Quadric injection metal atomization device of rotary-forming film

A secondary injection and atomization device technology, applied in the field of metal atomization devices, can solve problems such as the gap in the yield of fine metal powder, and achieve the effect of refining grains

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

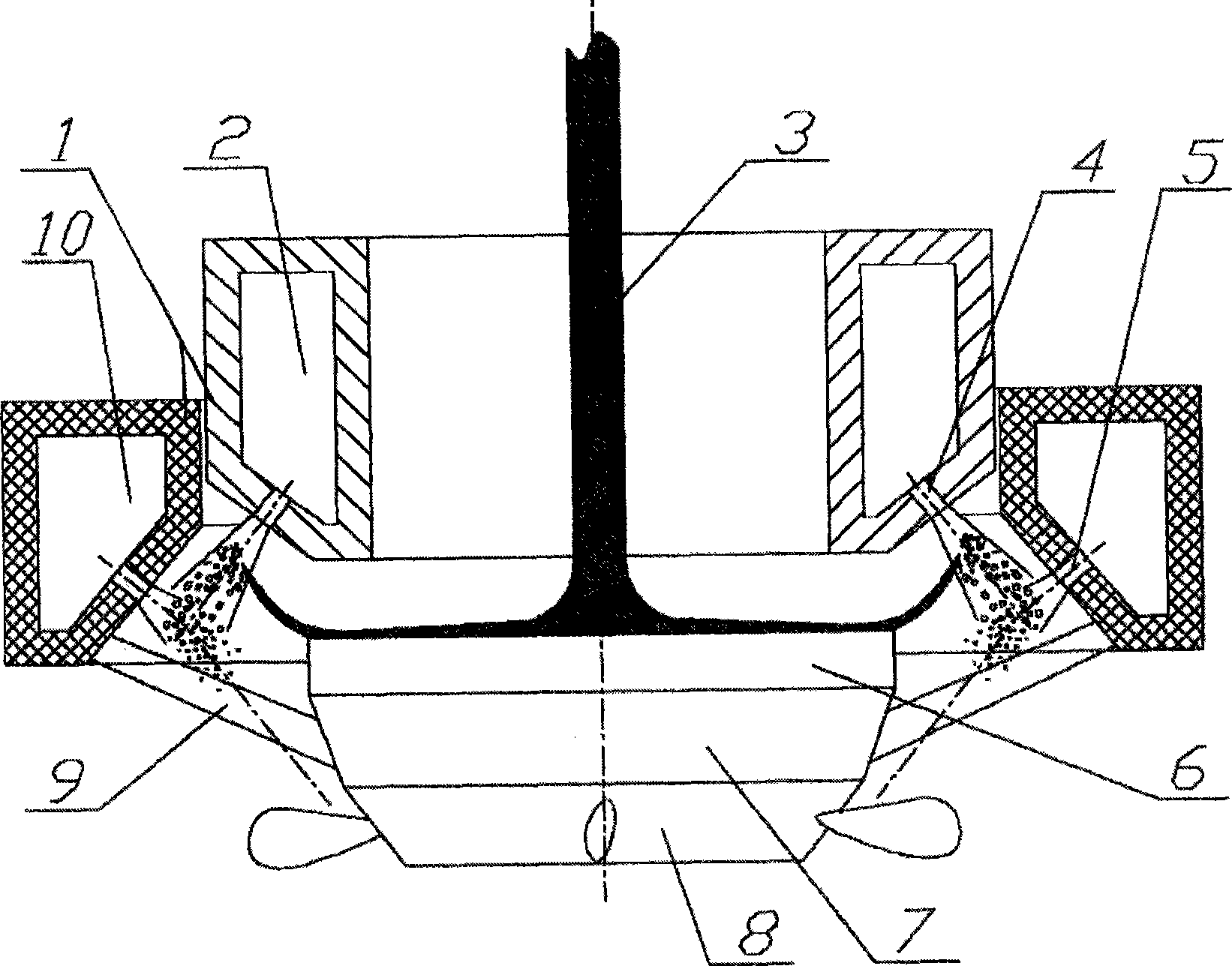

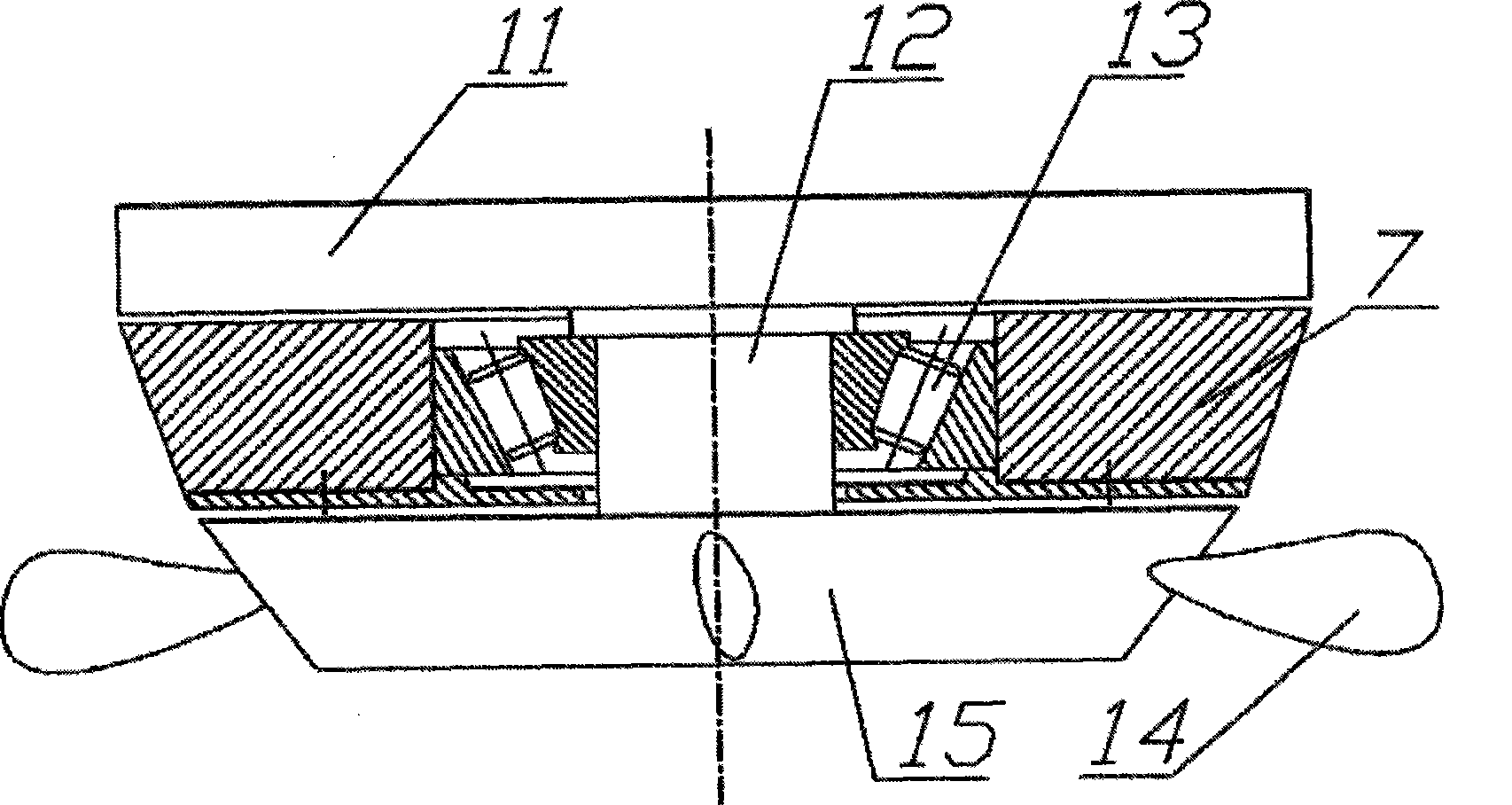

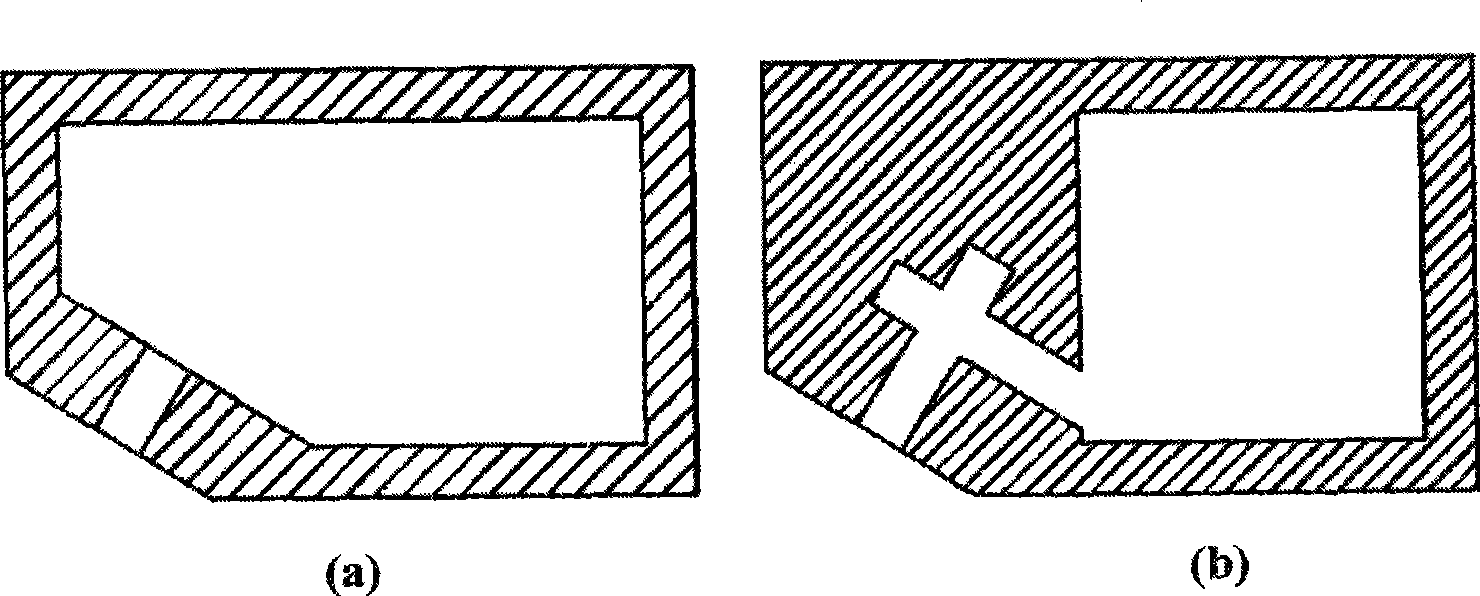

[0028] A preferred embodiment of the present invention is described as follows in conjunction with accompanying drawing: See figure 1 , the rotary film secondary spray metal atomization device, including a supply part of the input liquid metal jet 3, concentric with the center of the input liquid metal jet 3 or even an annular atomization combined nozzle 1, which is arranged below the annular atomized combined nozzle 1 A rotating impact platform 6; the annular atomizing combined nozzle 1 has an upstream nozzle 4 and a downstream nozzle 5, and the direction of the upstream nozzle 4 is flat and the direction of the jet flow is downward centrifugal, so that the impingement input metal jet 3 impacts the impact platform 6 The formed spinning film is formed to realize film forming and breaking; the jet flow direction of the downstream nozzle 5 is in the downward center direction and forms an effective cross angle with the jet flow direction of the upstream nozzle 4, thereby impacting...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com