assessment of roof inrush (outburst) generally cannot fully reflect the geological and mining conditions of specific coal mines, and the geologi

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Login to View More

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| Caliber | aaaaa | aaaaa |

Login to View More

Abstract

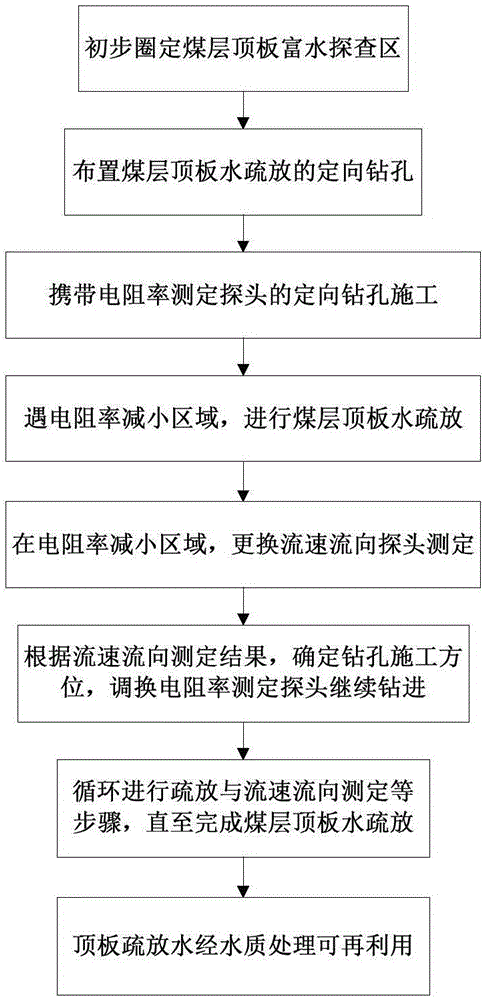

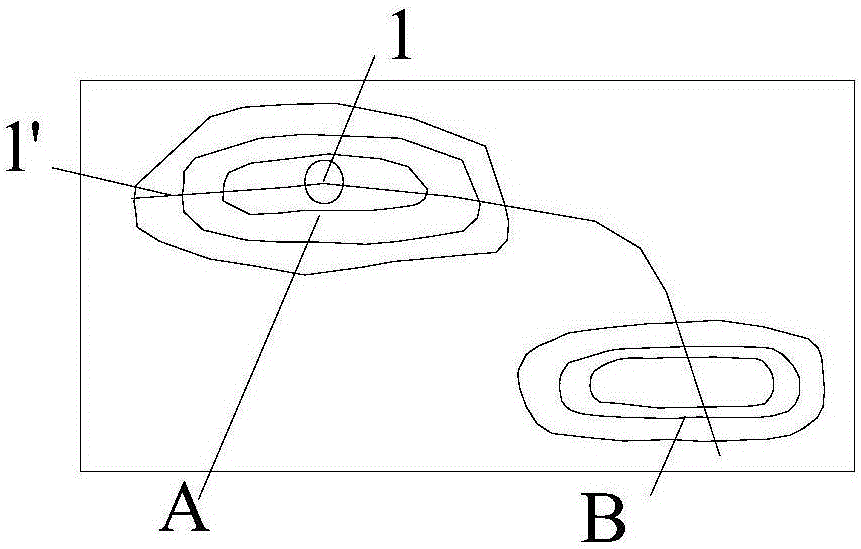

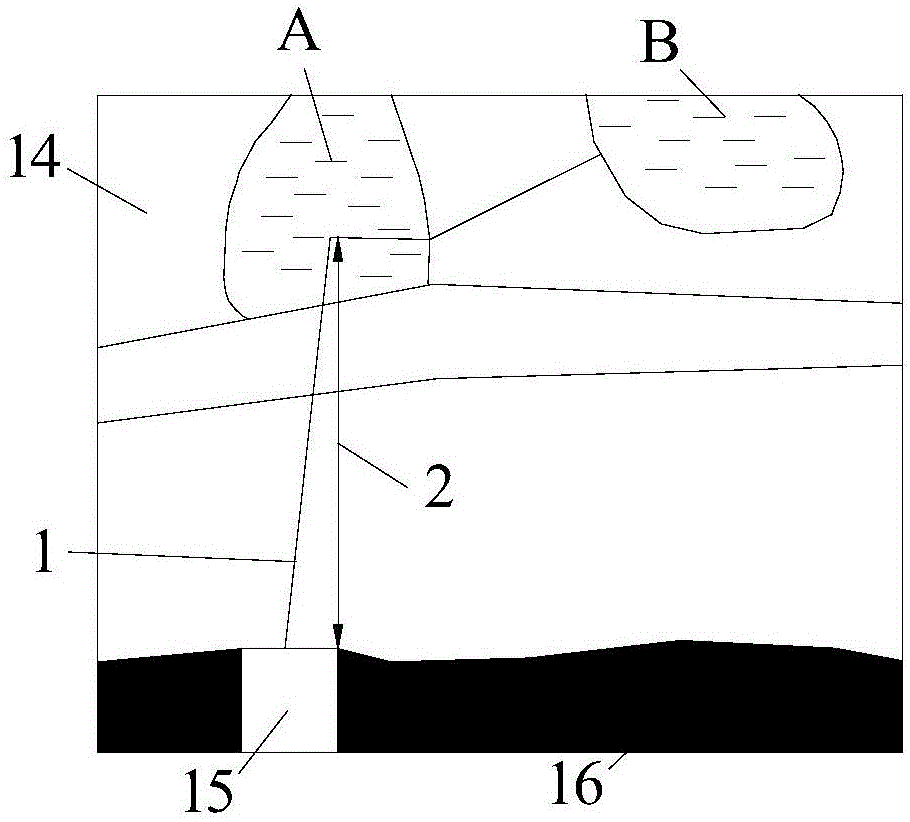

A roof water draining method based on a directional drilling technique comprises the steps that (1) according to the specific field of drilled holes, a water-rich detection area of a roof of a coal seam is determined; (2) according to the largest development height of a water conducted zone after the coal seam is mined as well as the water-rich detection area, determined in the step (1), of the roof of the coal seam, a target area of directional drilling in the space is determined, and a coal seam roof water draining directional drilled hole (1) is formed in the target area; (3) directional drilling is conducted through a resistivity measuring probe, in the directional drilling process, if the resistivity is reduced, water draining measures are taken, and if the resistivity does not change obviously, measurement is continued; (4) the flow speed and flow direction of underground water of the water-rich area are measured with the roof water draining area in the step (3) as the initial point; (5) according to the flow speed and flow direction, measured in the step (4), of the underground water of the water-rich area, the directional drilling direction is adjusted, and directional drilling is continued; and (6) the steps (3)-(5) are repeatedly conducted, and roof water draining of a whole recovery area is completed.

Description

【Technical field】 [0001] The invention belongs to the field of coal mining, and in particular relates to a roof water dredging method based on directional drilling technology. 【Background technique】 [0002] my country's coal resources are very rich, but the hydrogeological conditions of the coal seam roof in most areas have not been fully investigated, especially the water richness of the roof is difficult to accurately grasp, which leads to the occurrence of roof water damage accidents during the coal seam recovery stage. On the one hand, it brings serious economic losses to coal mines. Damage to underground equipment and increase drainage costs, on the other hand, cause the loss of groundwater resources and aggravate the water shortage in water-scarce mining areas. At the same time, water damage accidents threaten the lives of miners. Therefore, before the recovery of coal resources, it is important to detect the water-richness of the roof of the coal seam as accurately as...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): E21F16/00E21B7/04

CPCE21B7/04E21F16/00

Inventor 冯洁王苏健陈通段会军李涛薛卫峰

Owner SHAANXI COAL & CHEM TECH INST

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com