Method for distinguishing ultra-close coal seam/group

A discrimination method and extremely short-distance technology, applied in the field of discrimination, can solve the problems of no unified determination standard

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] Below in conjunction with certain ore 12,14 coal seams and 16,17 coal seams are specific embodiments the present invention is described in detail, but the present invention is not limited to following example:

[0030] Calculation method of the present invention comprises the following steps:

[0031] (1) According to the actual survey of the mine, the geological data of the relevant coal seams are obtained, including the thickness of the coal seam (mining), the lithology characteristics of the roof and the vertical distance between the coal seams;

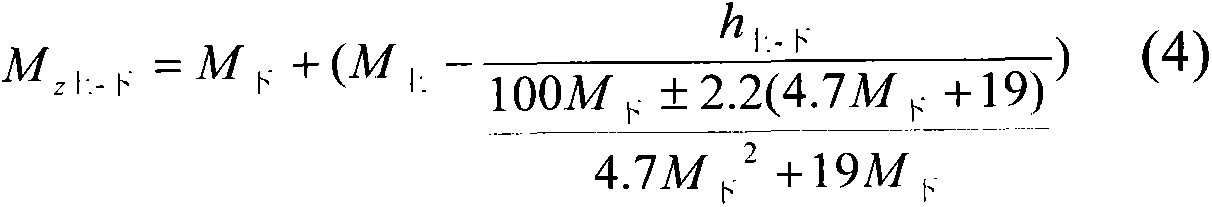

[0032] According to the data, the maximum mining thickness of 12, 14, 16 and 17 coal seams are respectively M 12 =2.1m, M 14 = 1.3m, M 16 = 1.2m, M 17 = 1.7m, the roof lithology of each coal seam is moderately hard, and the vertical distance between coal seams 12 and 14 is h 12-14 =1.8m, the vertical distance between 16 and 17 coal seams h 16-17 =2.4m;

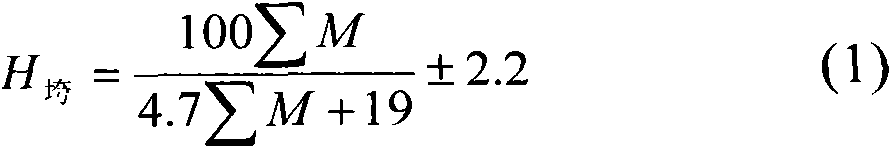

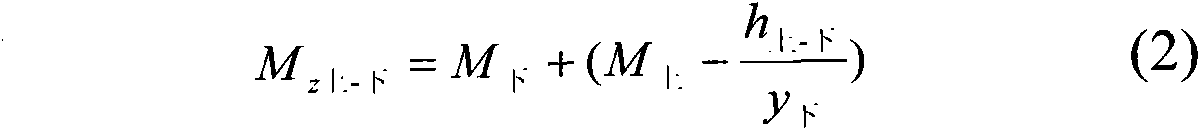

[0033] (2) According to the relevant coal seam parameters obtain...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com