A method and device for preparing ultrafine spherical metal powder for 3D printing

A metal powder and 3D printing technology, which is applied in the field of spherical particle preparation, can solve problems such as poor sphericity, poor spreadability and fluidity, and achieve the effects of high sphericity, consistent thermal history, and increased production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

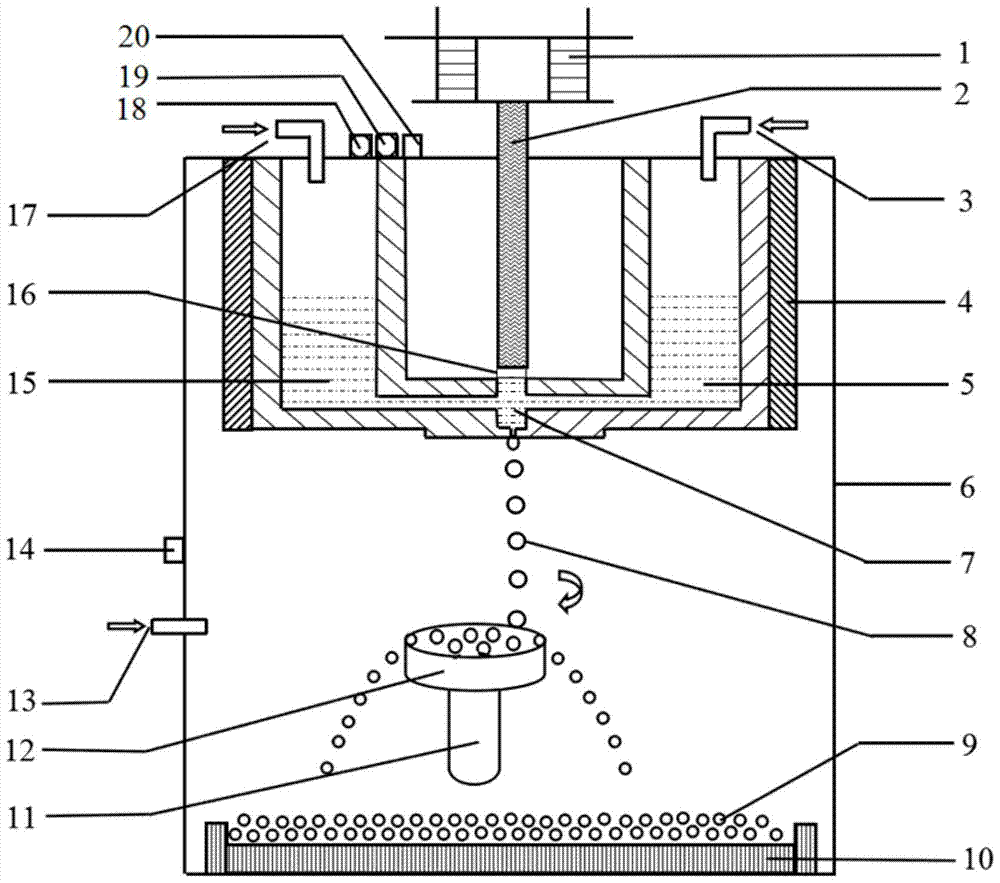

[0048] Specific implementation of batch preparation of Sn-3Ag-0.5Cu spherical powder for 3D printing:

[0049] The Sn-3Ag-0.5Cu raw material is broken into small pieces, put into the left molten pool 15 and the right molten pool 5 after ultrasonic vibration, and the central hole diameter of the crucible is selected according to the needs, and the diameter of the central hole is in the range of 0.02mm-2.0 Between mm, such as preparing 25μm-50μm particles, choose a center hole of 0.02mm-1.0mm, such as preparing 50μm-100μm particles, choose a center hole of 1.0mm-2.0mm; the amount of Sn-3Ag-0.5Cu raw material put in reaches 50%-70% of the volume of the left molten pool 15 and the right molten pool 5, such as figure 1 shown;

[0050] Use the mechanical pump 18 to pump the shell 6 and the crucible 7 to a low vacuum of 5Pa or less, and then use the diffusion pump 19 to pump the shell 6 and the crucible 7 to a high vacuum of 0.001Pa; use the first crucible air inlet pipe 3 and the s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com