Molten metal droplet forming device and method of utilizing same to form molten metal droplets

A metal and molten droplet technology is applied in the field of tiny metal droplet forming devices, which can solve the problems of difficulty in producing metal droplets, limitation of the size of metal droplets, and difficulty in controlling the spraying of metal droplets, so as to achieve the effect of size control.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

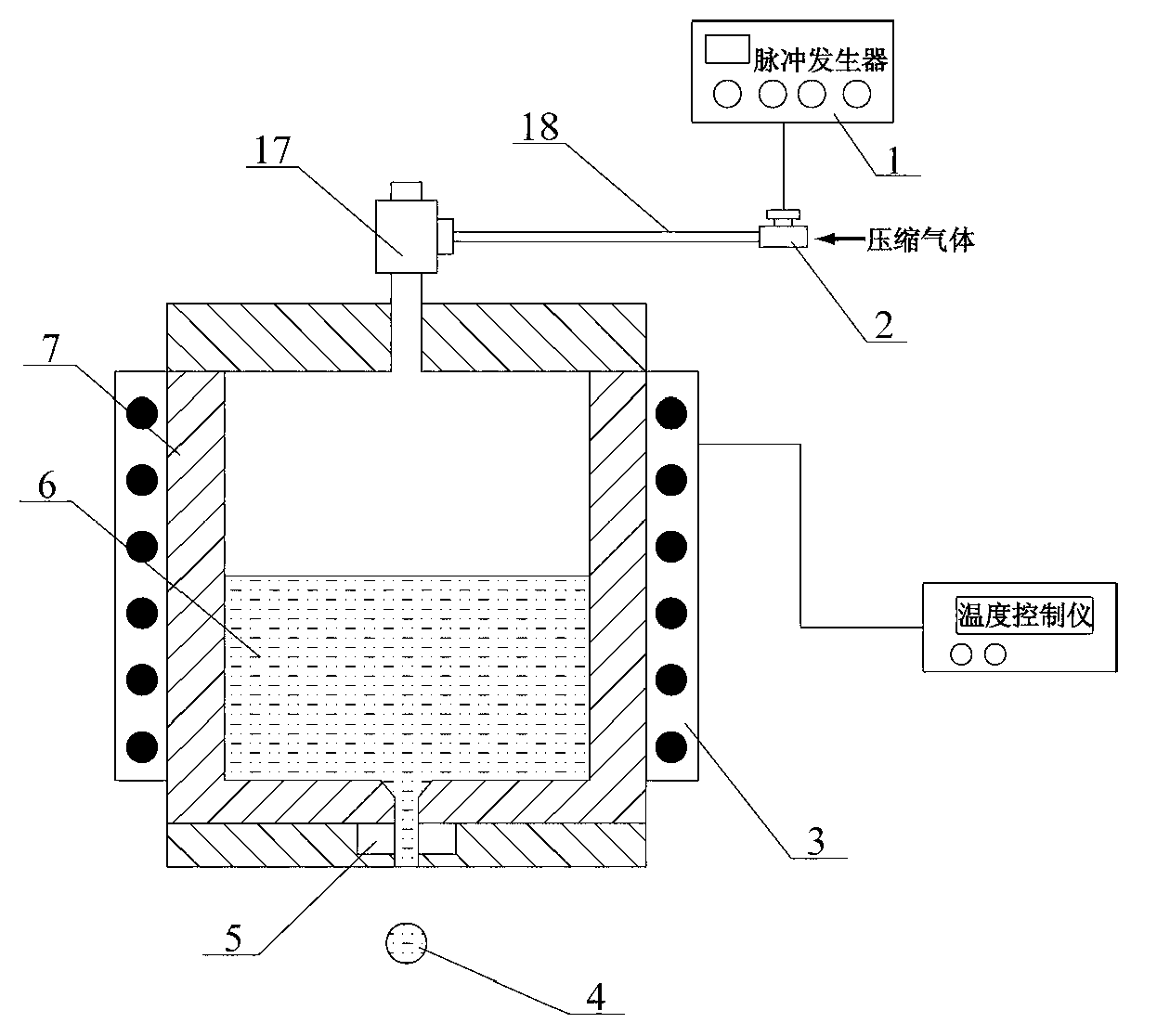

[0024]Example 1: Metal material injection at different pulse frequencies.

[0025] When using the device of the present invention to spray metal materials, the protective gas must be continuously fed into the coaxial gas supply pipeline 15 throughout the experiment to form a local hypoxic environment around the nozzle 5 .

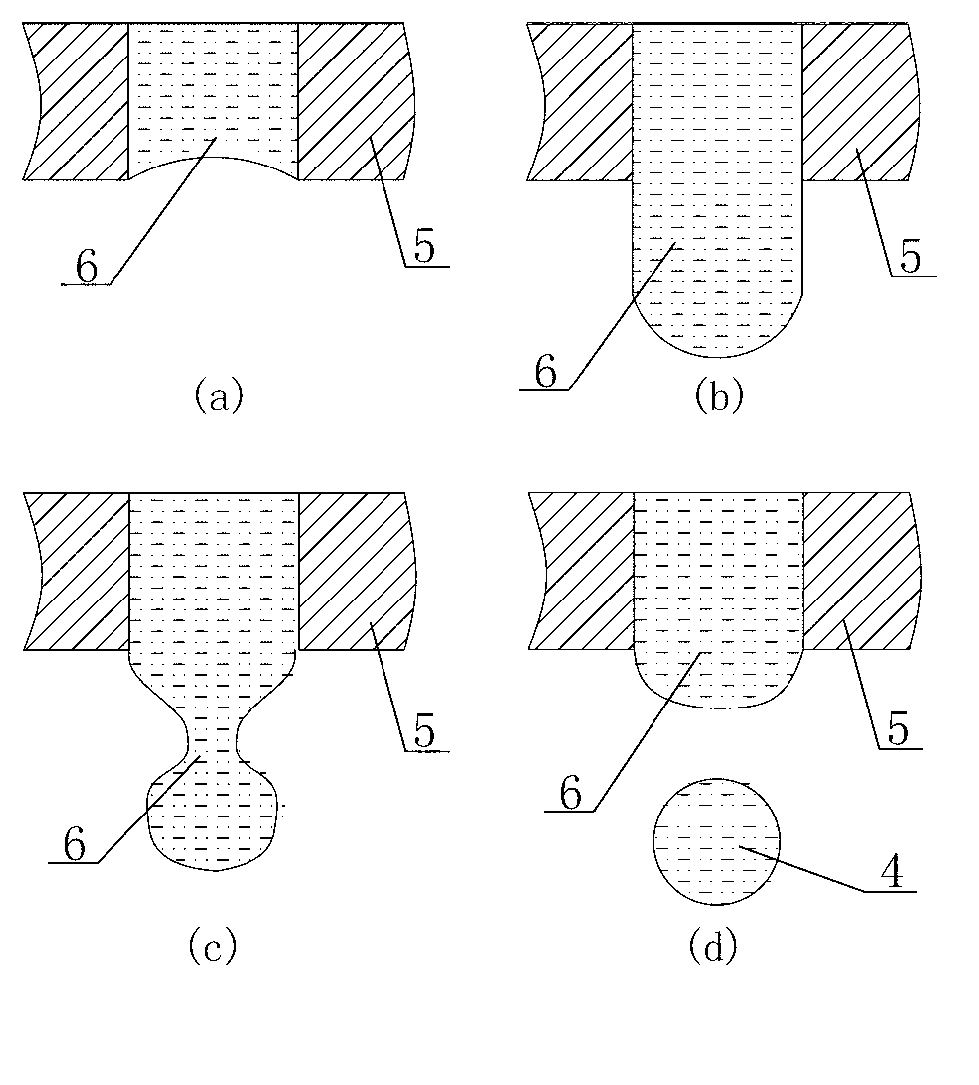

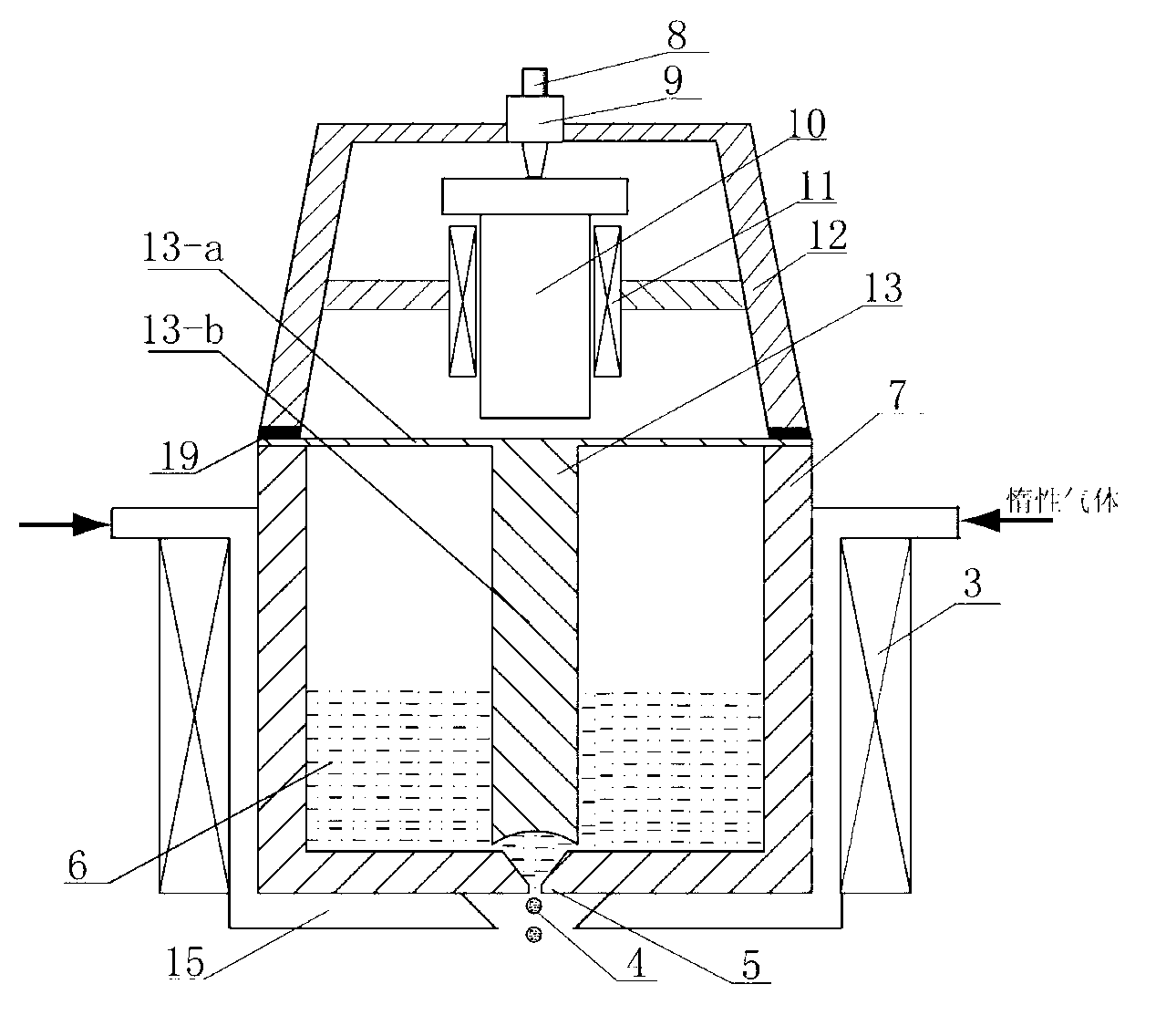

[0026] When using the device of the present invention to carry out metal material injection, first set the heating temperature at 100°C above the melting point of the metal material, use the heating element 3 to heat the metal material until it is completely melted, and then pass through the coil 11 with pulse frequencies of 1 Hz, 2 Hz, 3Hz, 4Hz, 5Hz, 8Hz, 10Hz alternating current to generate the alternating magnetic field of the corresponding frequency, the impact rod 10 placed in the coil 11 will impact the upper end of the "T" rod 13 at the corresponding frequency, and the cylindrical rod 13- Stress waves are generated in b. The stress wave is transmitt...

Embodiment 2

[0028] Example 2: Metal material injection under different pulse widths. When using the device of the present invention to spray metal materials, the protective gas must be continuously fed into the coaxial gas supply pipeline 15 throughout the experiment to form a local hypoxic environment around the nozzle 5 .

[0029] When using the device of the present invention to spray metal materials, first set the heating temperature at 100°C above the melting point of the metal material, use the heating element 3 to heat the metal material until it is completely melted, and then pass through the coil 11 with pulse widths of 2 ms, 3 ms, and 4 ms respectively. , 5ms, 6ms, 8ms, and 10ms of alternating current to generate an alternating magnetic field of corresponding intensity, and the impact rod 10 placed in the coil 11 collides with the upper end of the "T"-shaped rod 13 in the magnetic field of corresponding intensity, and the cylindrical rod 13- Stress waves are generated in b, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com