A method and device for measuring the subcooling degree of rapid solidification of metal droplets

A technology of subcooling and metal particles, which is applied in the investigation stage/state change, etc., can solve the problems of inability to test the subcooling degree and the low cooling rate of the metal melt, so as to avoid heterogeneous nucleation, strong repeatability, Thermal history consistent effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

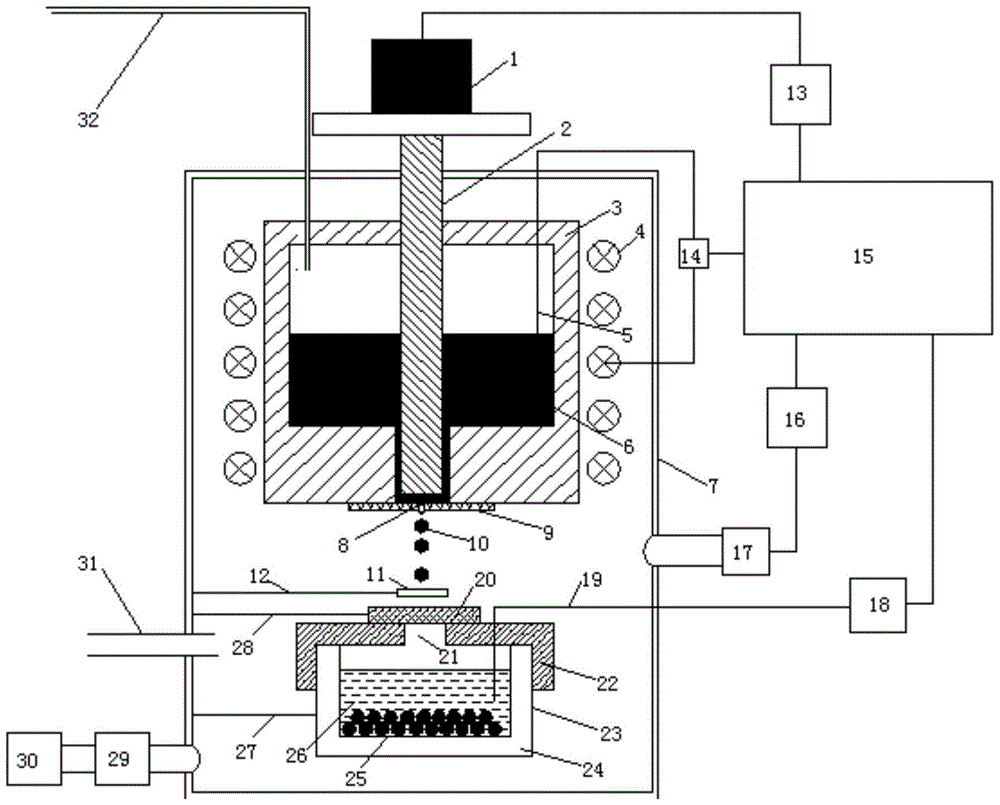

[0038] Such as figure 1 The device used in the method for measuring the subcooling degree of rapid solidification of metal droplets shown includes a vacuum system, a droplet ejection system, an image acquisition system and a droplet temperature testing system, and the droplet temperature testing system is installed Inside the vacuum system, the droplet injection system is installed directly above the droplet temperature testing system, and the image acquisition system is connected to the vacuum chamber of the vacuum system.

[0039] The vacuum system includes a vacuum chamber 7, a mechanical pump 30 and a diffusion pump 29. The diffusion pump is installed on the side wall of the vacuum chamber, the mechanical pump is connected to the diffusion pump, and the vacuum chamber is also equipped with a cavity intake pipe 31 and The crucible inlet pipe 32, before vacuuming, closes the cavity inlet pipe and the crucible inlet pipe through a valve, and the vacuum degree in the vacuum ch...

Embodiment 2

[0081] Embodiment 2 is identical with device and assay method in embodiment 1, and the different related parameters of this device and method are as follows:

[0082] (1) The aperture of the small hole 8 in the device is 0.150 mm, and the vibration frequency of the piezoelectric ceramic is 700 Hz;

[0083] (2) Step 1, in the preparation of metal microparticle droplets by the pulse micropore method (2) vacuuming: use the mechanical pump 30 and the diffusion pump 29 to vacuumize the crucible 3 and the vacuum chamber 7 to a vacuum degree of 0.0009Pa;

[0084] (3) Step 1, in the preparation of metal microparticle droplets by pulse microporous method (3) molten metal: after the metal material is completely melted, keep it warm for 20 minutes;

[0085] (4) Step 1, the pulse microporous method in the preparation of metal microparticle droplets (4) pulse jetting: pass inert gas into the crucible 3 through the crucible inlet pipe 32, so that a stable differential pressure is reached be...

Embodiment 3

[0087] Embodiment 3 is identical with device and measuring method in embodiment 1, and the different related parameters of this device and method are as follows:

[0088] (1) The diameter of the small hole in the device is 1.500 mm, and the vibration frequency of the piezoelectric ceramic is 1 Hz;

[0089] (2) Step 1, in the preparation of metal microparticle droplets by the pulse microporous method (2) vacuuming: use the mechanical pump 30 and the diffusion pump 29 to vacuumize the crucible 3 and the vacuum chamber 7 to a vacuum degree of 0.0007Pa;

[0090] (3) Step 1, in the preparation of metal microparticle droplets by pulse micropore method (3) molten metal: after the metal material is completely melted, it is kept for 30 minutes;

[0091] (4) Step 1, the pulse microporous method in the preparation of metal microparticle droplets (4) pulse jetting: pass inert gas into the crucible 3 through the crucible inlet pipe 32, so that a stable differential pressure is reached betw...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| Resonant frequency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com