Method for single metal droplet supercooling degree measurement by large cooling speed in situ fast thermal analysis

A thermal analysis, subcooling technology, applied in the investigation phase/state change and other directions, can solve problems such as inability to test subcooling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] In this embodiment, Sn-3.0Ag-0.5Cu (wt.%), a typical lead-free solder alloy, is selected as the single metal droplet material.

[0020] The concrete processing steps of the present embodiment are as follows:

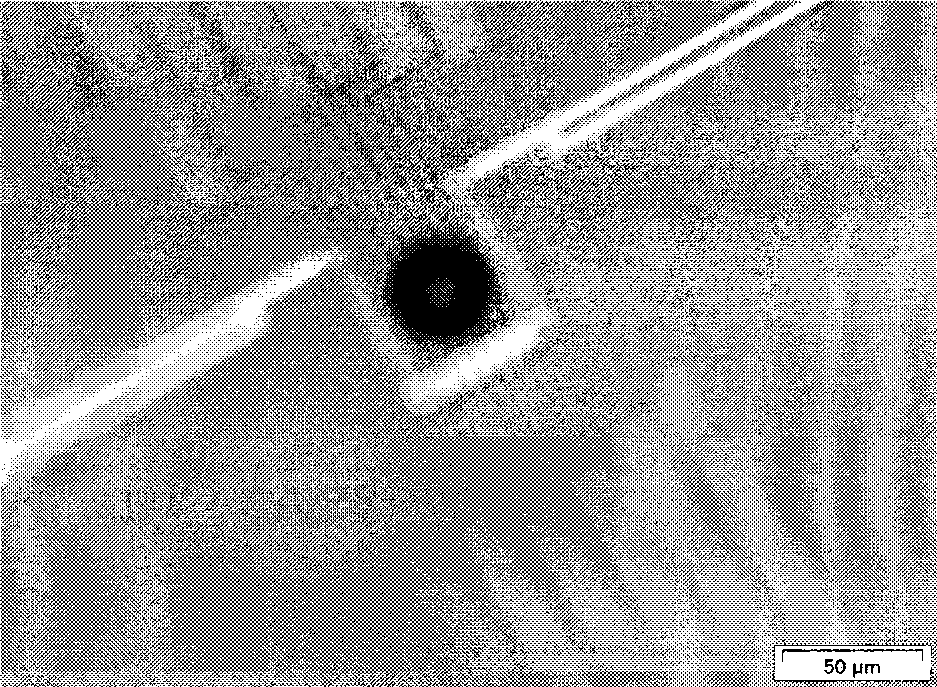

[0021] (1) Select the required single metal solidification droplet under the optical microscope, and place it in the heating area of the sensor of the rapid thermal analysis device;

[0022] (2) After the droplet is positioned, use an optical microscope for magnified observation to ensure that the position of the droplet is precisely controlled, located above the center of the sensor heating area, and determine the size of a single droplet, which is 47 μm in size, see appendix figure 1;

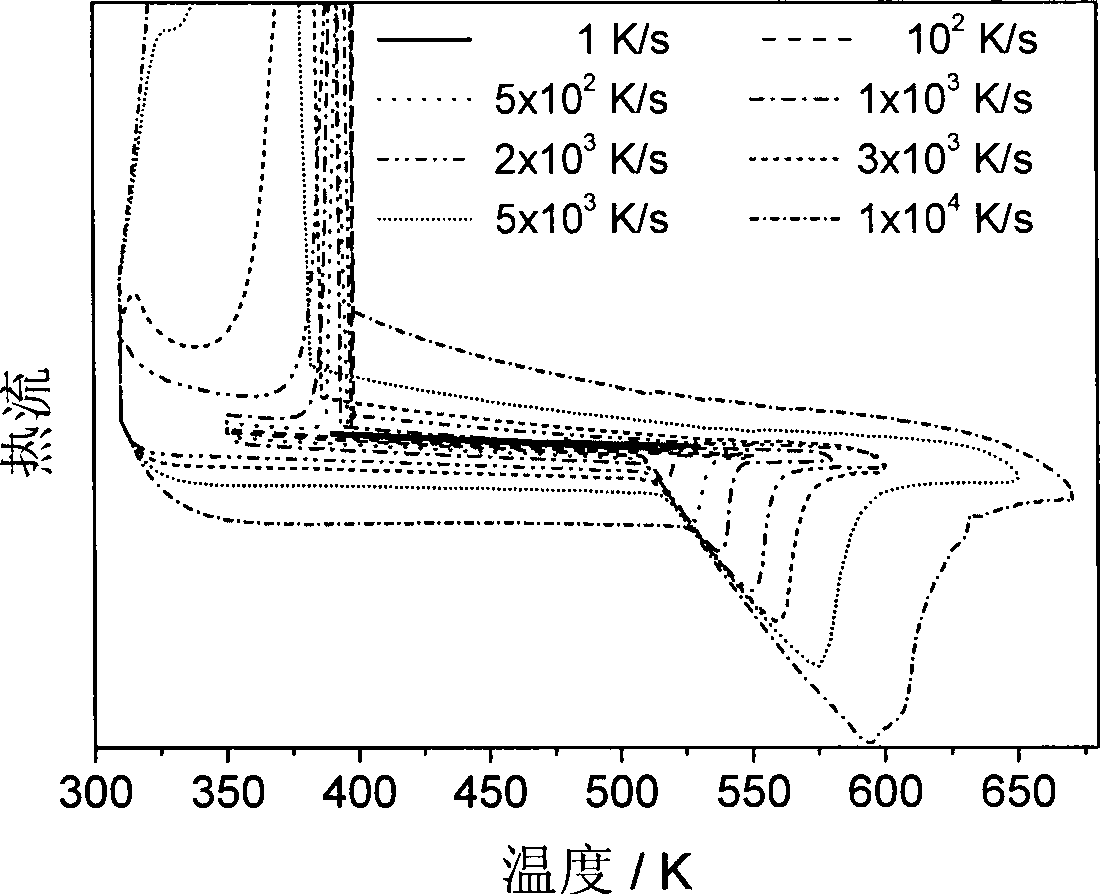

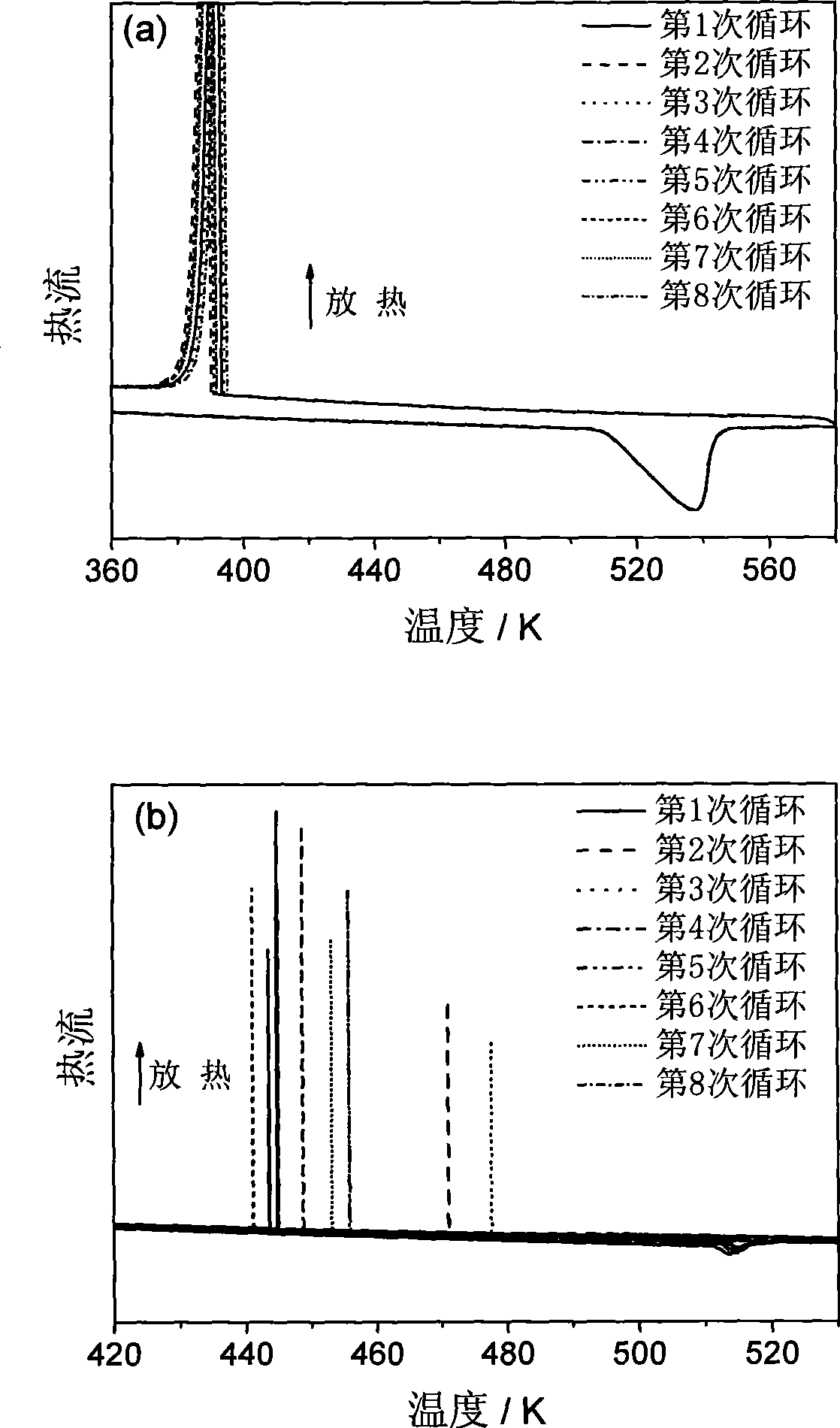

[0023] (3) Use rapid thermal analysis equipment to measure the heating and cooling curves of the above-mentioned single metal droplet in real time, and the heating and cooling rates are respectively selected as 1, 1×10 2 , 5×10 2 , 1×10 3 , 2×10 3 , 3×10 3 , 5×10 3 and ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com